Road material produced by using Bayer process red mud

A technology of Bayer red mud and road materials, which is applied in the field of road materials produced by using Bayer red mud to achieve the effect of saving natural resources and road engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A road material produced using Bayer red mud, comprising a road base layer, a road water stabilization layer and a road surface layer, wherein the road base layer is made of the following raw materials in parts by weight: 4 parts of low-temperature ceramic curing agent, red mud 96 parts, 30 parts of water, the road water stabilization layer is made of the following raw materials in parts by weight: 8 parts of low-temperature ceramic curing agent, 20 parts of red mud, 36 parts of slag, 36 parts of centimeter gravel, 20 parts of water, all The road surface layer is made of the following raw materials in parts by weight: 30 parts of low-temperature ceramic curing agent, 2 parts of red mud, 32 parts of sand, 34 parts of gravel, and 40 parts of water.

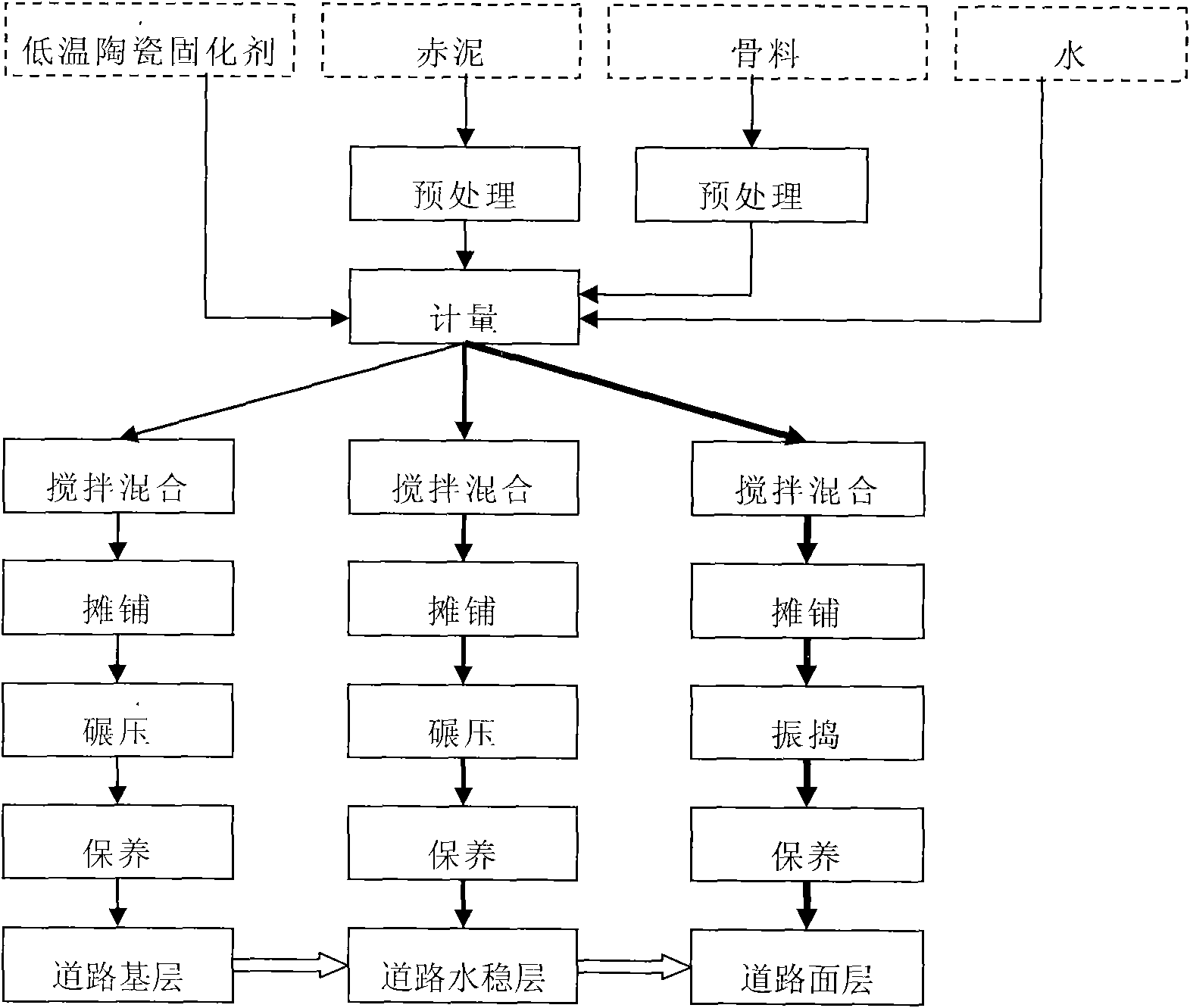

[0027] Such as figure 1 As shown, the preparation of road materials produced from Bayer process red mud:

[0028] Measure the amount of each material in the road base according to the formula, force stirring for 5 minutes, a...

Embodiment 2

[0033] A road material produced by using Bayer red mud, comprising a road base, a road water stabilization layer and a road surface layer, wherein the road base is made of the following raw materials in parts by weight: 25 parts of low-temperature ceramic curing agent, red mud 45 parts, 30 parts of silt soil, 16 parts of water; the road water stabilization layer is made of the following raw materials in parts by weight: 20 parts of low-temperature ceramic curing agent, 20 parts of red mud, 60 parts of centimeter gravel, 15 parts of water ; The production road surface layer is made of the following raw materials in parts by weight: 10 parts of low-temperature ceramic curing agent, 10 parts of red mud, 30 parts of sand, 50 parts of gravel, and 10 parts of water.

[0034] Such as figure 1 As shown, the preparation of road materials produced from Bayer process red mud:

[0035] Measure the amount of various substances in the road base according to the formula, force stirring for ...

Embodiment 3

[0040] A road material produced by using the Bayer process red mud, including a road base layer, a road water stabilization layer and a road surface layer, wherein the road base layer is made of the following raw materials in parts by weight: 8 parts of low-temperature ceramic curing agent, red mud 62 parts, 30 parts of fly ash, and 25 parts of water; the road water stabilization layer is made of the following raw materials in parts by weight: 14 parts of low-temperature ceramic curing agent, 15 parts of red mud, 71 parts of sand, and 17 parts of water; The production road surface layer is made of the following raw materials in parts by weight: 20 parts of low-temperature ceramic curing agent, 6 parts of red mud, 26 parts of sand, 48 parts of gravel, and 25 parts of water.

[0041] Such as figure 1 As shown, the Bayer process red mud production road material is prepared with the same embodiment 2.

[0042] According to the above ratio and method, the performance of the road m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com