Thermostatic control method and thermostatic control device for photodiode

A photodiode and constant temperature control technology, which is applied in temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of circuit complexity and precision, and achieve the effect of precise temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

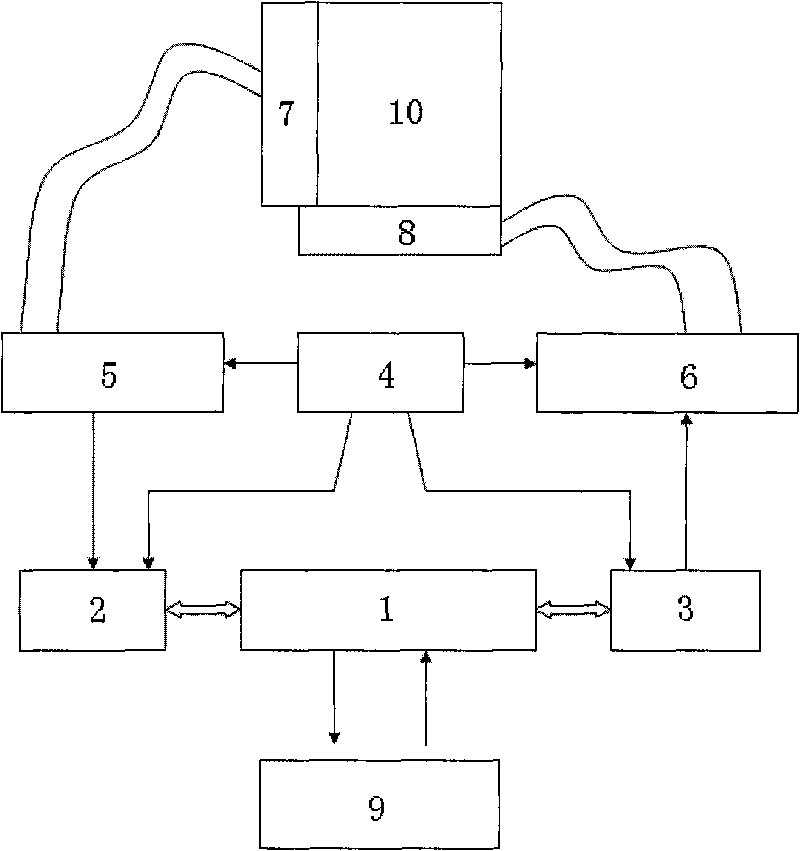

[0018] figure 1 Instructions marked in: 1-digital signal processor, 2-analog-to-digital converter, 3-digital-to-analog converter, 4-reference voltage source, 5-temperature signal processing circuit, 6-pulse width modulation power drive circuit, 7- Temperature sensor, 8-semiconductor refrigerator, 9-RS232 serial interface circuit, 10-photodiode fixture.

