Method for manufacturing gan-based nitride semiconductor self-supporting substrate

A nitride semiconductor and manufacturing method technology, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, chemical instruments and methods, etc., can solve the problems of low yield, difficulty in manufacturing large-size self-supporting substrates, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In the present invention, a method for producing a GaN self-supporting substrate using the HVPE method is given as an example.

[0049] This embodiment uses the following steps 1) to 5) as basic steps.

[0050] 1) High temperature nitriding process of sapphire substrate

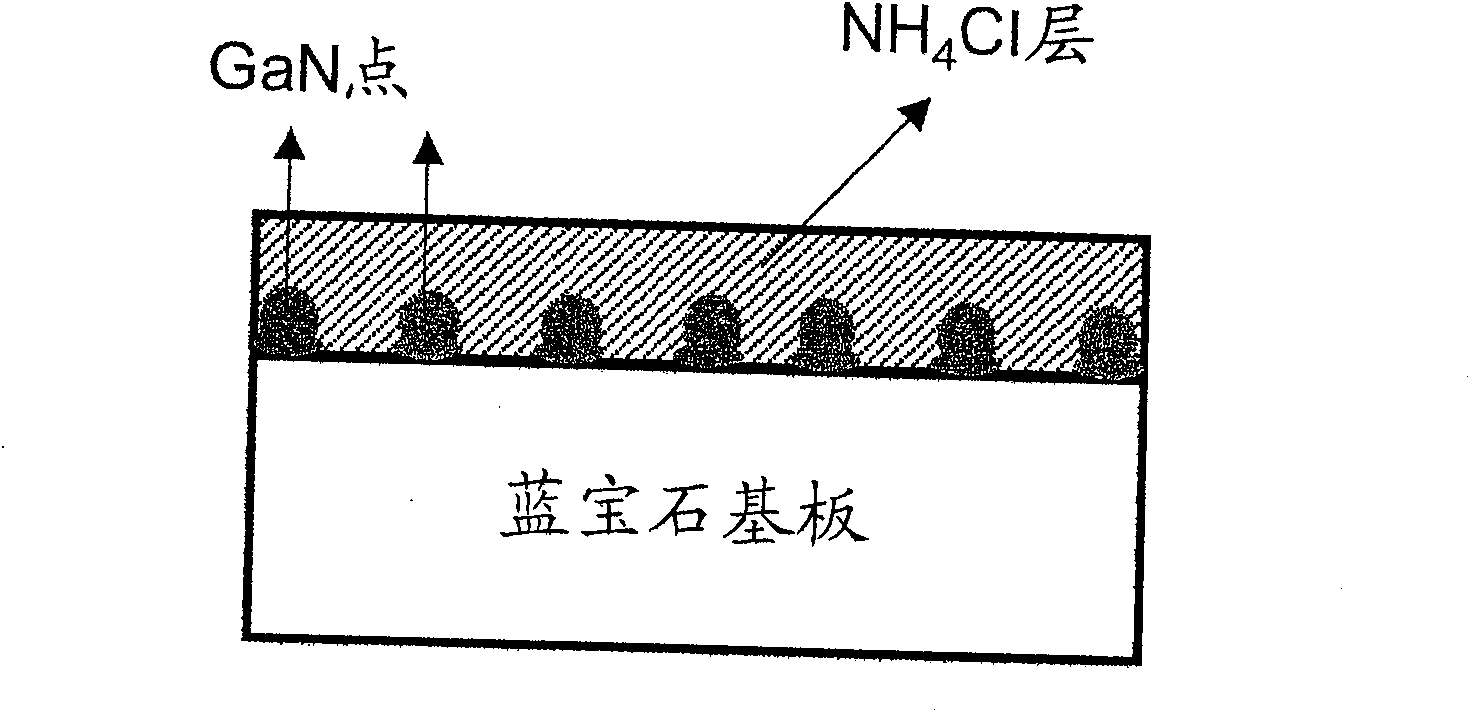

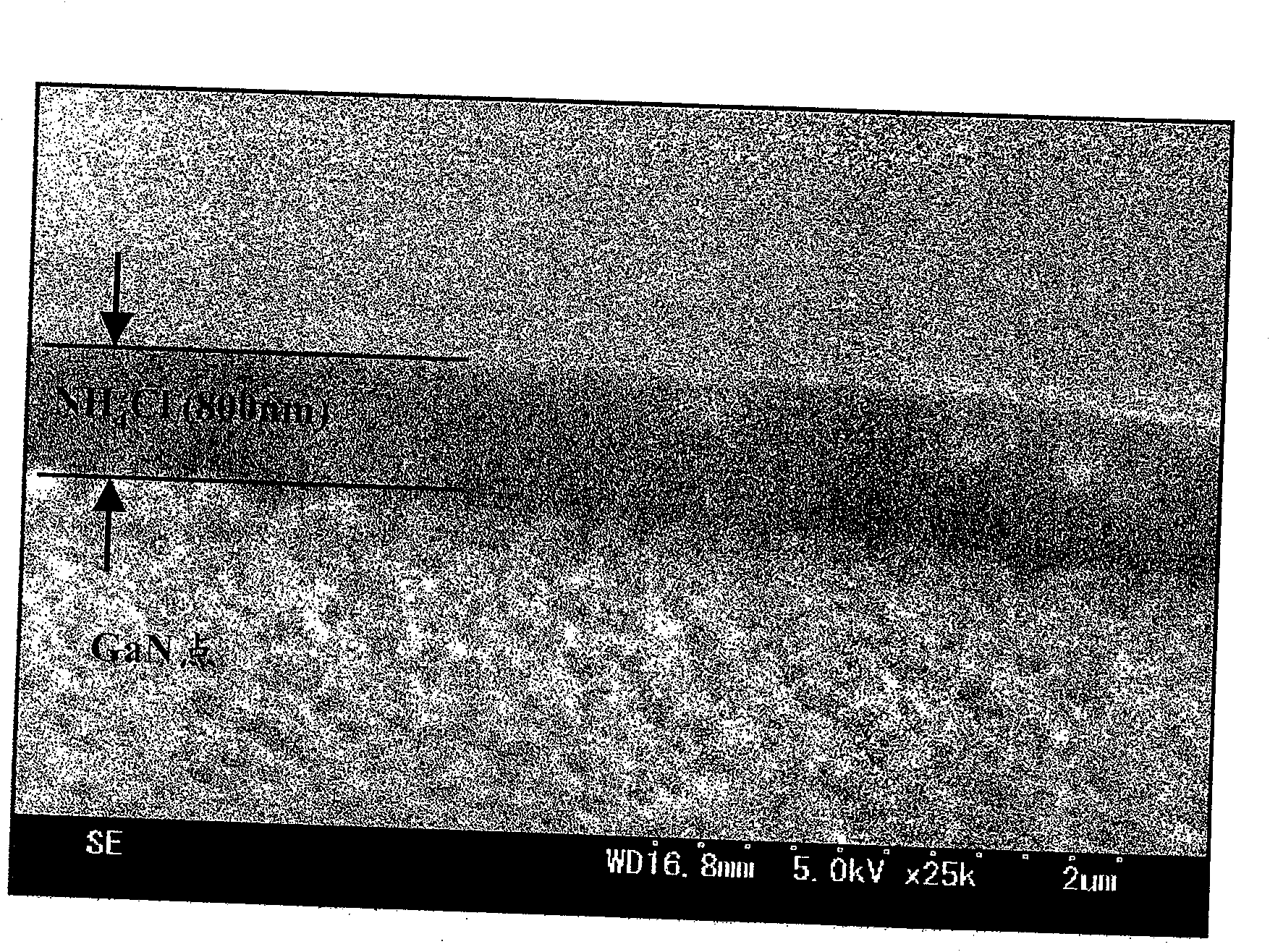

