Method for measuring large deformation flow stress curve of metal plate

A technology of sheet metal and flow stress, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve problems such as irregularities, numerous models, and numerical simulations that cannot accurately describe the forming process and its phenomena, so as to ensure accurate performance, the effect of extending the test range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

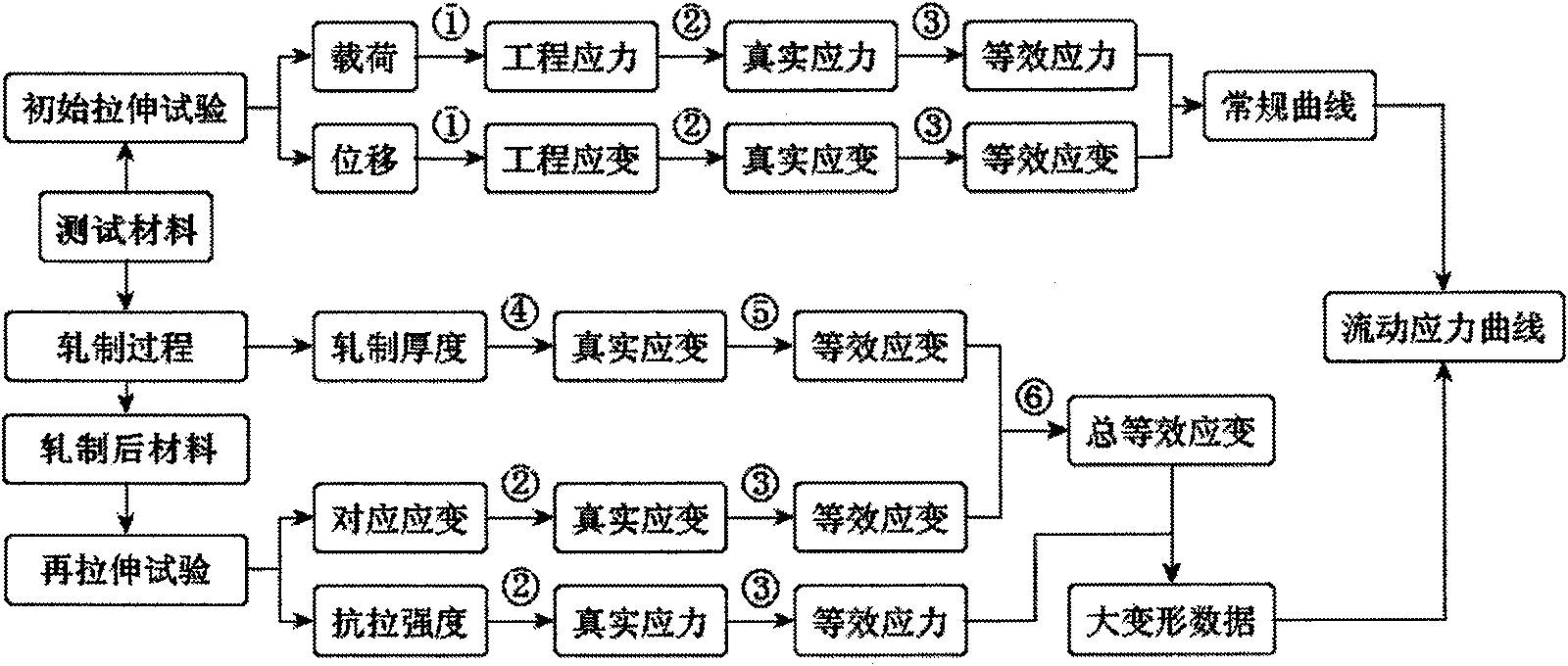

[0022] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation methods and processes are given, but the protection scope of the present invention is not limited to the following embodiments.

