Laminated wiring board and method for manufacturing the same

A technology for wiring substrates and manufacturing methods, which is applied in the directions of multilayer circuit manufacturing, printed circuit manufacturing, and electrical connection formation of printed components, which can solve problems such as unevenness, roughening of conductive layers, and complicated manufacturing, and reduce the number of processes , high connection reliability, simple and easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

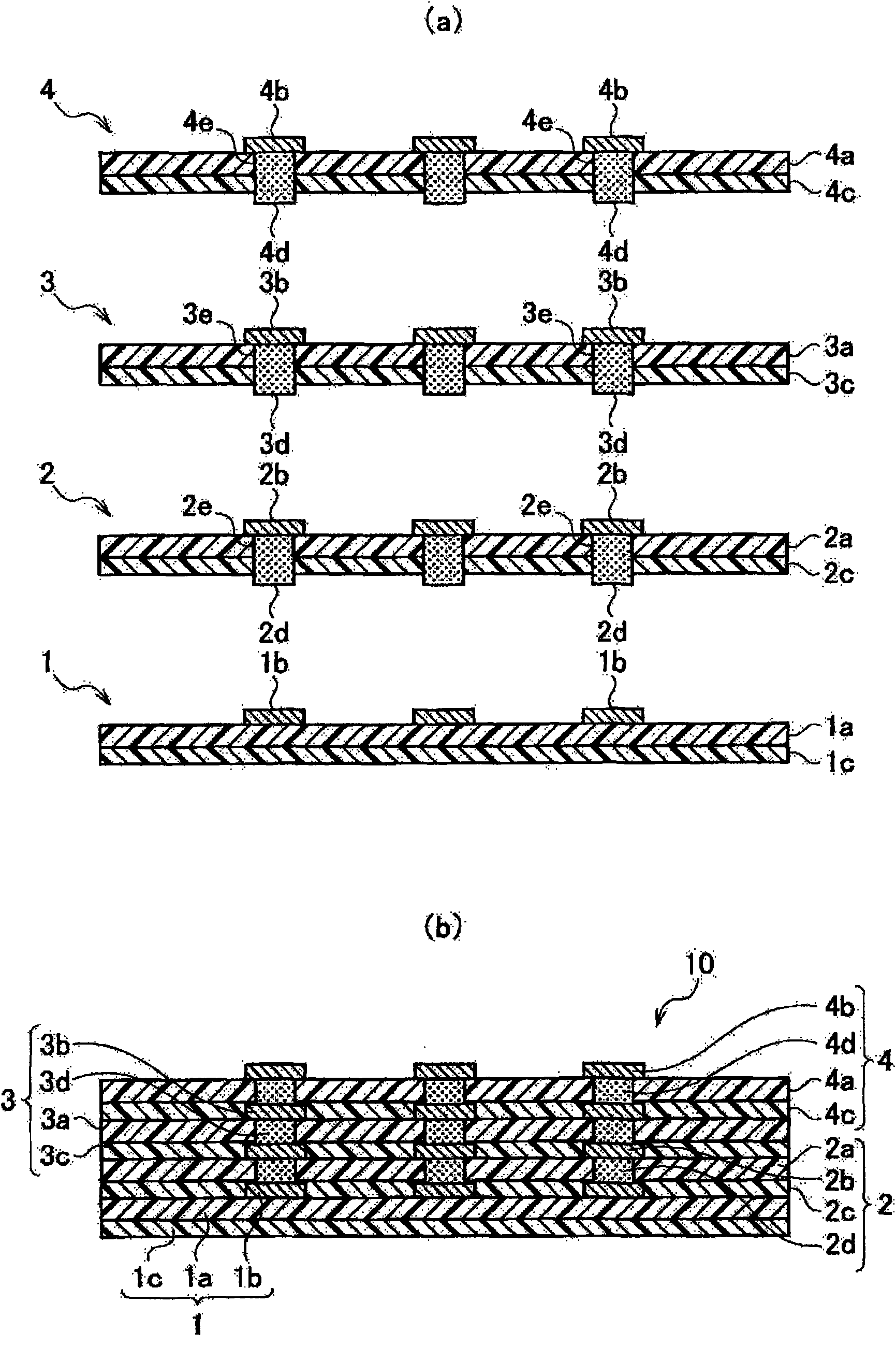

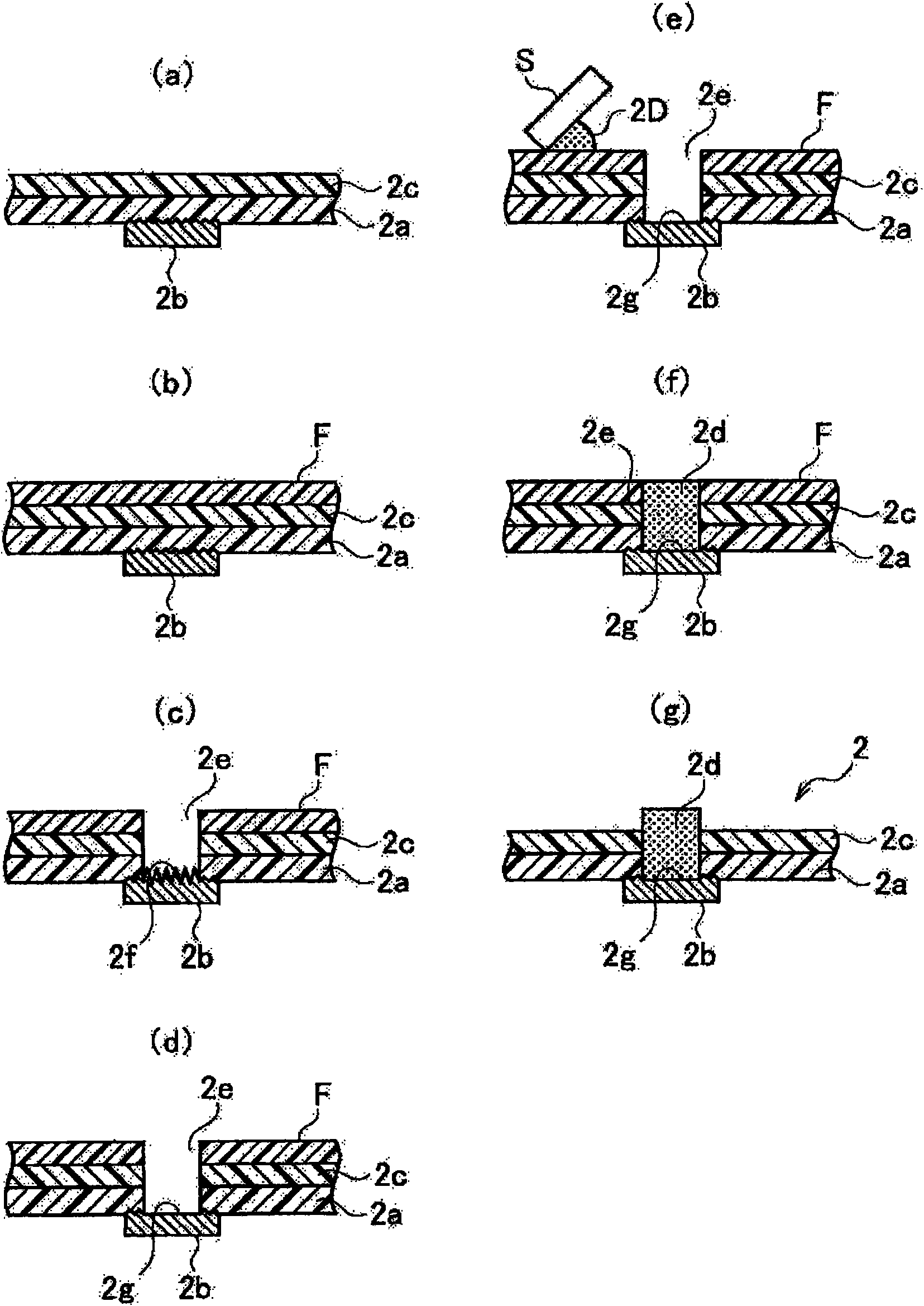

[0030] Below, refer to figure 1 and figure 2 One embodiment of the laminated wiring board of the present invention and its manufacturing method will be described. figure 1 It is a schematic cross-sectional view for explaining a method of laminating a plurality of wiring board base materials to manufacture a laminated wiring board. figure 1 (a) shows each wiring board base material before assembly. figure 1 (b) shows the structure of the assembled laminated wiring board. figure 2 (a)~ figure 2 (g) is used for step-by-step instructions figure 1 An enlarged cross-sectional view of a main part of the manufacturing method of each wiring board base material in .

