Electron gun assembly die and assembling method thereof

A technology for electron guns and molds, which is applied in the manufacture of electrical components, electrode assemblies, DC voltage accelerators, etc., can solve problems such as precision and tooling difficulty, and achieve the effects of improving yield, preventing current heating, and ensuring electron optical parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

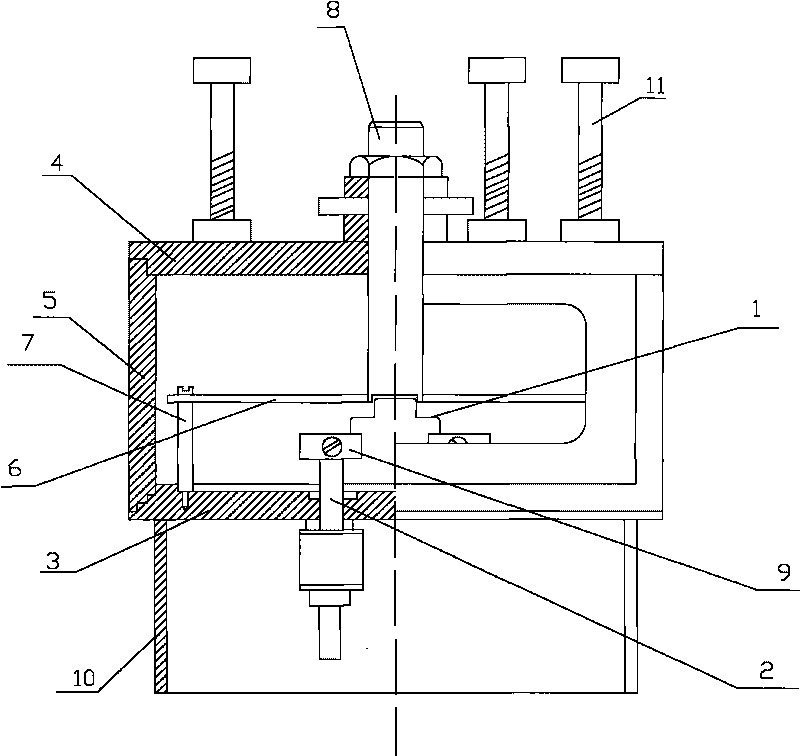

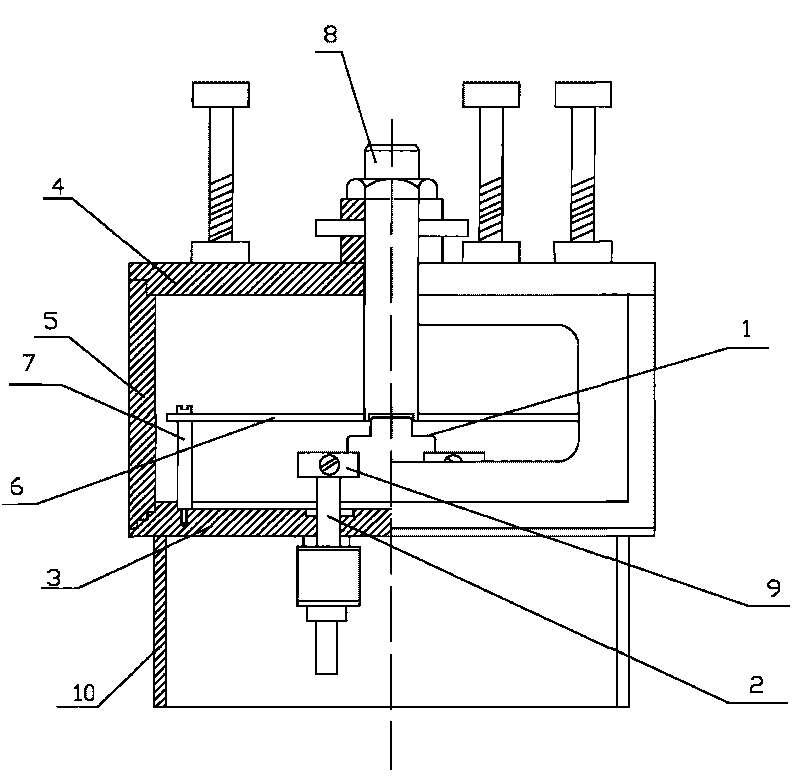

[0020] Below in conjunction with accompanying drawing description, the present invention is described in further detail:

[0021] like figure 1 Shown: an assembly mold for an electron gun, including an upper positioning mold 4, a sleeve mold 5, and a support seat 10. The cover of the upper positioning mold 4 is pressed on the sleeve mold 5, and the support base 10 is placed under the gun cover plate, and the center positioning is also included. 8; the center positioning member 8 is arranged at the center of the upper positioning mold 4, and also includes an upper support 11; the upper support 11 is arranged on the upper positioning mold 4, and the upper support 11 is set thread.

[0022] A method for assembling the described electron gun assembly mold, comprising the following steps:

[0023] 1) After the lead electrode 2 and the gun cover 3 are welded and formed, the gun cover 3 is installed with one end of the non-inductive filament 1 facing upwards and placed on the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com