Method for recovering indium and tin from ITO waste target materials on basis of distillation

A distillation method and target material technology, applied in the field of comprehensive recovery of indium tin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The reaction of ITO powder and hydrochloric acid is:

[0016] In 2 o 3 +6HCl=2InCl 3 +3H 2 o

[0017] SnO 2 +4HCl=SnCl 4 +2H 2 o

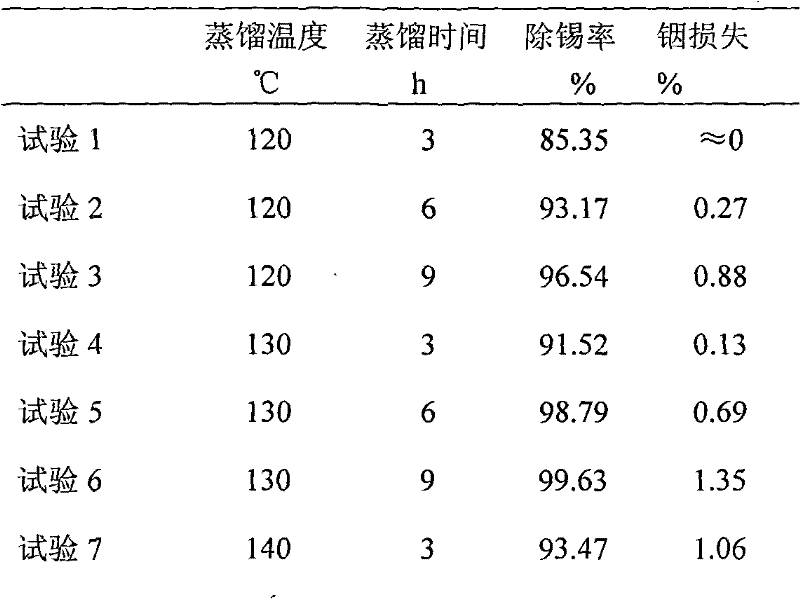

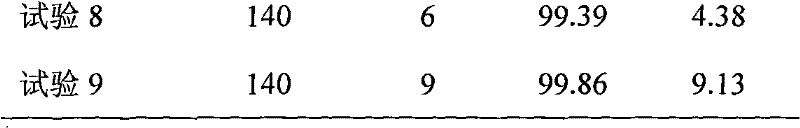

[0018] First leaching the ITO powder with hydrochloric acid, taking the leaching clear liquid for direct distillation, and controlling the temperature so that the SnCl 4 Distillation and separation, after the distillation, dissolve the retentate with dilute hydrochloric acid, adjust the pH value and replace directly, and the sponge indium obtained by the replacement is melted and cast to obtain crude indium. The distillate is received in two steps, the temperature 100 degrees receives SnCl 4 Hydrochloric acid solution, can continue to produce tin oxide or SnCl 4 crystallization.

[0019] 2. Experimental part

[0020] 2.1. Test raw materials

[0021] The ITO powder used in the test is obtained by crushing and ball milling waste ITO targets; industrial hydrochloric acid.

[0022] 2.2. Test steps

[0023] 2.2.1. Leaching

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com