Wastewater pretreatment method

A technology of pretreatment and wastewater, applied in water/sewage multi-stage treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of impossible biochemical treatment, and achieve improved biodegradability and COD reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

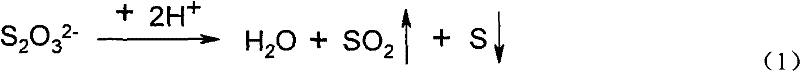

Problems solved by technology

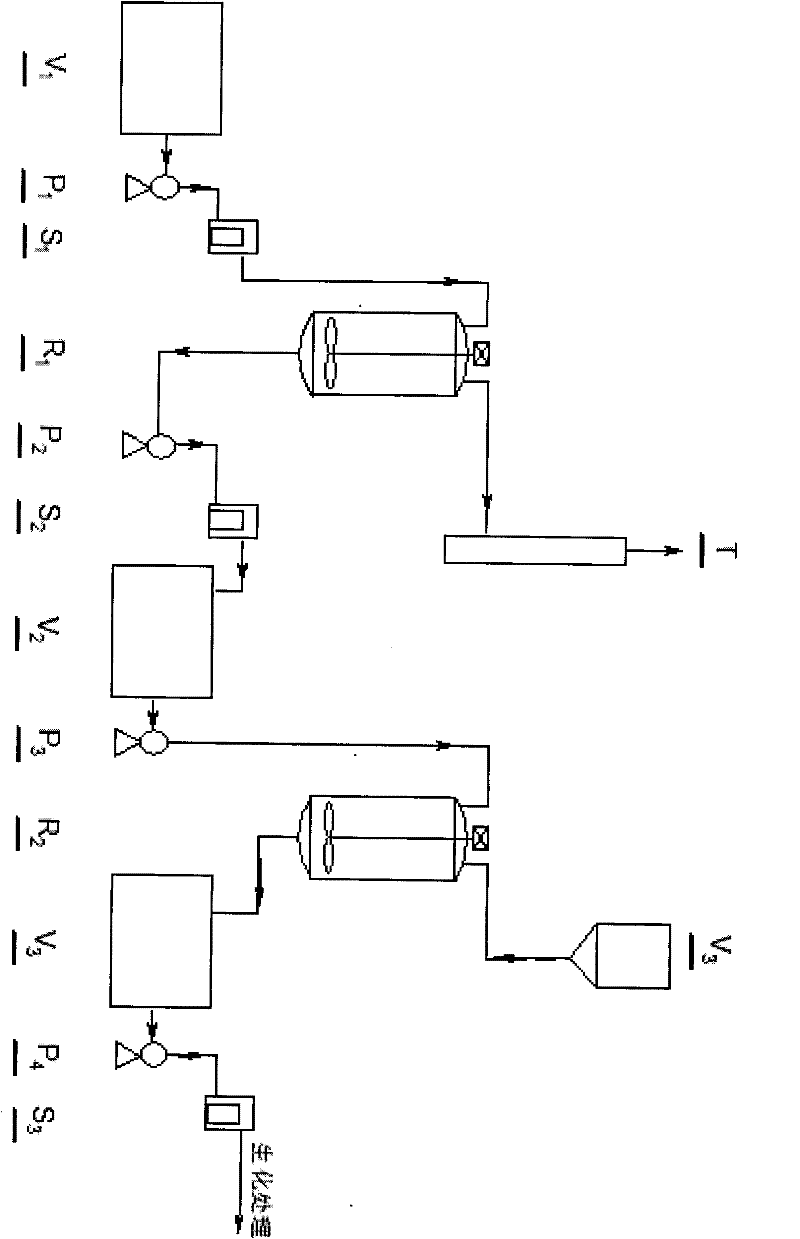

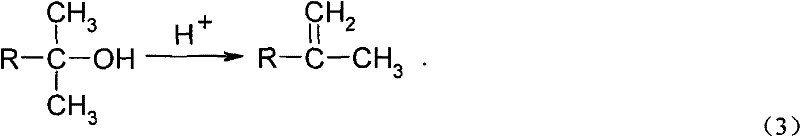

Method used

Image

Examples

Embodiment 1

[0051] Use sulfuric acid to adjust the pH of 1,000 grams of reduced wastewater with a COD of 68,900 mg / L to 6.2, then add 20 grams of sulfuric acid, raise the temperature to 100°C, and react for 4 hours. The gas generated by the reaction is absorbed with lye. After the reaction, the waste water was cooled to room temperature, the solid in the waste water was filtered off, and the oil layer was skimmed off. The COD of the water layer was 21400mg / L. The water layer enters the Fenton reactor, and 0.2 g of FeSO is added 4 , 4 grams of 27% H 2 o 2 Stir and react at 50°C for 4 hours. The COD of the effluent is 12900mg / L, the COD removal rate is above 80%, the B / C is greater than 0.3, and the COD of the effluent can be below 100mg / L after biochemical treatment.

Embodiment 2

[0053] Use hydrochloric acid to adjust the pH of 1,000 grams of reduced wastewater with a COD of 68,900 mg / L to 5.3, then add 10 grams of concentrated hydrochloric acid, raise the temperature to 95°C, and react for 4 hours. The gas generated by the reaction is absorbed with lye. After the reaction finished, the waste water was cooled to room temperature, the solid in the waste water was filtered, and the oil layer was skimmed off, and the COD of the water layer was 22700mg / L. The water layer enters the Fenton reactor, and 0.2 g of FeSO is added 4 , 4 grams of 27% H 2 o 2 Stir and react at 50°C for 4 hours. The effluent COD is 12100mg / L, the COD removal rate is above 80%, and the B / C is greater than 0.3.

Embodiment 3

[0055] Use nitric acid to adjust the pH of 1,000 grams of reduced wastewater with a COD of 68,900 mg / L to 6.5, then add 15 grams of nitric acid, raise the temperature to 98°C, and react for 4 hours. The gas generated by the reaction is absorbed with lye. After the reaction, the waste water was cooled to room temperature, the solid in the waste water was filtered off, and the oil layer was skimmed off. The COD of the water layer was 23100mg / L. The water layer enters the Fenton reactor, and 0.2 g of FeSO is added 4 , 4 grams of 27% H 2 o 2 Stir and react at 50°C for 4 hours. The effluent COD is 12500mg / L, the COD removal rate is above 80%, and the B / C is greater than 0.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com