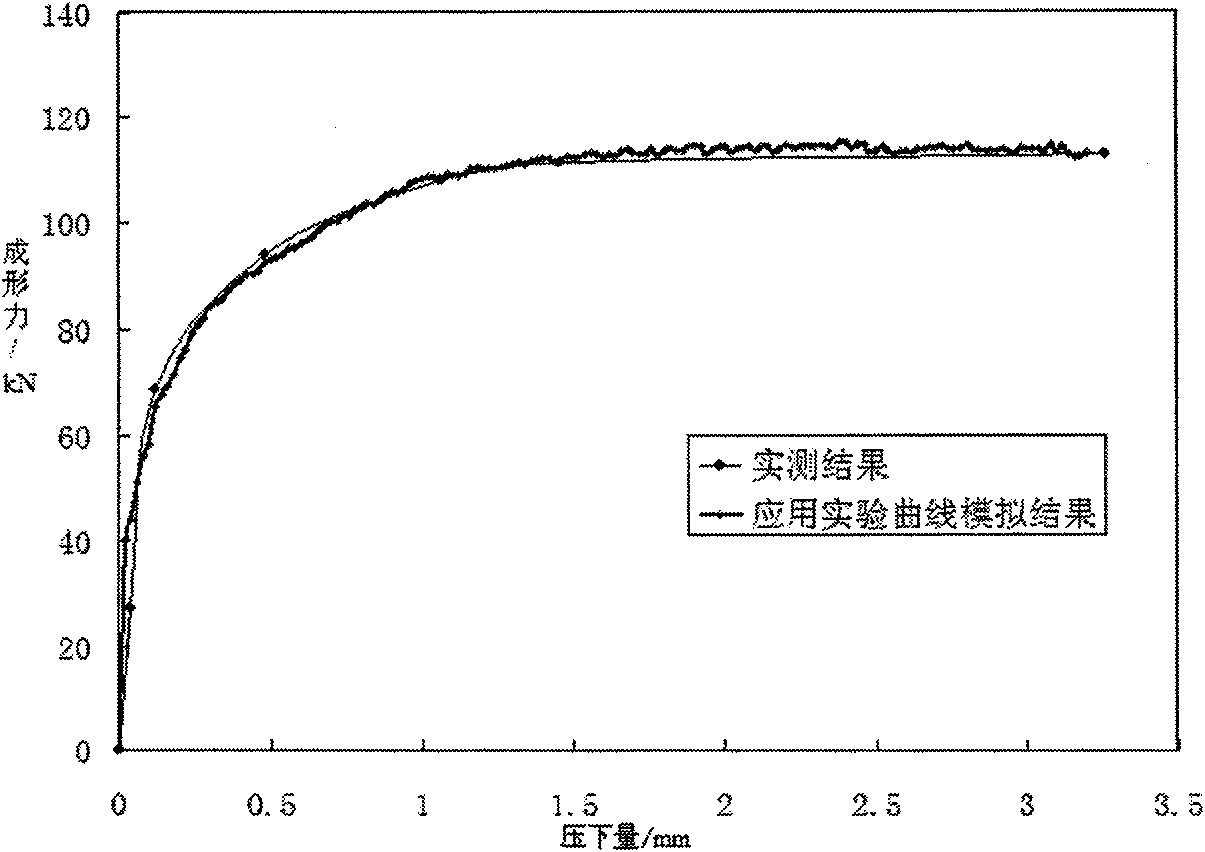

[0023] like figure 1 shown. The concrete conversion of this embodiment is as follows:

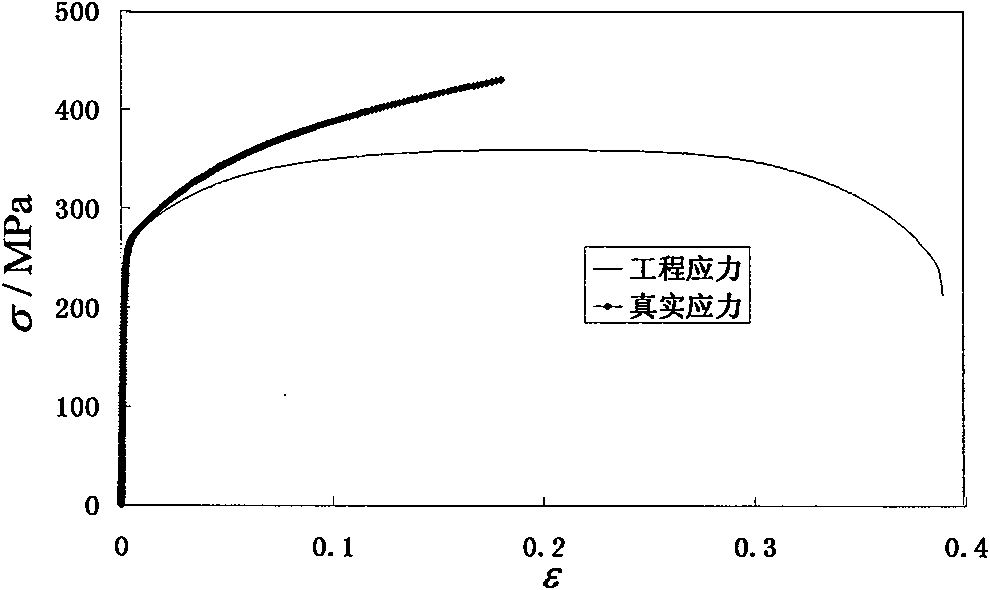

[0024] ① In the tensile test, load-displacement conversion engineering stress-strain: σ E = P A 0 , ϵ E = ΔL L 0 , where σ E is the engineering stress, e E is engineering strain, P is load, A 0 is the original area of the material, ΔL is the length change measured by the strain extensometer, L 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com