Gas-solid phase in-situ Raman reaction tank

An in-situ reaction, gas-solid phase technology, applied in Raman scattering, material excitation analysis, etc., can solve the problems of powder sample filling and cleaning difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

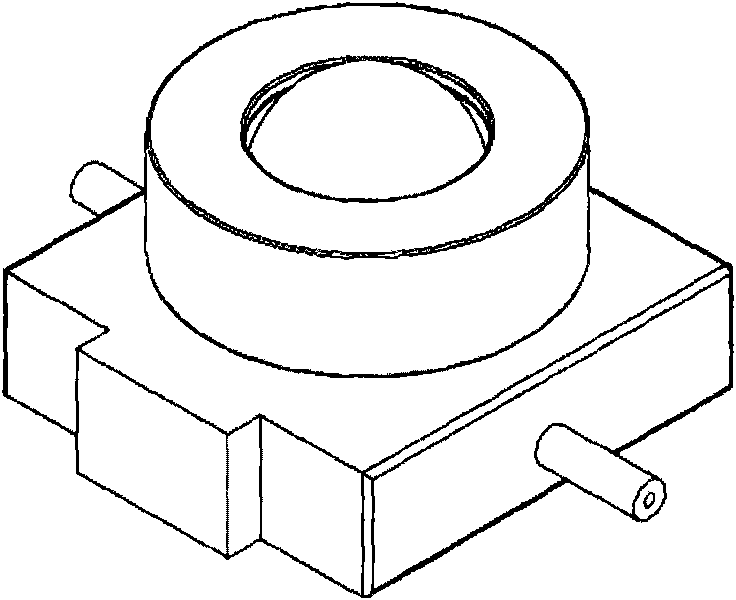

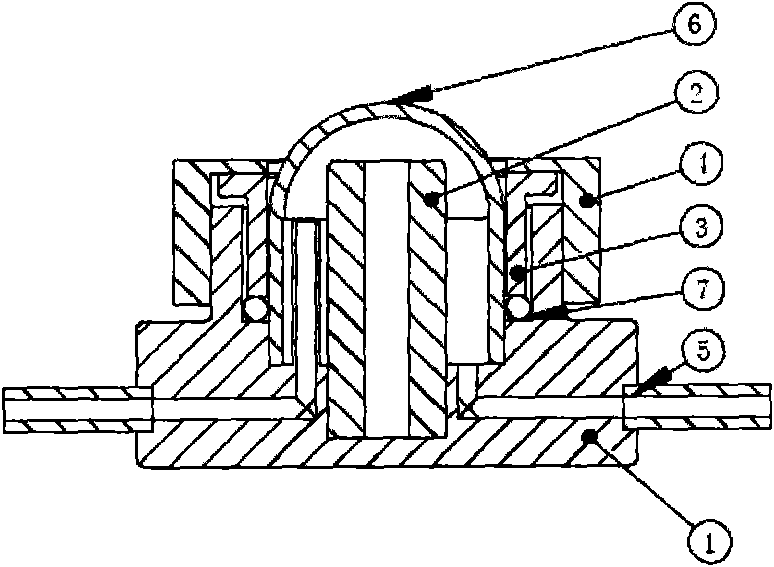

[0013] In this example, the gas-solid phase Raman in situ reaction cell such as figure 2 and image 3 shown. The material of the base of the in situ pool is stainless steel, and the size of the base is 34×34×18mm. The detachable sample cell has an outer diameter of 4mm, an inner diameter of 1.5mm, a length of 20mm, and an outer thread length of 10mm. It is made of stainless steel. The outer diameter of the fused silica is 8mm, the inner diameter is 14mm, the radius of the bulb part is 6mm, and the total height is 18mm. The outer diameter of the sealing ferrule is 19mm, the inner diameter is 16.2mm, and the height is 8.5mm. The hollow nut has an outer diameter of 29mm, an inner diameter of 24mm, and a knurled outer surface.

[0014] In this example, the commercial carbon black of Printex U from Degussa Company is used as the powder sample. Fill the powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com