High-efficiency energy-saving plate heat exchange furnace

A high-efficiency energy-saving, plate-type heat exchange technology, applied in the field of boilers, can solve the problems of small heating surface, slow boiler water flow, inconvenient transportation and installation, etc., to achieve increased interaction time, extended water heat exchange path, and good energy-saving effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

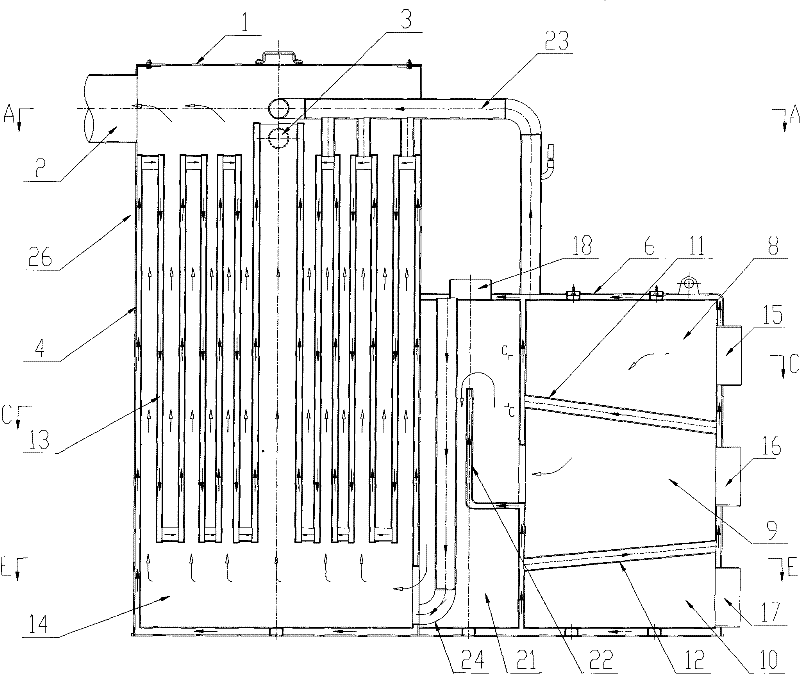

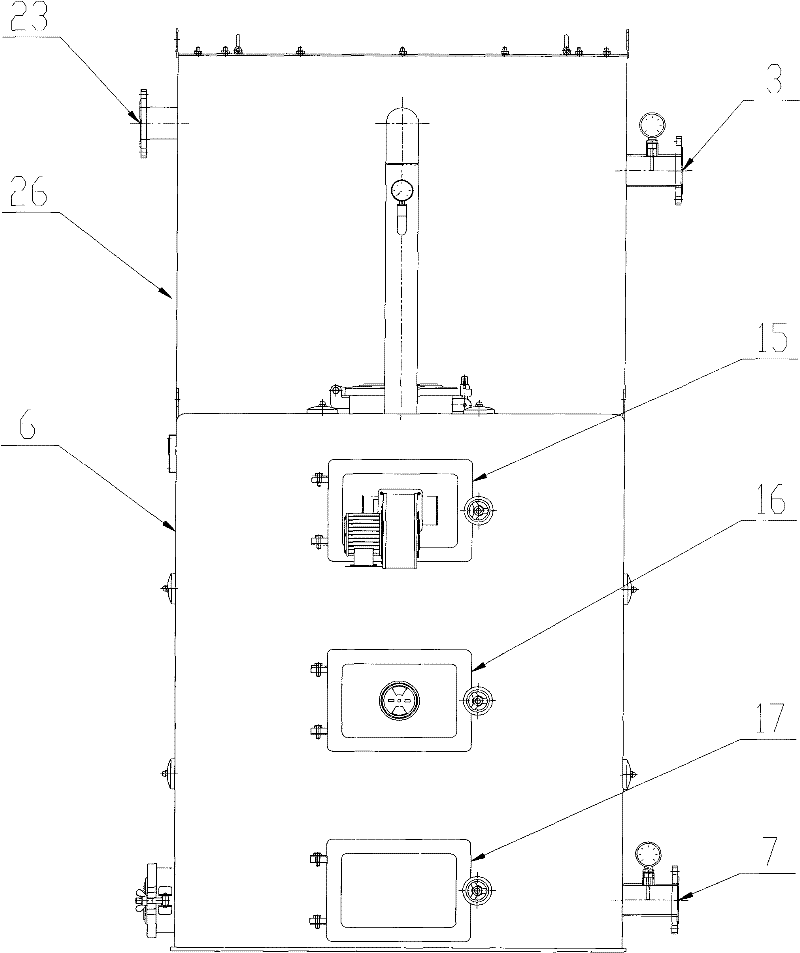

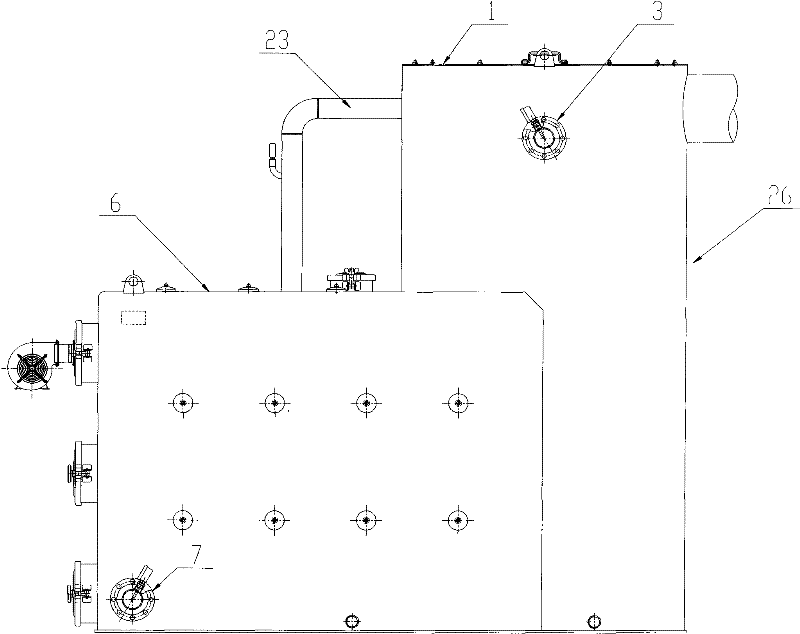

[0027] The present invention will be further described below using the drawings and examples.

[0028] refer to Figure 1-4 , the plate type heat exchange high-efficiency energy-saving furnace of the present invention includes a water jacket furnace body 6 and a water jacket outer cylinder 4, and a feed combustion chamber 8, a combustion chamber 8 and a slag removal chamber are sequentially arranged in the water jacket furnace body 6 from top to bottom 10. A feed combustion chamber furnace door 15 is provided on the water jacket furnace body 6 where the feed combustion chamber 8 is located, and a combustion chamber furnace door 16 is provided on the water jacket furnace body 6 where the combustion chamber 9 is located. The water jacket furnace body 6 where the chamber 10 is located is provided with a slag removal door 17 . The water jacket furnace body 6 between the feed combustion chamber 8 and the combustion chamber 9 is provided with a feed combustion chamber water tube g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com