Antibacterial pulp mould packing product

A technology for packaging products and pulp molds, applied in the field of pulp molding products, can solve the problems of contamination of the packaged material, easy occurrence of mildew, rot, etc., and achieve the effect of prolonging the life of the goods and improving the quality of the products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Refers to the wild Sophora sophora plant to be collected, including its stems, stems, leaves and seeds (that is, the ground growing part of the wild Sophora sophora plant, without picking the root, which will cause secondary ecological damage to the growing area of the wild Sophora sophora), not Put it in a ventilated and cool place with soil, dry it, and then crush it to ≥50 mesh to make aphora plant fiber for future use.

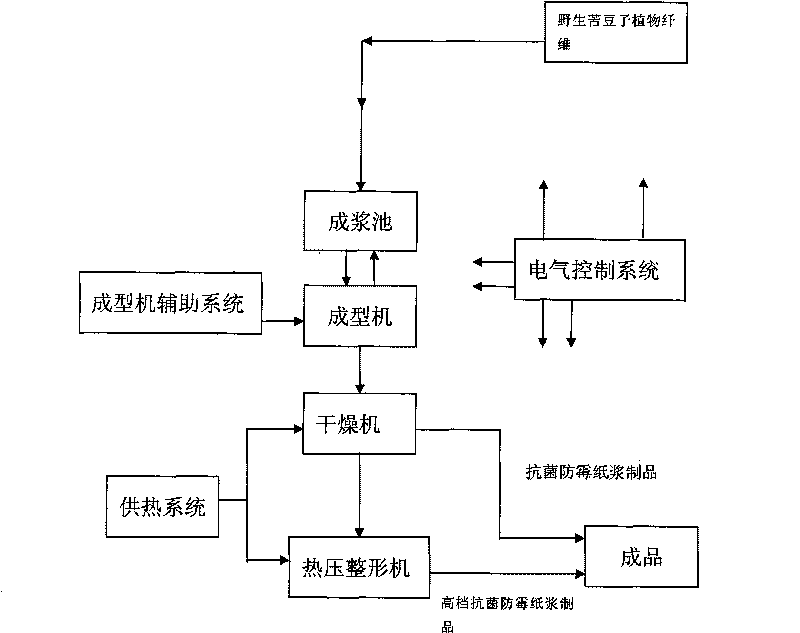

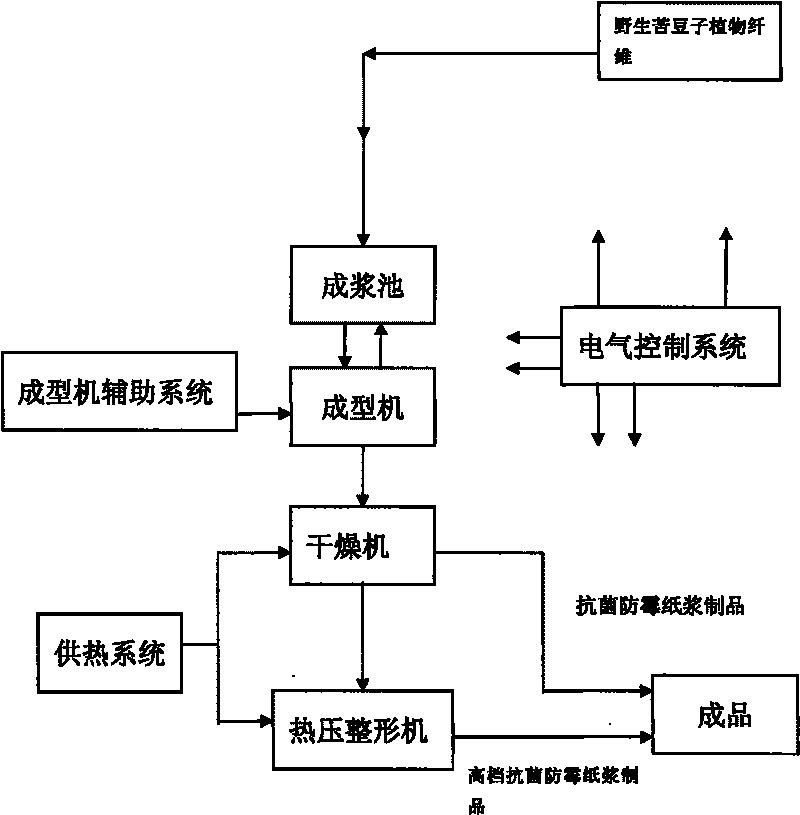

[0016] The production of conventional pulp molded products includes: pulping, sedimentation separation, molding, drying, and hot pressing shaping into finished products. The process of the present invention is the same as the production process of pulp molded products in the prior art. The improvement point is: for the pulping required for the production of pulp molded products, first in the pulping, according to the ratio of 5%-1%: 95%-99%. Ratio Fully mix the fiber pulp of the natural plant Sophora sophora into a new pulp. Then adjust the new s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com