[0031] First, if figure 1 As shown in (a), first to fourth wiring board base materials 1 to 4 adjacent to each other in the vertical direction are arranged so as to overlap each other. The above-mentioned first wiring board base material 1 has, for example, a first insulating substrate 1a made of a polyamid...

PUM

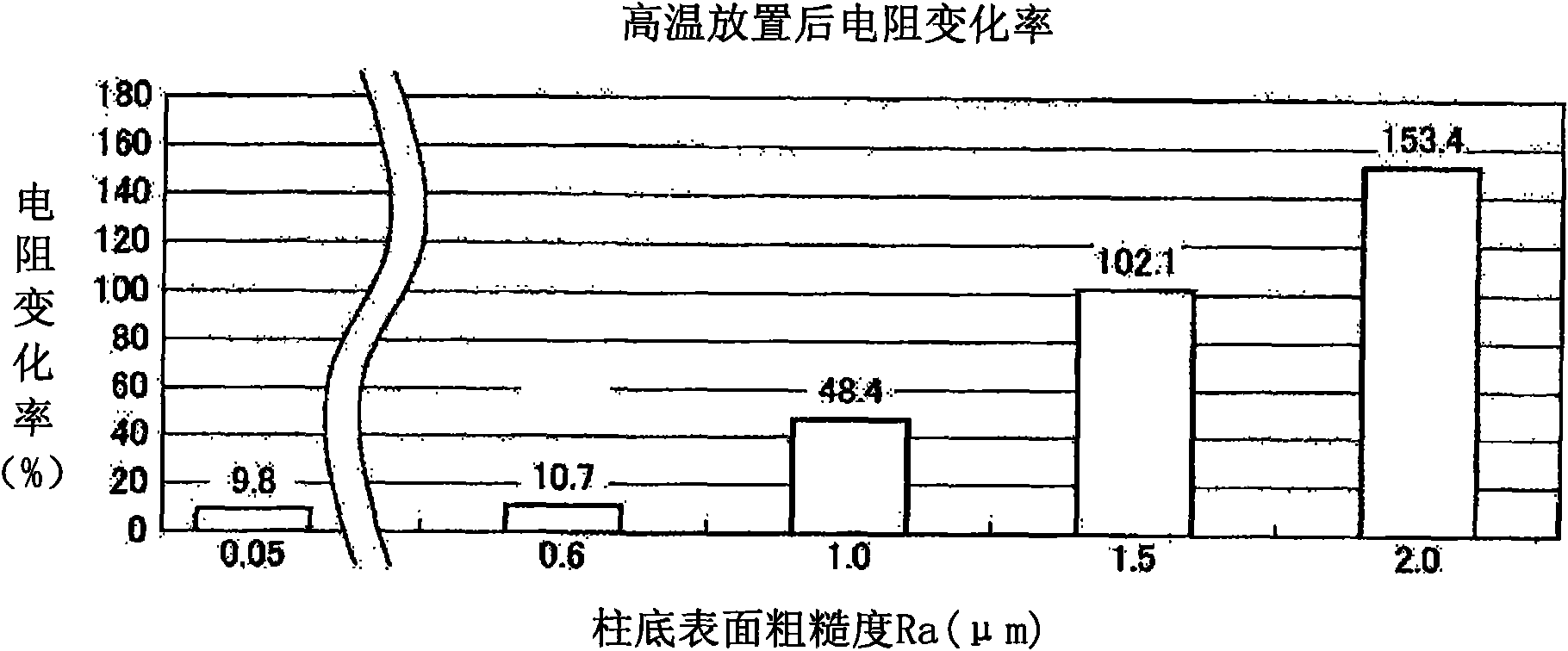

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com