Method for producing pasty unclassified tailing filling materials containing red mud

A technology of full tailings and red mud, which is applied in the field of environmental protection engineering and mining engineering, can solve the problems of high mining cost and environmental hazards of cemented filling, and achieve the effects of improving the recovery rate of resource mining, reducing economic pressure, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Dry the red mud to a moisture content of 0.7%, and then grind it to a specific surface area of 800m 2 / kg.

[0018] (2) Dry the blast furnace slag to a moisture content of 0.6%, and then grind it to a specific surface area of 420m 2 / kg.

[0019] (3) Dry the desulfurized gypsum to a moisture content of 0.8%, and then grind it to a specific surface area of 420m 2 / kg.

[0020] (4) Grind the cement clinker until the specific surface area is 350m 2 / kg.

[0021] (5) Mix 24% of the above-mentioned red mud finely ground powder, 56% of water-quenched blast furnace slag finely ground powder, 10% of desulfurized gypsum, and 10% of cement clinker in a mixer according to the percentage by weight on a dry basis. gelling material A.

[0022] (6) Carry out water content detection with whole tailings, and convert its water content into water content according to its adding total amount, be 0.18 by cementitious material A / full tailings weight ratio, water / cementitious ...

Embodiment 2

[0027] Dry the red mud to a moisture content of 0.9%, dry the water-quenched blast furnace slag to a moisture content of 0.4%, and dry the desulfurized gypsum to a moisture content of 0.6%, and then separately grind the water-quenched blast furnace slag to a specific surface area of 400m 2 / kg, the slag powder is mixed with dry red mud, desulfurized gypsum, and cement clinker in a ball mill at 56%, 24%, 11%, and 9% by weight percentage on a dry basis to a specific surface area of 407m 2 / kg to produce gelling material B.

[0028] Check the water content of the whole tailings, and convert the water content into water content according to the total amount of the tailings added. The weight ratio of cementitious material B / full tailings is 0.11, and the weight ratio of water / cementation material is 2.24. Stir evenly A paste full tailings cemented filling material is prepared.

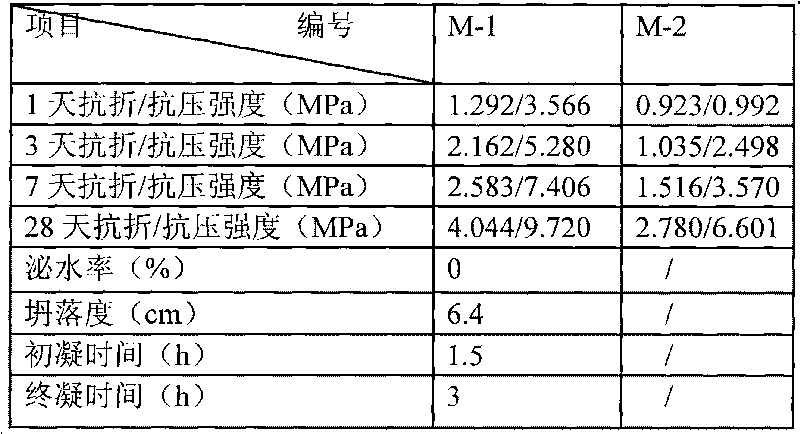

[0029] The paste full tailings filling material prepared according to the above steps has the perfo...

Embodiment 3

[0033] (1) Dry the red mud to a moisture content of 0.8%, and grind it to a specific surface area of 800m 2 / kg.

[0034] (2) Dry the water-quenched blast furnace slag to a moisture content of 0.3%, and grind it to a specific surface area of 420m 2 / kg.

[0035] (3) Dry the desulfurized gypsum to a moisture content of 0.9%, and grind it to a specific surface area of 420m2 / kg.

[0036] (4) Grind the cement clinker until the specific surface area is 350m 2 / kg.

[0037] (5) 50% of the above-mentioned ground red mud powder, 30% of the ground powder of water-quenched blast furnace slag, 9% of desulfurized gypsum, and 11% of cement clinker were uniformly mixed in a mixer according to the percentage by weight on a dry basis. gelling material A.

[0038] (6) Carry out moisture content detection with whole tailings, and convert its moisture content into water content by its added total amount, be 0.18 by cementitious material A / full tailings weight ratio, water / cementitiou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com