Device and technique for processing rope drill rod in medium-frequency induction way

A drill pipe and intermediate frequency technology, which is applied in the equipment and process field of intermediate frequency induction processing wireline drill pipe, which can solve the problems of poor heat treatment uniformity, low energy utilization rate, and low production efficiency of drill pipe, so as to ensure uniform heat treatment The effect of improving the comprehensive mechanical properties of drill pipe and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

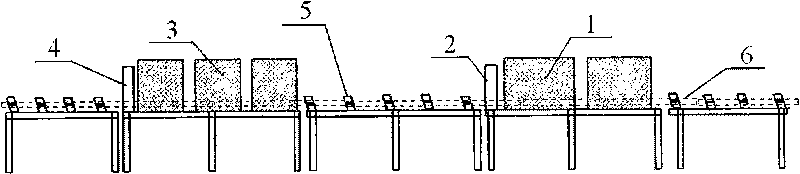

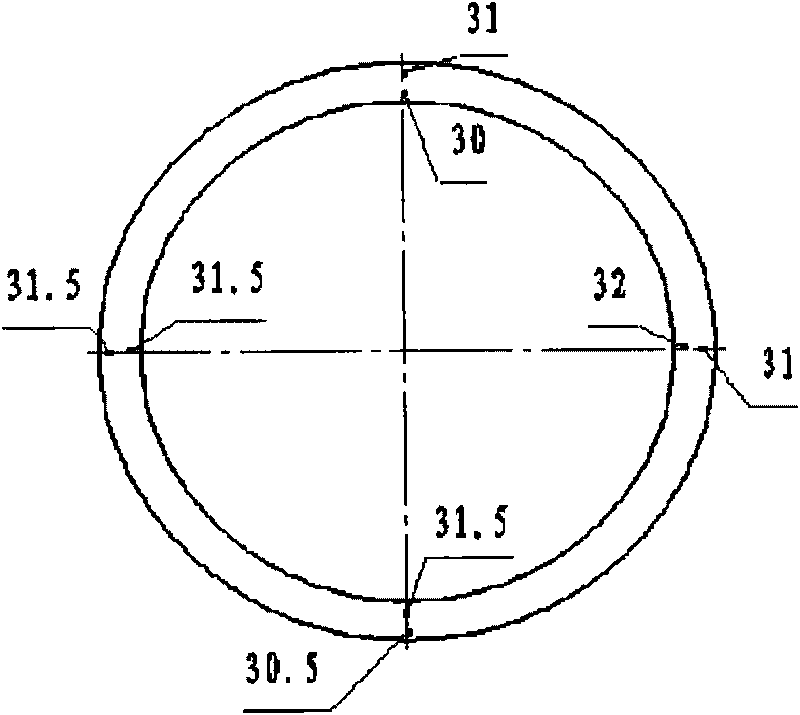

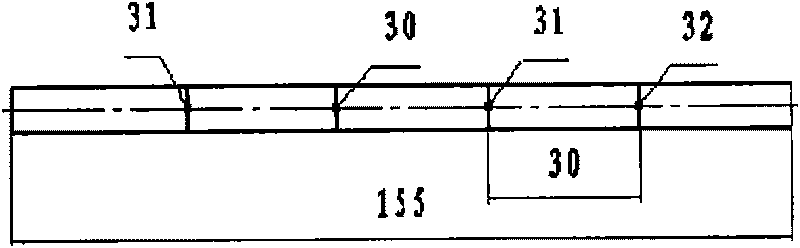

[0017] Such as figure 1 As shown, the equipment for the intermediate frequency induction processing rope drill pipe of the present invention mainly includes a quenching induction coil 1, a quenching spray cooling water circle 2, a tempering induction coil 3, a tempering spray water circle 4 and a driving drill pipe 6 The advancing frequency conversion speed regulating roller table 5 passes through the quenching induction coil 1 , the quenching spray cooling water circle 2 , the tempering induction coil 3 , and the tempering spray water circle 4 in sequence. Wherein there are at least two quenching induction coils 1 .

[0018] The process of medium frequency induction processing rope drill pipe adopts the production method of continuous induction heating step by step. The specific steps are as follows: first, place the drill pipe to be processed on the material rack, adjust the linear speed of the frequency conversion motor to the roller feeding mechanism, and The induction eq...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap