Preparation method of carbon foam heat insulation material added with hollow ceramic balls

A hollow ceramic and heat insulating material technology, applied in the field of carbon materials, can solve the problems of low use temperature, poor heat insulating performance, high density, etc., and achieve the effects of uniform cells, high safety, and reliable working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

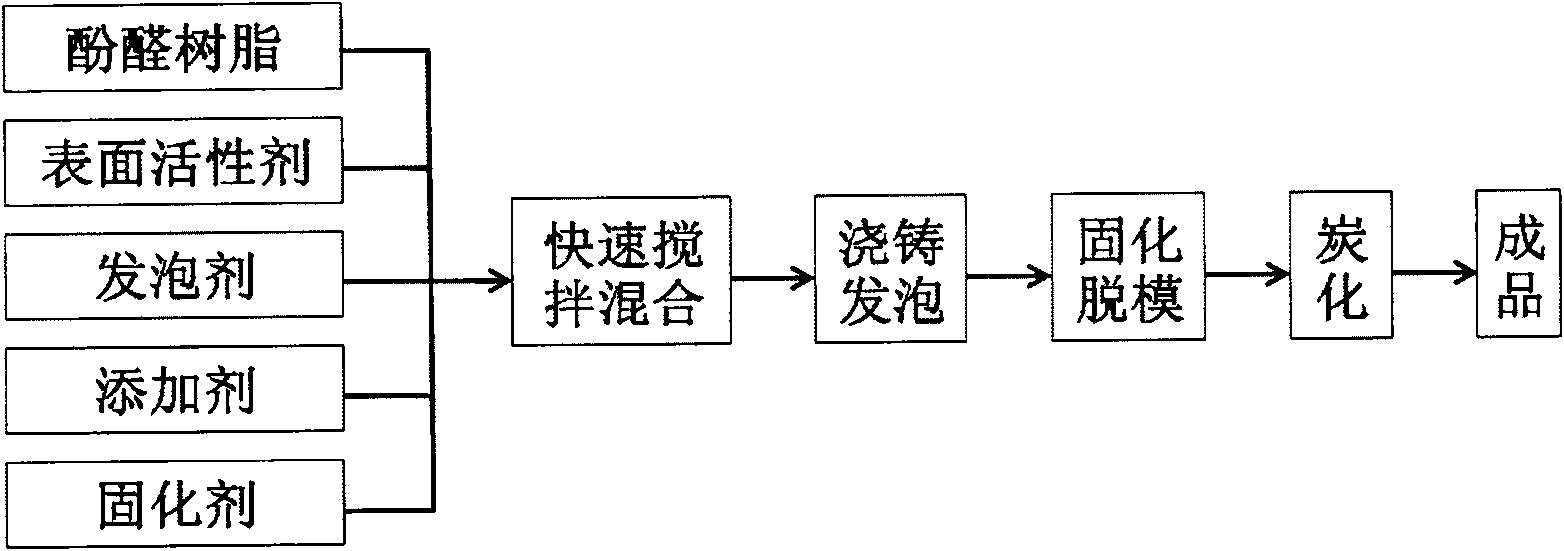

Method used

Image

Examples

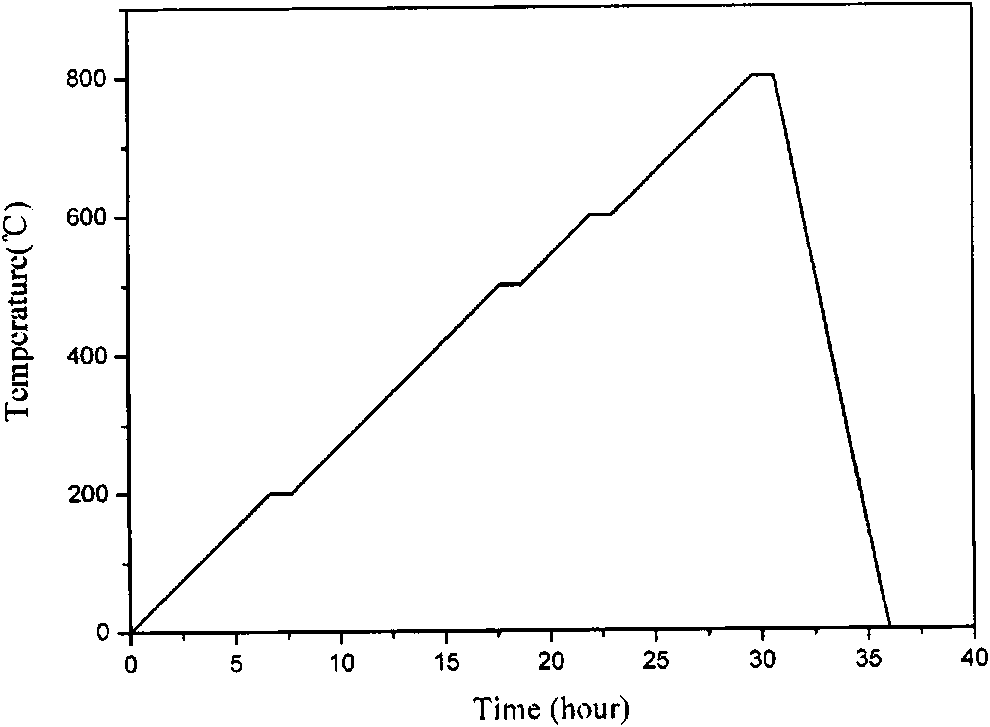

Embodiment 1

[0038] Weigh the raw materials of each component according to the foaming formula of 100 parts of phenolic resin, 4 parts of surfactant, 2 parts of foaming agent and 7 parts of curing agent, add surfactant and foaming agent in sequence in the phenolic resin, and mechanically stir 1 hour, then ultrasonically disperse for 2 hours to make it evenly dispersed. Then, under normal temperature and pressure, after adding a curing agent, a phenolic foam is obtained. After shelling the phenolic foam, put it into a vacuum carbonization furnace and heat it to 800°C at an average rate of 0.5°C / min under vacuum conditions to obtain a carbon foam insulation material. Wherein, the phenolic resin is a liquid resole phenolic resin (viscosity (25°C): 100-120mPa·s); wherein, the surfactant is Tween-80; wherein, the foaming agent is n-pentane; wherein, the curing agent is hydrochloric acid .

[0039] Performance test on this carbon foam insulation material: the density of the material is 0.172g / ...