[0051] 2) NH 4 Cl layer and GaN dot formation process

[0052] 3) Growth process of low temperature GaN buffer layer

[0053] 4) Formation process of high-temperature thick-film GaN layer

[0054] 5) Self-stripping process of GaN self-supporting substrate

[0055] Furthermore, in this example, a c-plane grown GaN self-supporting substrate was obtained through steps 1) to 5).

[0056] The above steps 1) to 5) will be described in detail below.

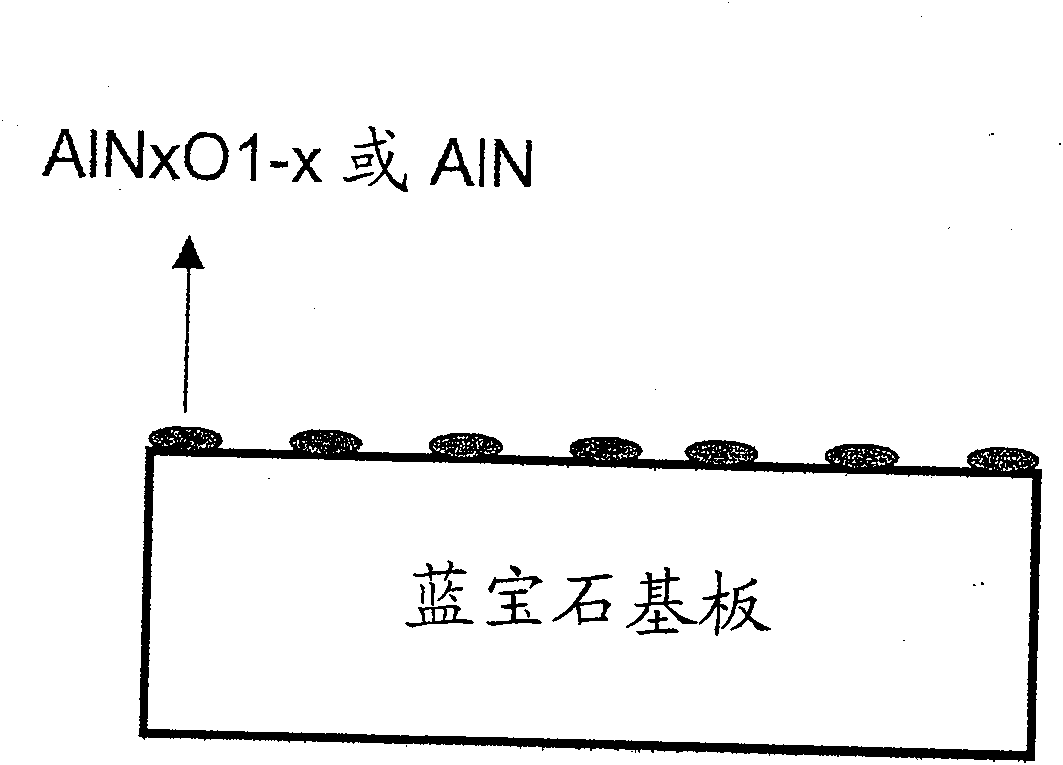

[0057] 1) High temperature nitriding process of sapphire substrate

[0058] This process is to locally form AlN on the surface of the sapphire substrate through high-temperature nitriding treatment of the sapphire substrate in the HVPE reactor X o 1-X (0<...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com