Method for testing electrical conductivity of powdered material

A powder material and electrical conductivity technology, which is applied in the field of testing material properties, can solve the problems of complex data calculation and high operator requirements, and achieve the effects of simple test operation, simple test data processing and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

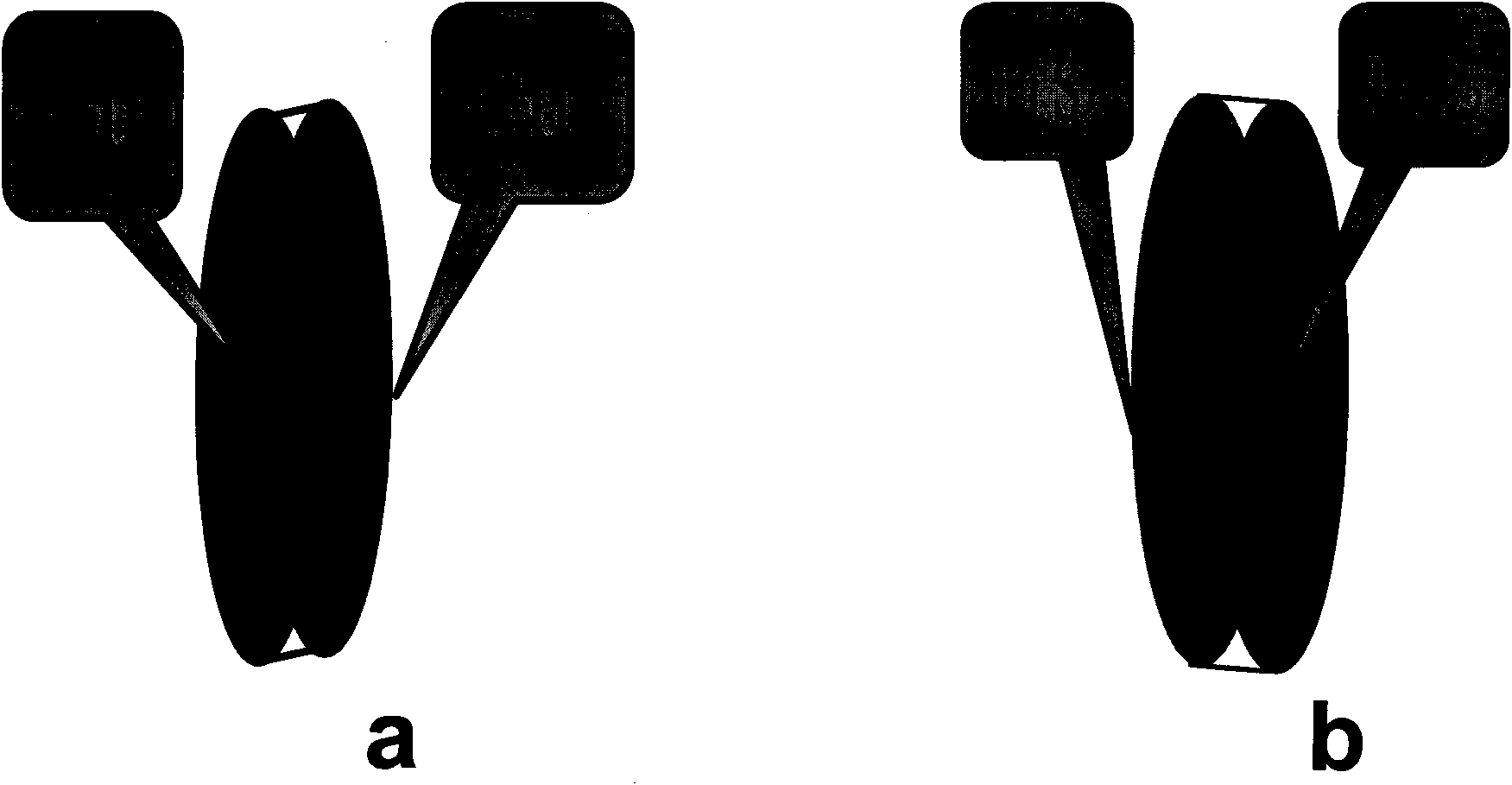

[0032] a. Pressed disc

[0033] Two equal weights of dry lithium manganate powder were sieved through a 200-mesh sieve, and pre-compressed at 1 MPa in a tablet press (Tianjin Keqi, 769YP-40C powder tablet press). Sprinkle copper powder on both sides of one molded sheet through a 200-mesh screen, and sprinkle titanium disulfide powder on both sides of the other molded sheet through a 200-mesh screen, then pressurize to 5 MPa and maintain for 10 minutes to form the disc. Carry out vacuum packaging on a vacuum packaging machine, place the packaged wafers in an isostatic pressing mold, pressurize to 200MPa, and keep for 10 minutes to completely compact the wafers, and finally make the density of the pressed wafers close to that of lithium manganate material the true density of .