Embodiment 2

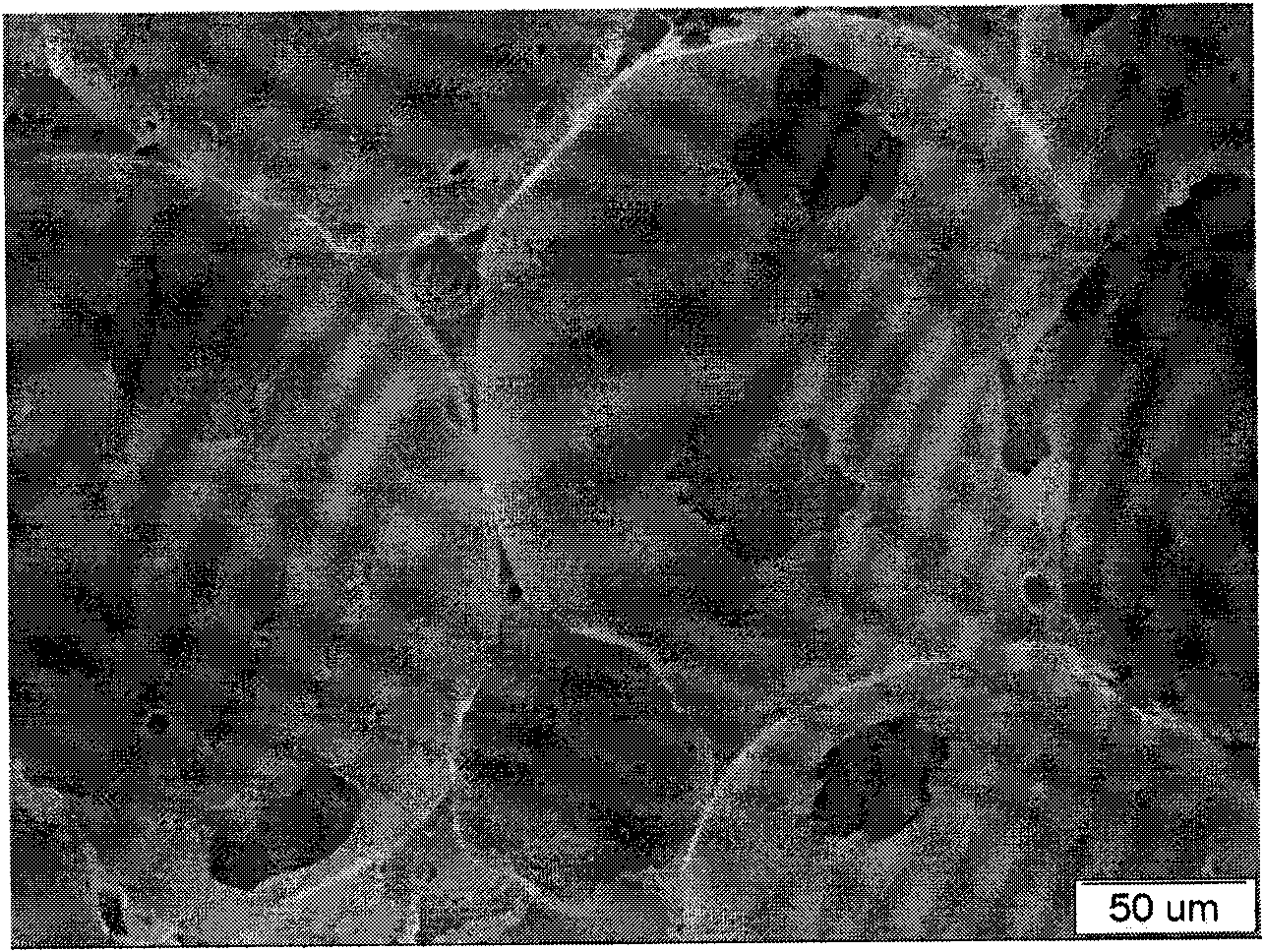

[0041] Weigh each component raw material according to the foaming formula of 100 parts of phenolic resin, 4 parts of surfactant, 2 parts of blowing agent, 7 parts of curing agent, add surfactant, blowing agent in sequence in phenolic resin, and add to 1 wt% hollow ceramic microspheres were added to the mixture. Stir mechanically for 1 hour, then ultrasonically disperse for 2 hours to make the dispersion uniform. Then, under normal temperature and pressure, after adding a curing agent, a phenolic foam is obtained. After the phenolic foam is shelled, it is placed in a vacuum carbonization furnace, and heated to 800°C at an average rate of 0.5°C / min under vacuum conditions to obtain a reinforced carbon foam material. Its microstructure is as follows: image 3 shown. Wherein, the phenolic resin is a liquid resole phenolic resin (viscosity (25°C): 100-120mPa·s); wherein, the surfactant is Tween-80; wherein, the foaming agent is n-pentane; wherein, the curing agent is hydrochloric...

Embodiment 3

[0044] Weigh each component raw material according to the foaming formula of 100 parts of phenolic resin, 4 parts of surfactant, 2 parts of whipping agent, 7 parts of curing agent, add surfactant, whipping agent successively in liquid phenolic resin, and 2 wt% hollow ceramic microspheres were added to the mixture. Stir mechanically for 1 hour, then ultrasonically disperse for 2 hours to make the dispersion uniform. Under normal temperature and pressure, after adding curing agent, phenolic foam is obtained. After the phenolic foam is shelled, it is placed in a vacuum carbonization furnace, and heated to 800°C at an average rate of 0.5°C / min under vacuum conditions to obtain a reinforced carbon foam material. Its microstructure is as follows: Figure 4 shown. Wherein, the phenolic resin is a liquid resole phenolic resin (viscosity (25°C): 100-120mPa·s); wherein, the surfactant is Tween-80; wherein, the foaming agent is n-pentane; wherein, the curing agent is hydrochloric acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com