Method for preparing additional hydrolyzing seed crystal

A technology of seed crystal and aqueous solution, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of affecting the dispersion of seed crystals, poor quality of seed crystals, and affecting the quality of seed crystals, and achieves easy control, simple process, and corrosion resistance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

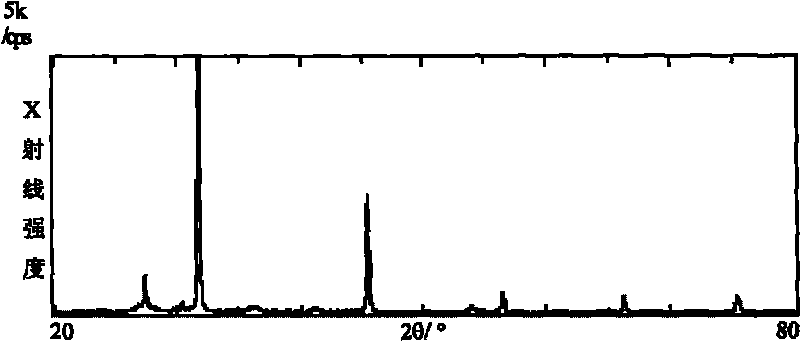

[0047] To 1500mL (milliliters) 3% NaOH solution, add concentration and be 200g / L (as TiO 2 count) TiCl 4 Aqueous solution, the pH value of the system after neutralization is 4.0, while keeping the system temperature not exceeding 60°C. After neutralizing the precipitate and filtering it, wash it with 255g deionized water, and filter the cake according to TiO 2 The content is 50g / L beating. Add 30% (wt) HCl to the slurry at a mass ratio of acid to titanium of 0.9:1, stir thoroughly and then raise the temperature to 70°C at a rate of 1.0°C / min, and keep it warm for 30min. To this was added 500 mL of deionized water while stirring. Finally, use 3% NaOH solution to adjust the pH value of the system to 3.0, keep the temperature of the system less than or equal to 50°C, and let the obtained slurry stand for 5 hours, pour the upper clear liquid, and the lower part of the precipitation is the external hydrolysis seed crystal, which is commonly used in this field. Analytical means ...

Embodiment 2

[0050] To 1500mL 10% NH 3 ·H 2 Adding concentration in O is 300g / L (as TiO 2 count) TiCl 4 Aqueous solution, the pH value of the system after neutralization is 4.5, and the temperature of the system shall not exceed 60°C. After neutralizing the precipitate and filtering it, wash it with 850g deionized water, and filter the cake according to TiO 2 The content is 60g / L beating. Add 60% (wt) HNO to the slurry according to the acid-titanium mass ratio of 0.9:1 3 , after fully stirring, the temperature was raised to 75°C at a rate of 2.0°C / min, and kept for 40 minutes. To this was added 825 mL of deionized water while stirring. Finally with 3% NH 3 ·H 2 O solution adjusts the pH value of the system to 6.0, keeps the system temperature less than or equal to 50°C, and puts the obtained slurry for 6 hours, pours the upper clear liquid, and the lower part of the precipitate is the external hydrolysis seed, and its TiO 2 The content is 40g / L.

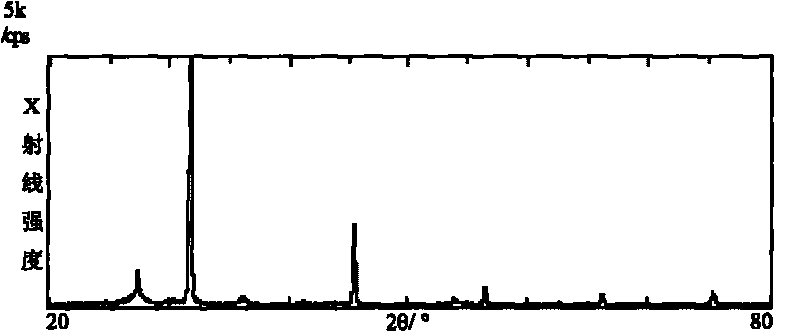

[0051] Through XRD analysis, the...

Embodiment 3

[0053] Add concentration to 1500mL 5% NaOH and be 360g / L (as TiO 2 count) TiCl 4 Aqueous solution, the pH value of the system after neutralization is 5.0, and the temperature of the system is kept less than or equal to 60°C. After neutralizing the precipitate and filtering it, wash it with 1000g deionized water, and filter the cake according to TiO 2 The content is 80g / L beating. Add 35% (wt) HCl to the slurry at a mass ratio of acid to titanium of 0.5:1, stir thoroughly and then raise the temperature to 80°C at a rate of 3.0°C / min, and keep it warm for 30min. 1400 mL of deionized water was added thereto while stirring. Finally, use 5% NaOH solution to adjust the pH value of the system to 5.0, keep the temperature of the system less than or equal to 50°C, and let the obtained slurry stand for 6 hours, pour the upper clear liquid, and the lower part of the precipitate is the external hydrolysis seed, the TiO 2 The content is 45g / L.

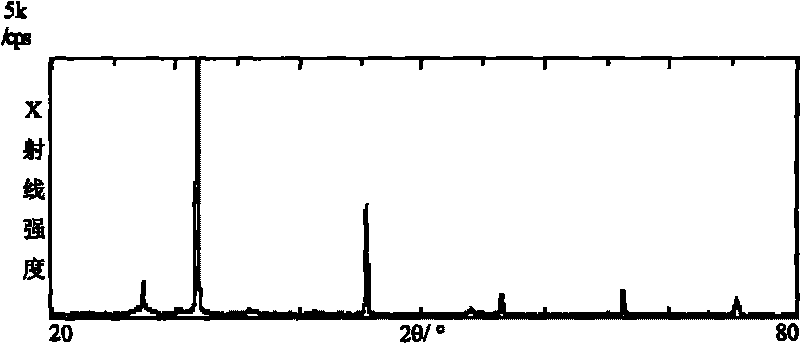

[0054] Through XRD analysis, the rutile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com