Guided jaw overrunning clutch

An overrunning clutch, guided technology, applied in the field of mechanical transmission, can solve the problems of low effective utilization rate, high friction strength of spline tooth surface, difficult to miniaturize, etc., and achieves simple and convenient use and maintenance, mature manufacturing and assembly technology, Reliable effect of engagement and disengagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

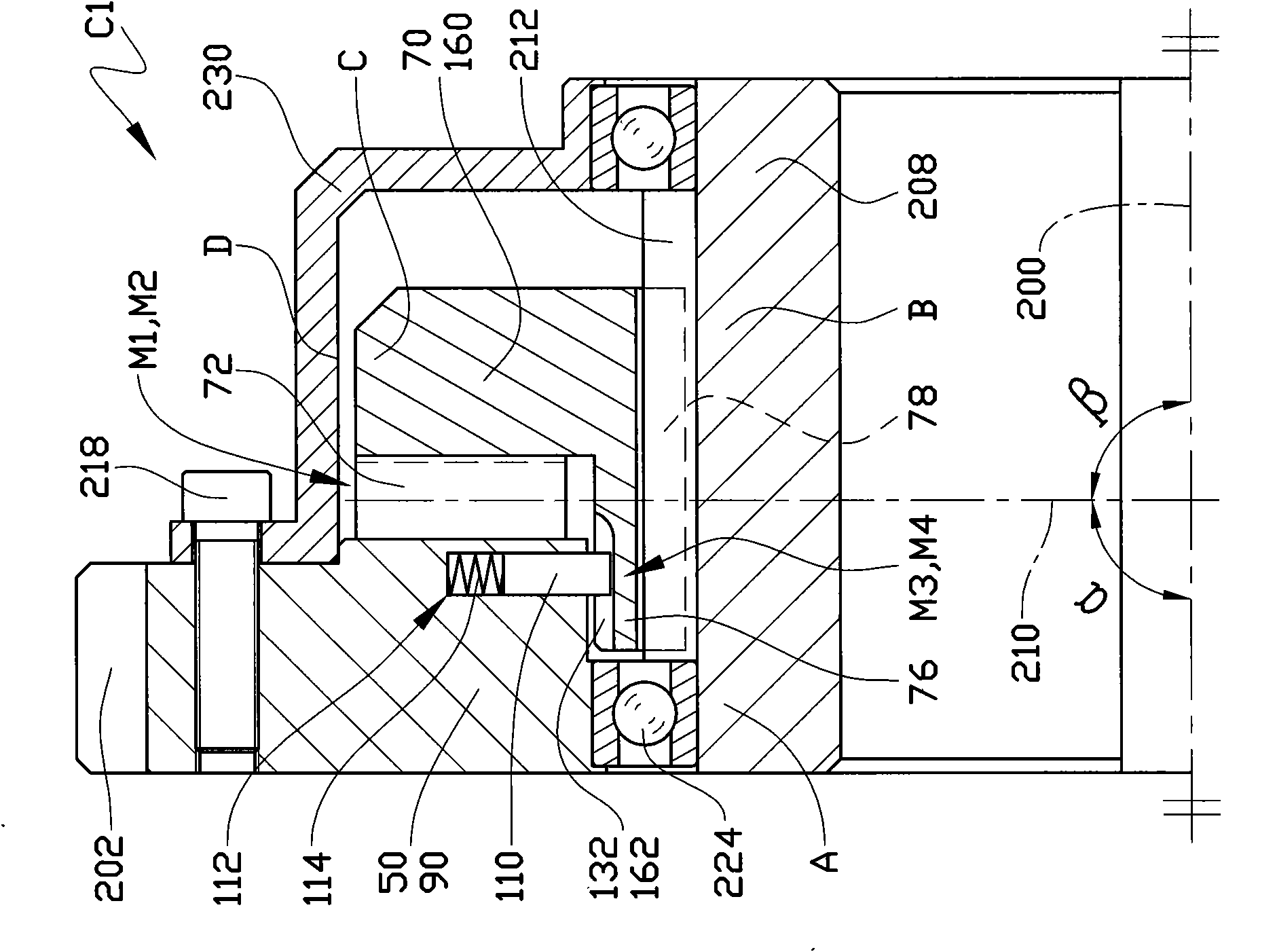

[0040] Embodiment 1: Wheel-shaft transmission type one-way overrunning clutch C1 with packaging form 1

[0041] see figure 1 , the fixed ring 50 of the overrunning clutch C1 and the supporting shell 230 are fastened into one body by screws 218, and the two are axially fixed on the second rotating member 208 by means of two bearings 224, so that the force transmission fitting mechanism M1 and the lead-out mechanism M2 , the introduction mechanism M3 and the fixed-point actuation mechanism M4 are encapsulated, and can rotate around the axis 200 individually or integrally.

