Pressure type vacuum panel solar thermal collector

A flat-panel solar energy and heat collector technology, applied in the field of solar energy applications, can solve problems such as not being able to operate around the clock, and achieve the effects of preventing pressure cracks, efficiently producing hot water, and enhancing pressure-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

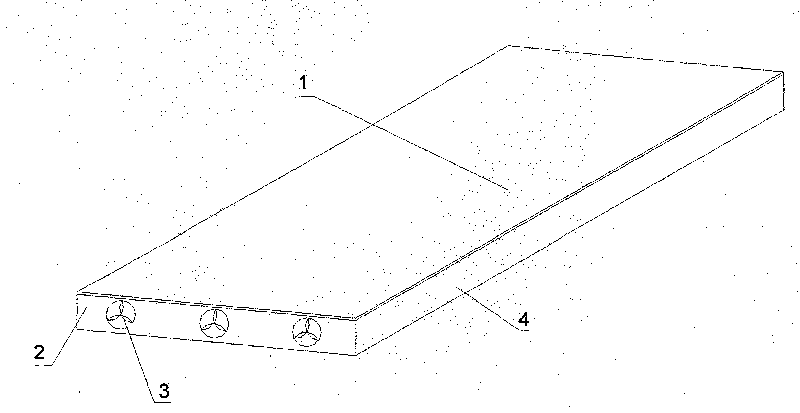

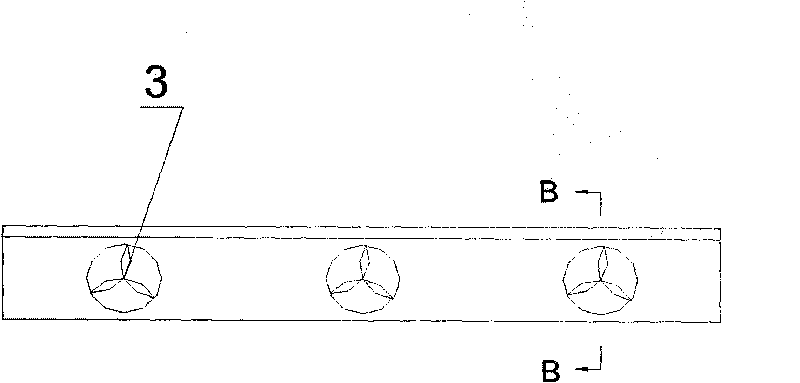

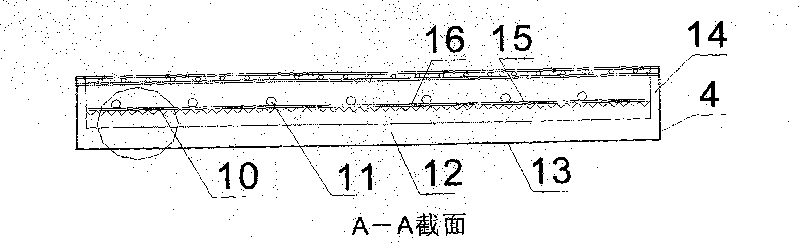

[0025] The pressure-bearing vacuum flat solar collector 18 of the present invention is mainly composed of a glass cover plate 1, an end baffle plate 2, a bottom plate 13, a perfusion fan 3, a side baffle plate 4, a check air valve 6, a bottom insulation layer 12, and a side insulation layer. 14. The heat collecting plate 15, the heat transfer tube 11, the aluminum tube strip 10, and the heat transfer fin 16 are composed. Glass cover plate 1 is made of upper glass cover plate 8, lower glass cover plate 9, bead 7 and sealing strip 5 around. There are several heat pump working fluid passages 17 on the aluminum pipe strip 10 .

[0026] The heat loss of the vacuum flat plate collector is mainly concentrated in the heat transfer to the surrounding air through the vacuum glass cover plate 1 . In order to reduce heat transfer. The main measure in this design is to evacuate between the two glass plates, which reduces the heat loss of the heat collecting plate 15 to the environment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com