Method for manufacturing plasma display panel

A technology of a plasma display and a manufacturing method, which are applied in the direction of alternating current plasma display panels, the manufacture of discharge tubes/lamps, and the manufacture of cold cathodes, etc., can solve the problems of reducing the attenuation rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

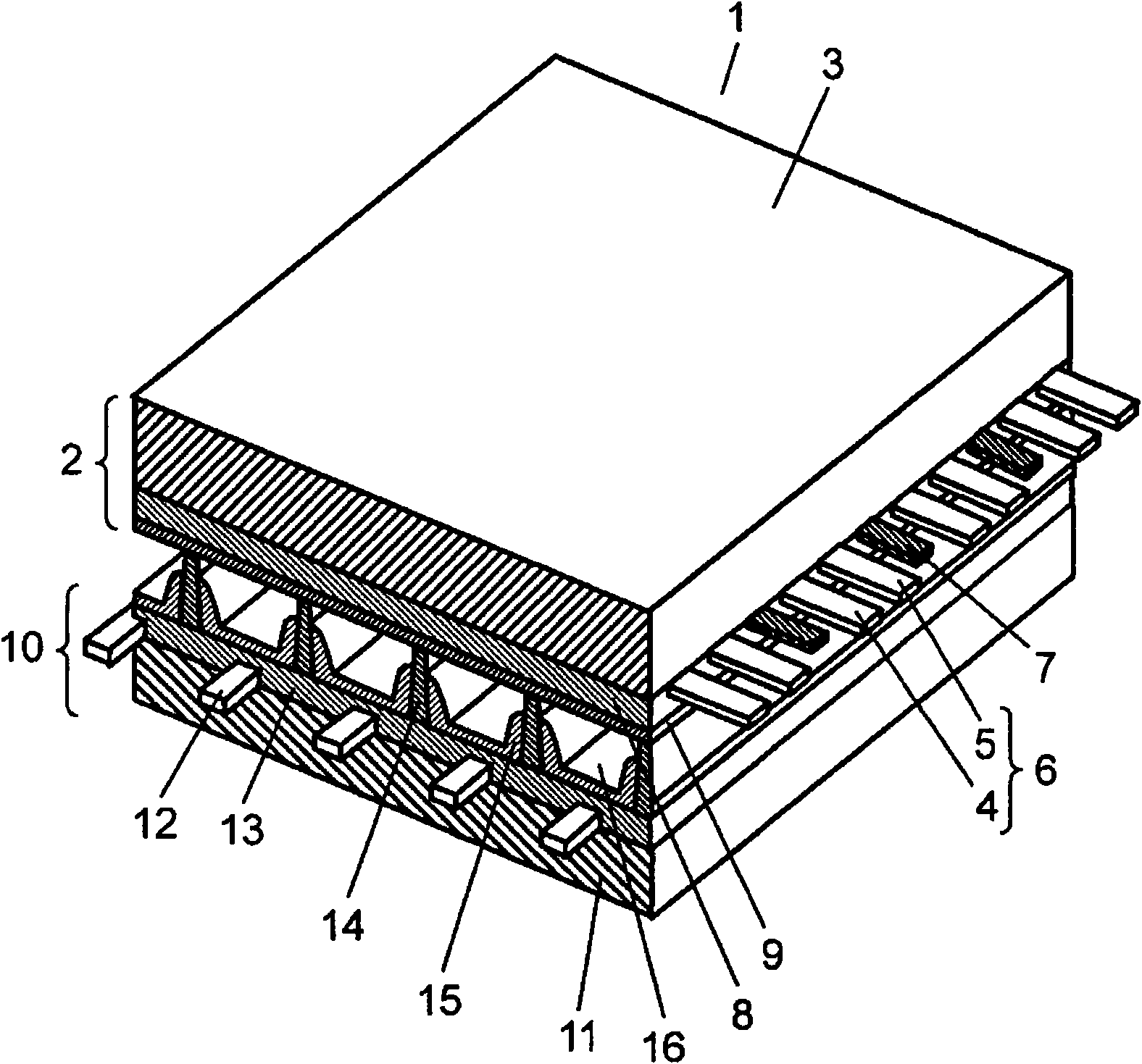

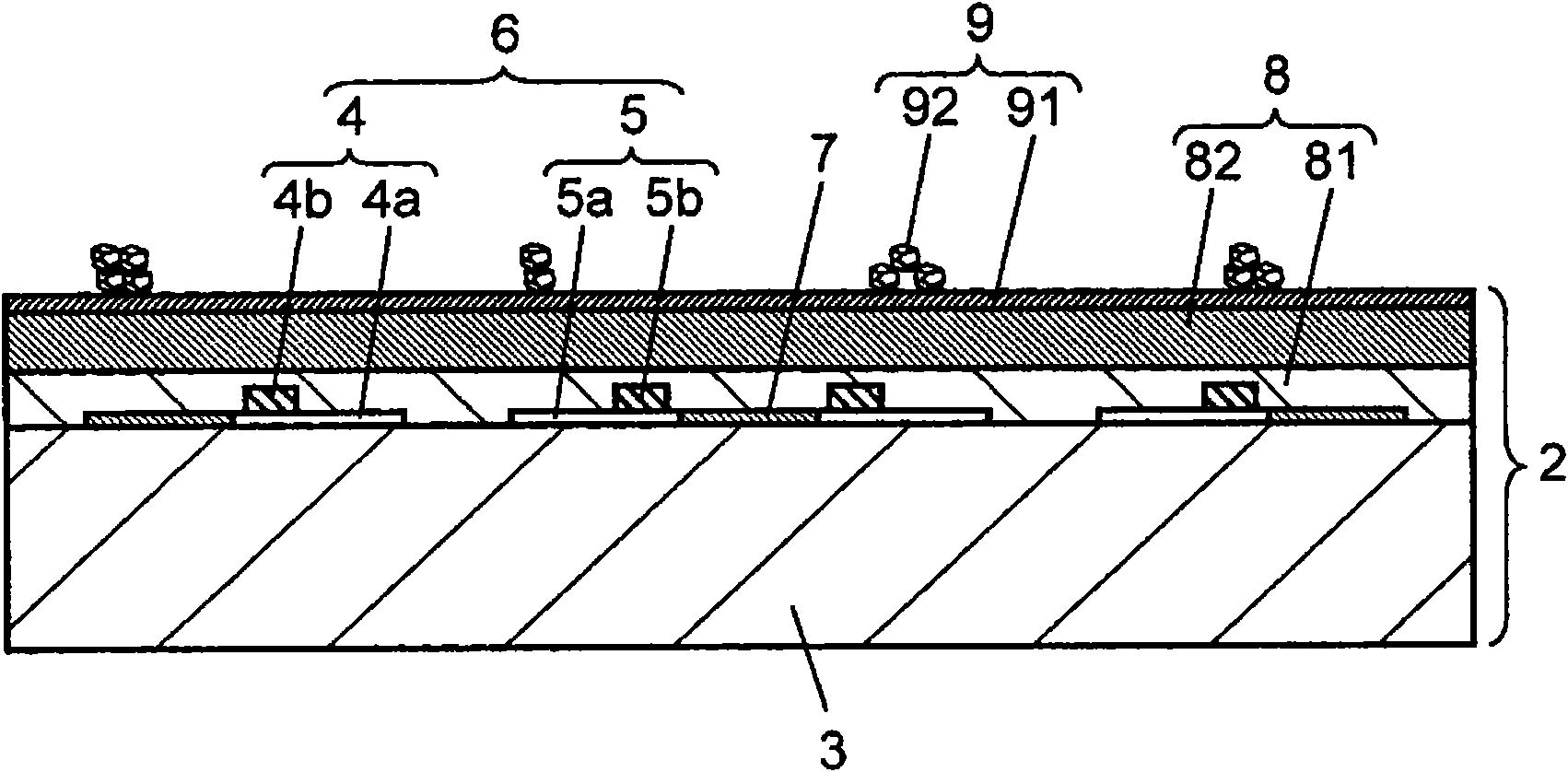

[0048] figure 1 It is a perspective view showing the structure of PDP 1 manufactured by the PDP manufacturing method in the embodiment of the present invention. Front panel 2 including front glass substrate 3 and rear panel 10 including rear glass substrate 11 are arranged to face each other, and the outer periphery thereof is hermetically sealed with a sealing material including glass frit. In the discharge space 16 inside the PDP 1, discharge gases such as neon (Ne) and xenon (Xe) are sealed at a pressure of 53.3 kPa to 80.0 kPa. On the front glass substrate 3 of the front panel 2, a pair of strip-shaped display electrodes 6 and black stripes (light shielding layers) 7 composed of scan electrodes 4 and sustain electrodes 5 are arranged in parallel to each other. A dielectric layer 8 functioning as a capacitor is formed on the front glass substrate 3 to cover the display electrodes 6 and the light shielding layer 7, and a protective layer 9 made of magnesium oxide (MgO) or t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com