On-line failure diagnosis, prediction and feedback control method of small/medium size gas turbine and device thereof

A technology of gas turbine and feedback control, which is applied in the fields of prediction, feedback control, and online fault diagnosis of medium/small gas turbines. The ability to prevent unexpected failures and the effect of improving the operation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

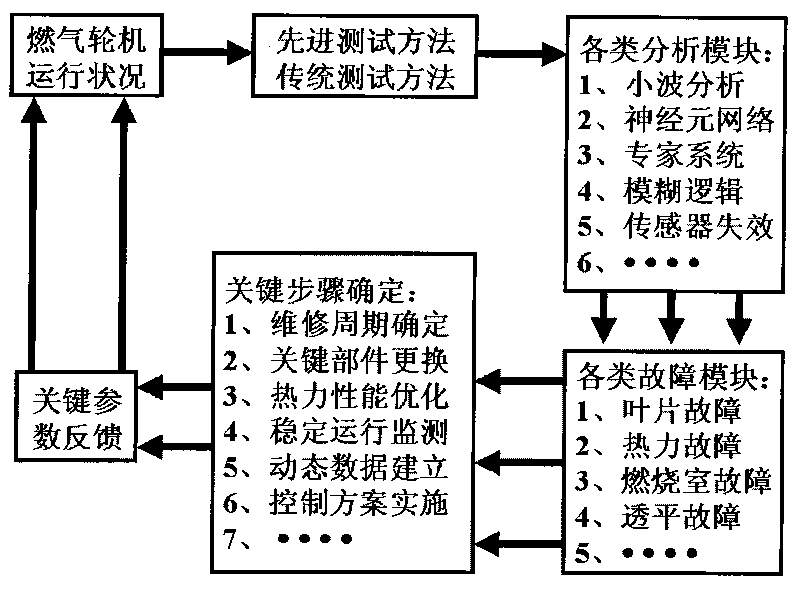

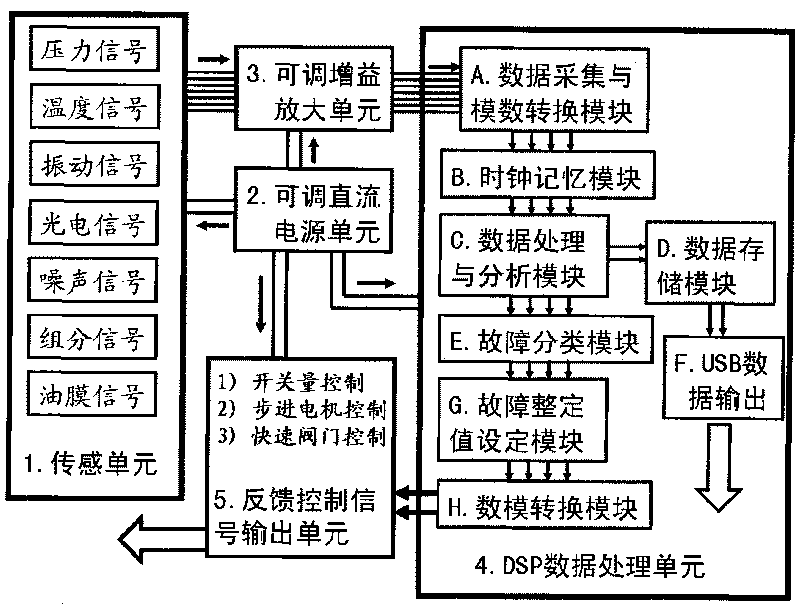

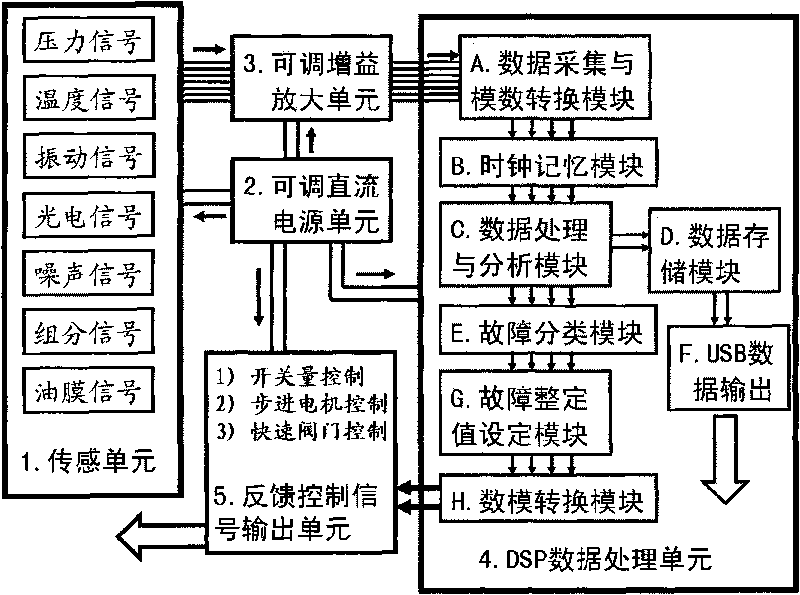

[0010] The following is based on figure 1 and figure 2 , a preferred embodiment of the present invention is given and described in detail, so that the functions and features of the present invention can be better understood.

[0011] The technical scheme of the present invention is based on DSP technology. according to figure 1 As shown, the function description of each module is as follows:

[0012] a) The design state or non-design state of gas turbine operation is mainly determined by output power or thrust, combustion chamber outlet temperature, compressor inlet pressure and flow, turbine front temperature, unit speed, guide / stator vane installation angle, pollutant emission components , Rotor vibration frequency / amplitude, noise distribution characteristics and other parameters are displayed.

[0013] b) The testing of failure analysis The primary instruments and sensors are based on the system combining advanced testing technology and traditional testing technology,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com