Composite biomass compression molding device

A compression molding and biomass technology, which is applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problems of low yield and blockage, and achieve low yield, reduce roughness, and reduce equipment energy consumption with the effect of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further described in detail through the following embodiments in conjunction with the accompanying drawings, but the technical content described in this embodiment is illustrative rather than restrictive, and should not limit the protection scope of the present invention accordingly.

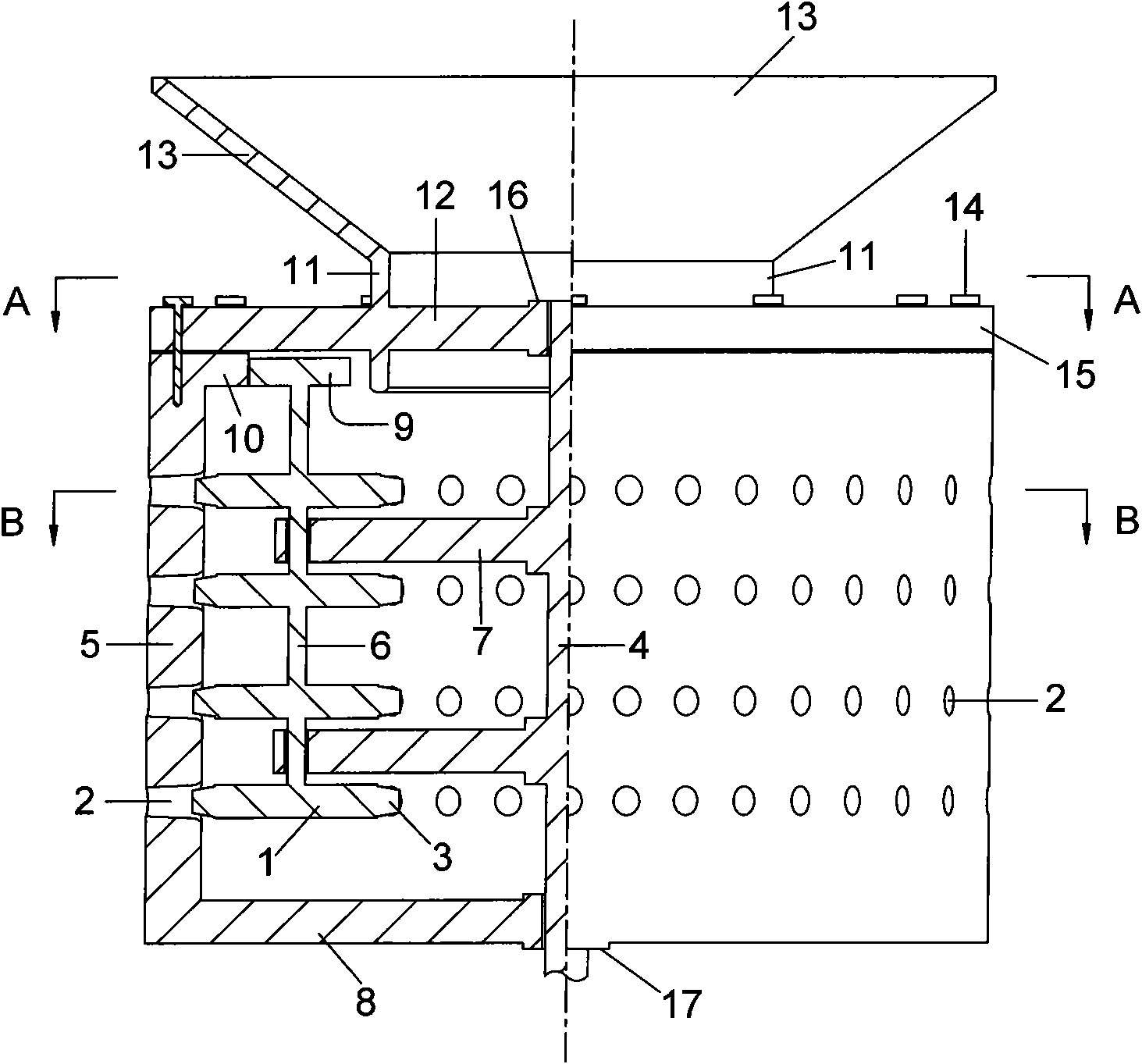

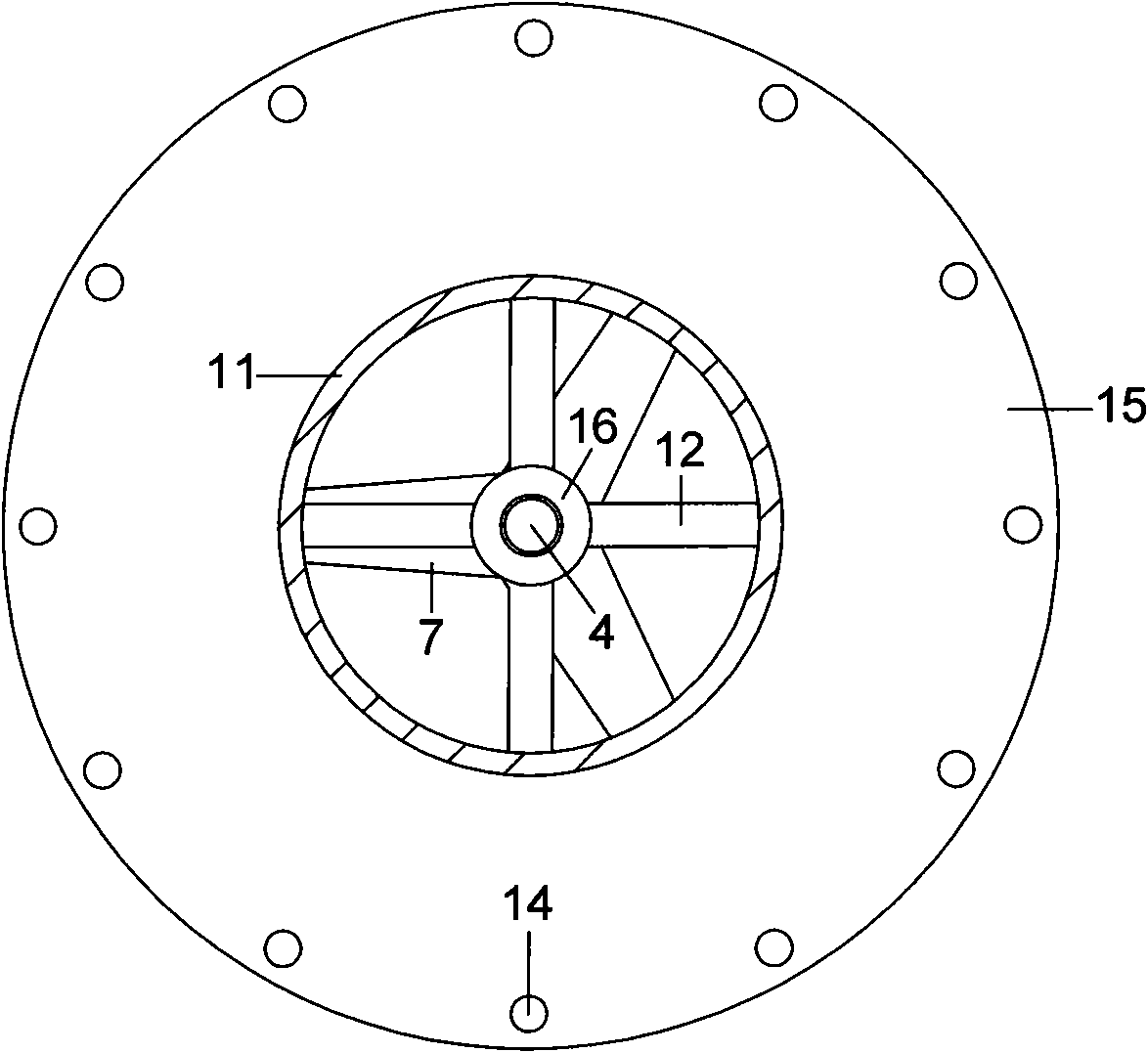

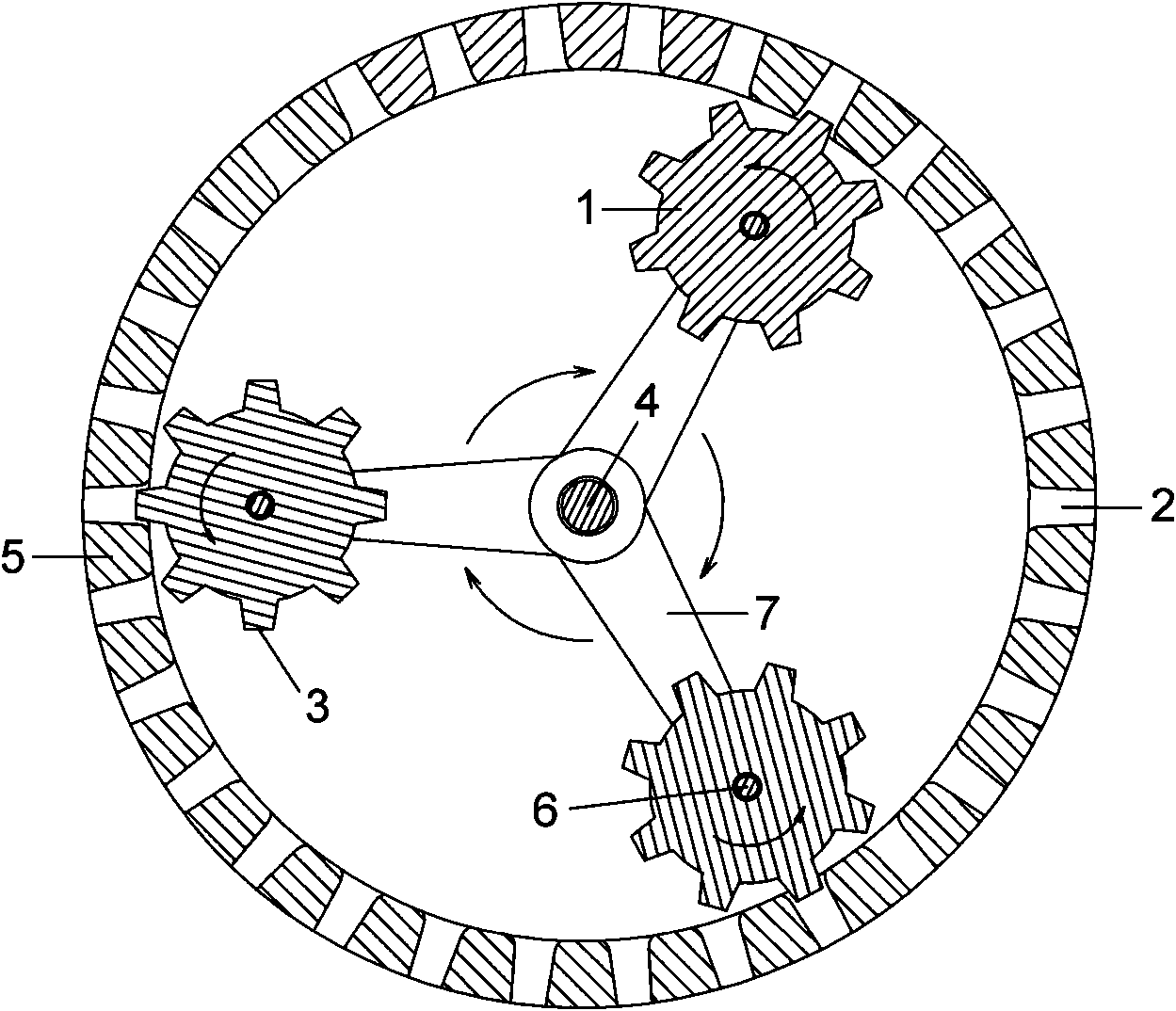

[0020] A composite biomass pressing molding equipment, which is composed of a double-rotation system, a ring die system and a feeding system; the double-rotation system is composed of a main rotation system and a secondary rotation system, and the main rotation system is rotated by the main rotation shaft 4 and the upper and lower groups Each group of rotating arms 7 is provided with three rotating arms 7, and each rotating arm 7 is fixed on the main rotating shaft 4, and the rotating arms 7 rotate with the rotation of the main rotating shaft 4, and the three rotating arms 7 altogether The vertical projections of the two sets of rotating arms 7 coincide with each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com