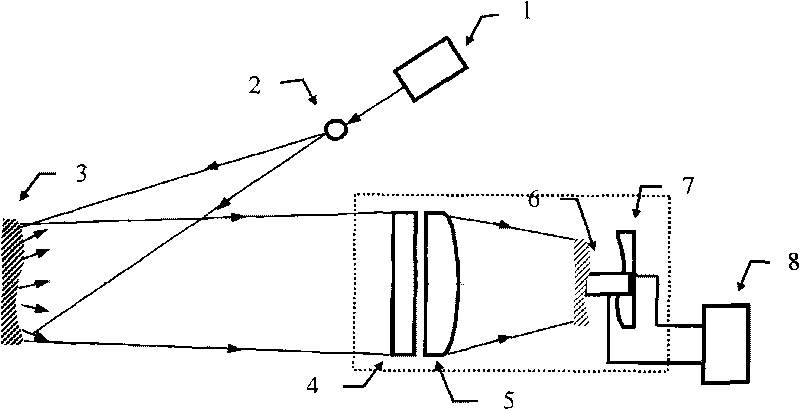

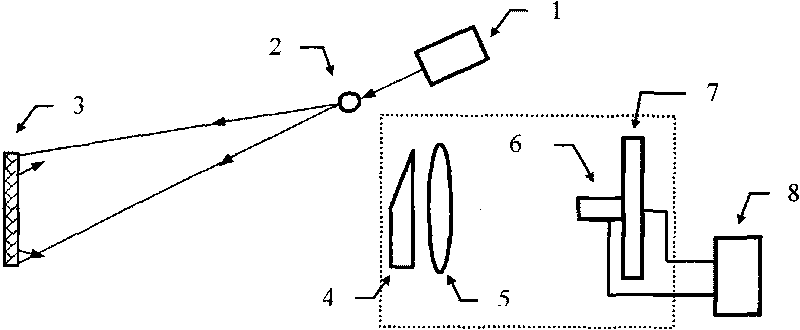

Method of nondestructive testing with digital shearing speckle interferometry and device thereof

A speckle interference and non-destructive testing technology, which is applied in the direction of optical testing flaws/defects, etc., can solve the problem that the sensitivity and resolution of digital shearing speckle interference technology cannot be further improved, and cannot achieve large field of view and high sensitivity at the same time. Focus and other problems, to achieve the effect of increasing the area, improving the sensitivity, and improving the sampling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

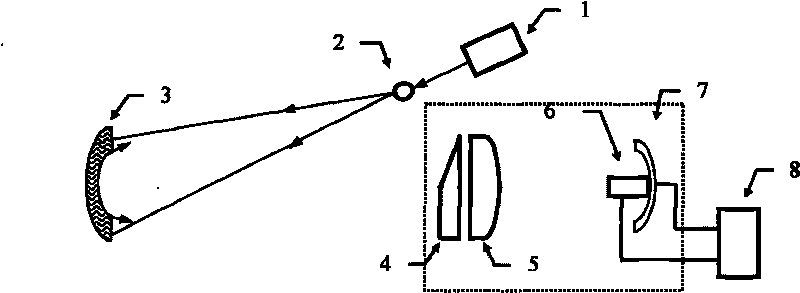

Embodiment 2

[0042] The working mode and process of embodiment 2 are basically the same as embodiment 1, and the difference is that in embodiment 2, the surface of sample 3 is distributed in different planes through cylindrical lens 3 due to the fact that the surface of sample 3 is a non-plane. Therefore, the trajectory of the micro-displacement platform 7 that can be moved in two-dimensional directions is a curve consistent with the fluctuation of the image plane, so that the speckle image in the final synthesized two-dimensional sheared speckle image is clearly in focus.

[0043] The beneficial effect of this embodiment is that when the surface of the sample to be tested has large fluctuations, such as the inner surface of a tire, the moving track of the micro-displacement platform can be designed according to the elliptical shape of the inner surface, so that each image point on the obtained shear speckle pattern Clear in focus; the introduction of the cylindrical lens makes no aberratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com