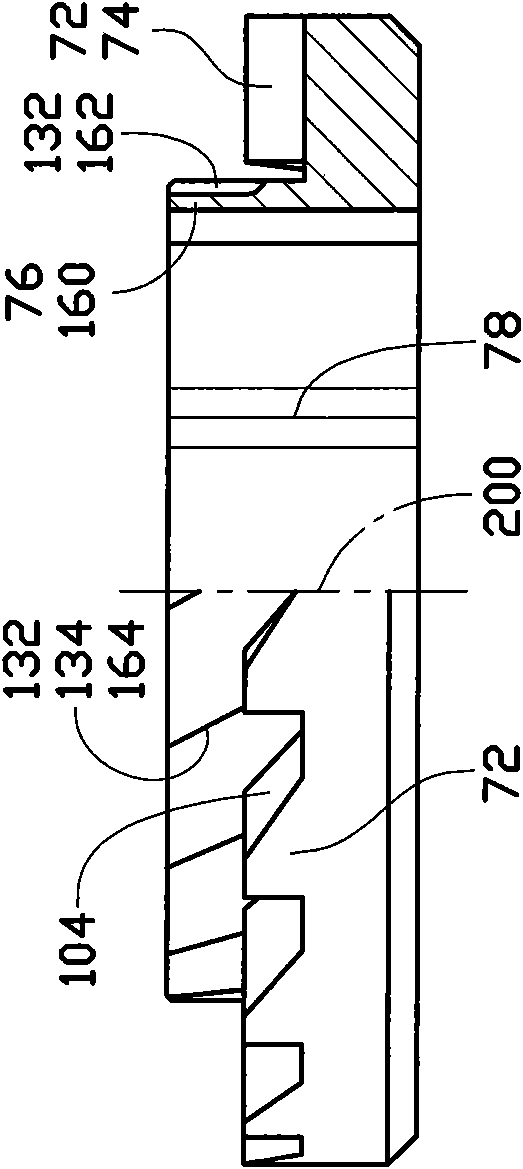

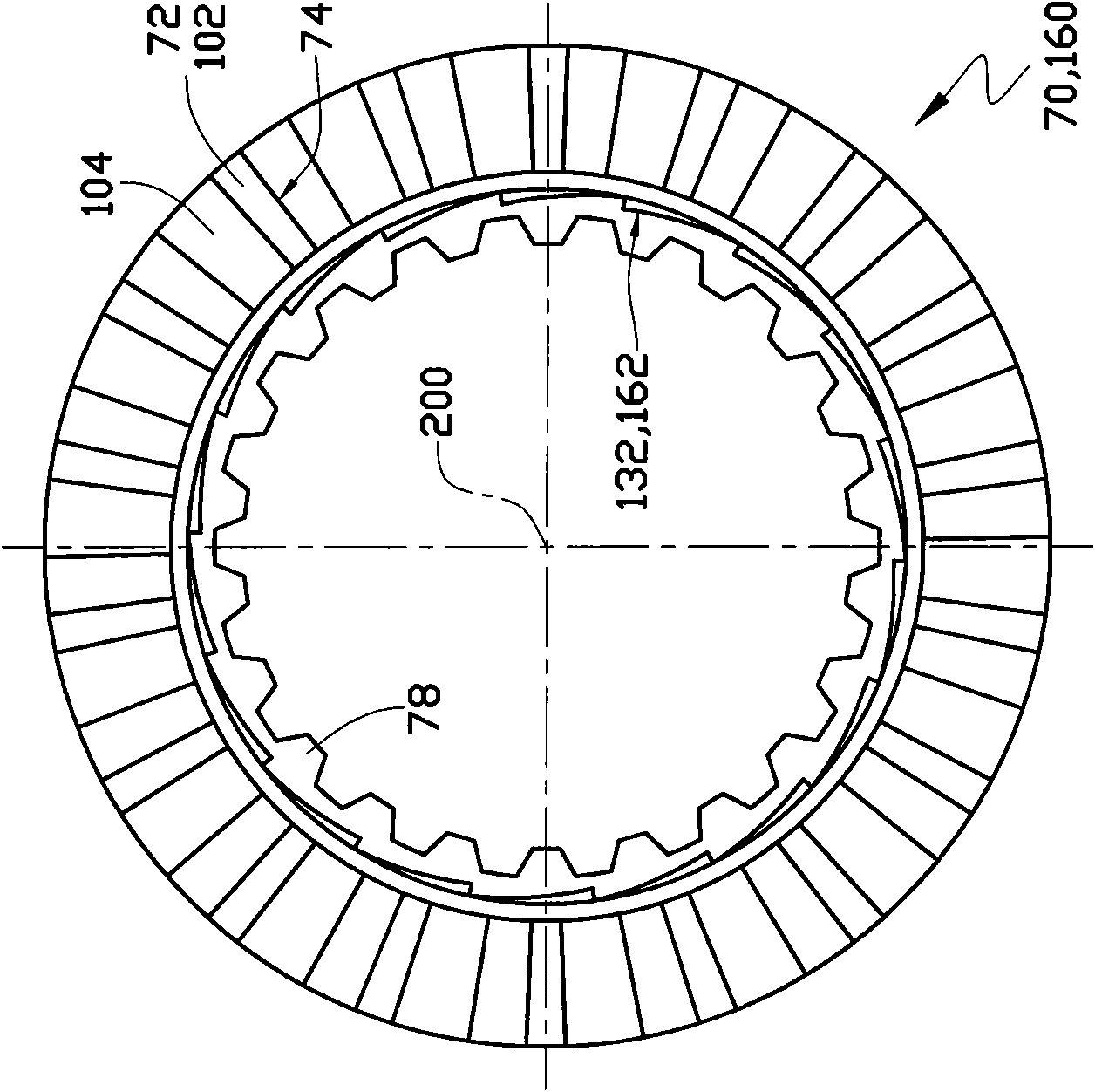

[0042] The force transmission fitting mechanism M1 includes a fixed ring 50 and a moving ring 70 that are fitted axially relative to each other, see figure 1 ~ Figure 3. The force transmission teeth 72 uniformly distributed on the circumference of the moving ring 70 preferably have a force transmission tooth flank 74 parallel to the axis 200 , and the other tooth flank is an auxiliary lead-out tooth flank 1...

Embodiment 2

[0064] Embodiment 2: Wheel-shaft transmission type one-way overrunning clutch C2 with package form 2

[0065] control figure 1 , 4 , the overrunning clutch C2 is a deformation of the overrunning clutch C1, and it radially outwards the moving ring 70 and the second rotating member 208 of the latter, adding a pawl holding mechanism M8, a damping mechanism M9 and a rigid integral body with the fixed ring 50. The first rotating member 206 .

[0066] see Figure 4 , the damping mechanism M9 includes a damping through hole parallel to the axis 200 on the second rotating member 208, a cylindrical damping member 226 movably embedded in it, a spring and a threaded plug assembly 228, and a middle section formed in the damping through hole Corresponding to the breathing hole for damping oil or gas in and out of the spring part. Apparently, this structure is more suitable for the solution where the spline tooth pair has a lead-in function.

[0067] Different from the bidirectional da...

Embodiment 3

[0077] Embodiment 3: Shaft-shaft transmission type two-way overrunning clutch C3 without encapsulation

[0078] see figure 1 , 8 The two-way overrunning clutch C3 is essentially an organic superposition of two one-way overrunning clutches C1 with opposite working directions (the bearing 224 and the supporting shell 230 are removed), and an actuation for causing the fixed-point actuation mechanism M4a or M4b to fail is added. The selection mechanism M5, the reversing mechanism M6 used to specify the working rotation direction of the clutch, the reversing drive mechanism M7 that controls the mechanism, and the optional pawl holding mechanism M8 and a small number of auxiliary components.

[0079] In addition to the fact that the force transmission teeth 52 and 72 have two force transmission tooth flanks 54 and 74 parallel to the axis 200 for the purpose of transmitting torque in the two circumferential directions, and the circumferential degree of freedom in the fitted state sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com