Two-side water cooling substrate of power module of current transformer

A power module, water-cooled heat dissipation technology, applied in the direction of output power conversion device, cooling/ventilation/heating transformation, electrical components, etc., can solve the problems of poor heat dissipation effect, complicated manufacturing process, large volume, etc., to improve the heat dissipation effect , Good cooling effect, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

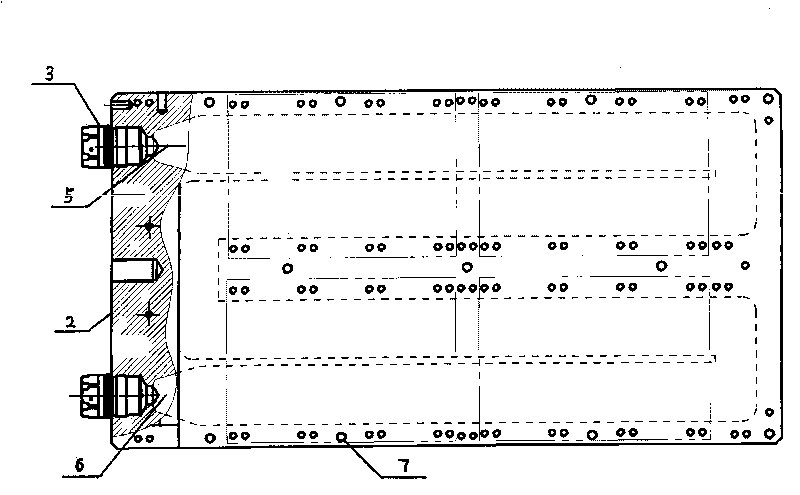

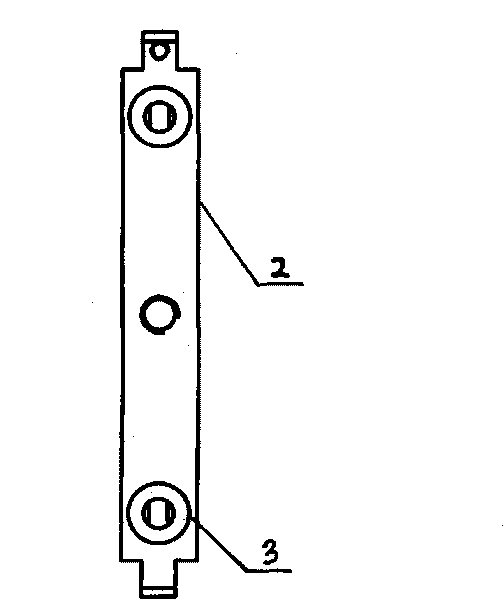

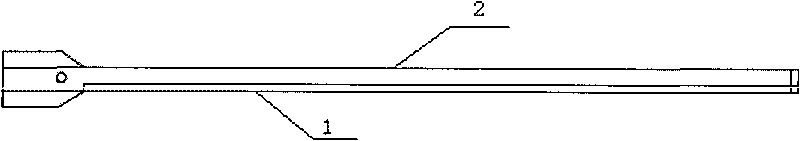

[0017] The double-sided water-cooled heat dissipation substrate of the converter power module includes the heat dissipation substrate brazed by the upper cover plate 1 and the lower base plate 2, and the end surface of the lower base plate 2 is provided with a water inlet 6 and a water outlet 5 connecting the water channel 9 and the external circulating water , there are mounting holes 7 on the outer surfaces of the upper cover 1 and the lower base 2 (according to the usual installation position of power components, the outer surface refers to the upper surface of the upper cover and the lower surface of the lower cover), and the lower base The inner surface of 2 (that is, the mutual contact surface between the lower base plate 2 and the upper cover plate 1) is provided with a groove-shaped water channel 9, and square-wave heat dissipation fins 4 formed by regular bending are placed in the water channel 9.

[0018] The water channel 9 is a water tank processed on the inner surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com