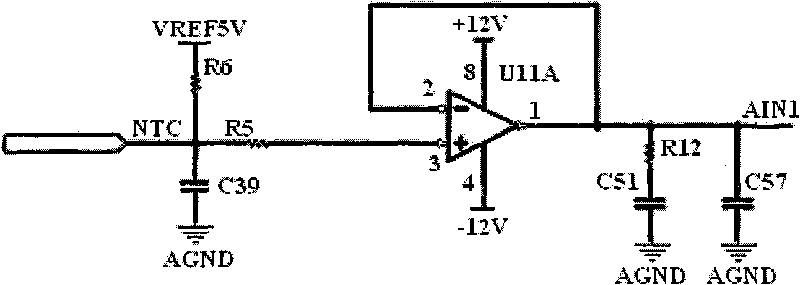

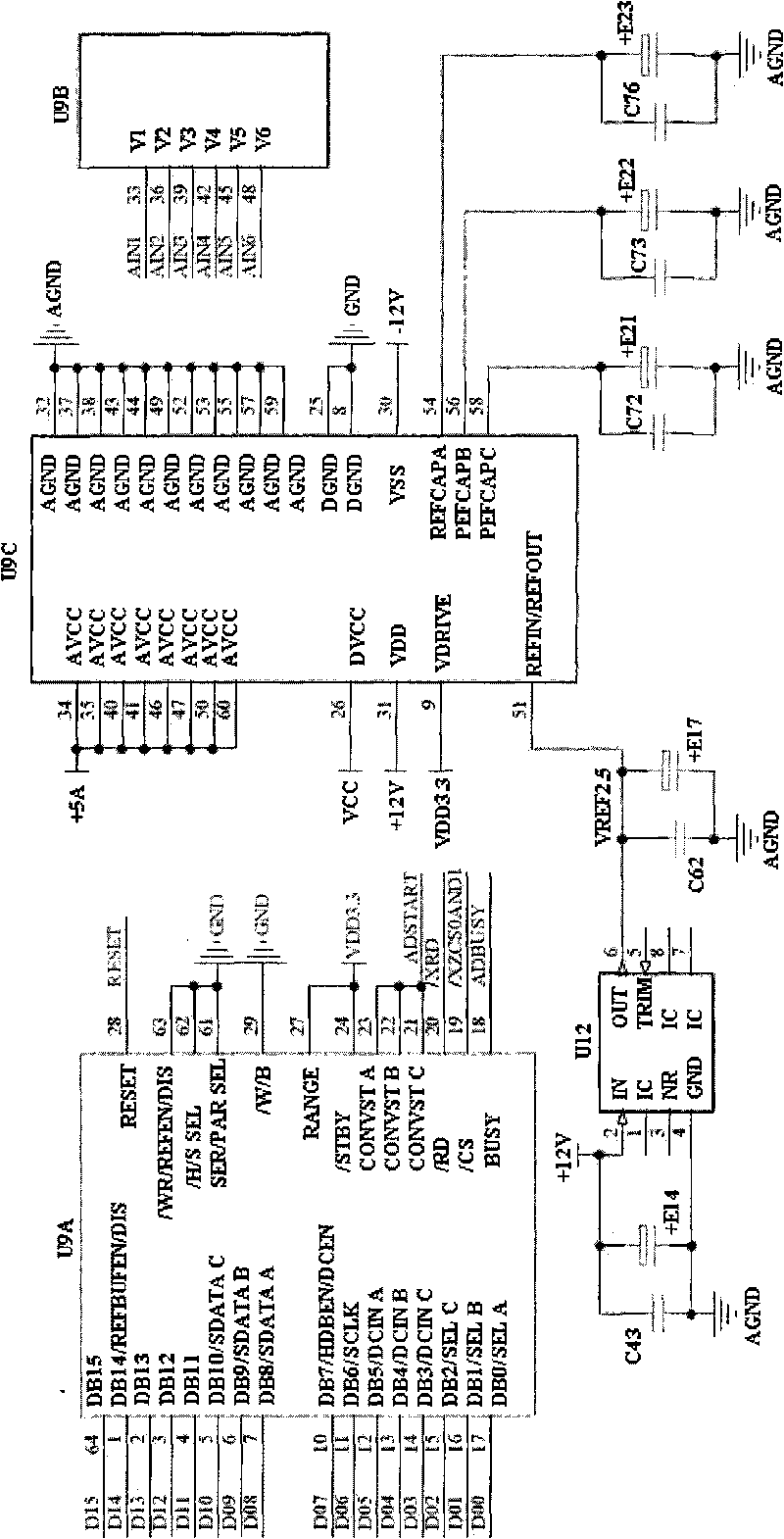

[0019] Such as figure 1 As shown, the device according to the embodiment of the present invention includes two parts: a photodiode fixture and a temperature control card, and the fixture part and the temperature control card are connected by flexible wires. The photodiode fixture part includes a photodiode fixture 10, a temperature sensor 7 and a semiconductor refrigerator 8; the temperature control card part includes a digital signal processor 1, an analog-to-digital converter 2, a digital-to-analog ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com