[0034] Test the thickness D of the disc, and the radius r of the disc, and calculate the area S of the disc.

[0035] b. DC shunt test

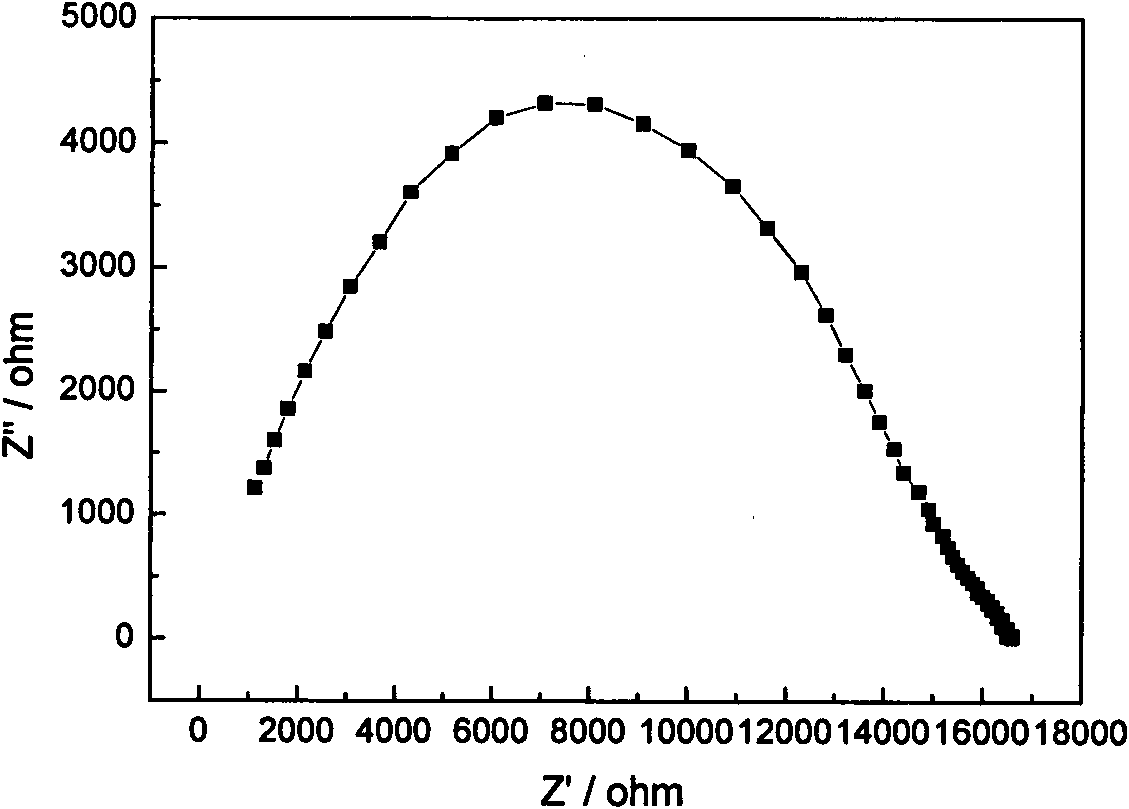

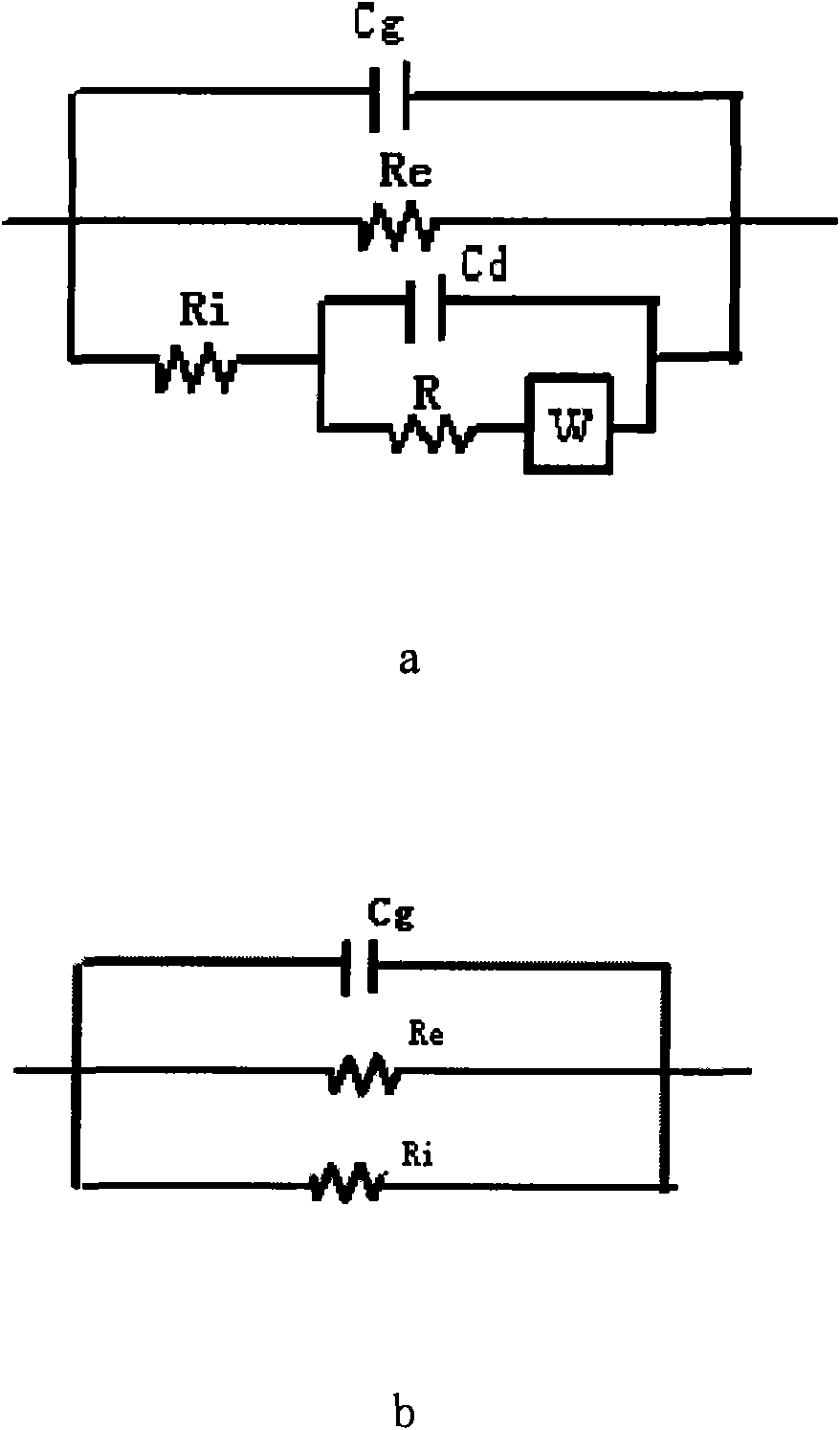

[0036] Connect the wafers coated with copper powder on both sid...

Embodiment 2

[0044] The test method is the same as that of Example 1, the difference is that only the powder material is replaced by lithium cobalt oxide, and the metal powder on both sides of the disk is replaced by silver powder, and the electronic conductivity of the lithium cobalt oxide powder material is finally calculated by testing. The ratio, ionic conductivity and diffusion coefficient are listed in Table 1.

Embodiment 3

[0046] The test method is the same as in Example 1, the difference is that only the powder material is replaced with graphite, and the electronic conductivity, ion conductivity and diffusion coefficient of the lithium cobalt oxide powder material are finally calculated in Table 1.

[0047] Table 1 embodiment test result

[0048] Powder material

[0049] From the test results in table 1, it can be seen that the electronic conductivity, ion conductivity and diffusion coefficient of different powder materials can be tested quickly, simply and easily by adopting the method of the present invention, and then provide research personnel with the powder material Further research on application provides a strong basis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com