Meter-class aluminum alloy forging ring quenching method

An aluminum alloy and ring forging technology is applied in the field of heat treatment of metal materials, which can solve the problems of reducing the dimensional accuracy of meter-grade aluminum alloy forging rings, achieve uniform cooling, improve dimensional accuracy, and reduce large deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

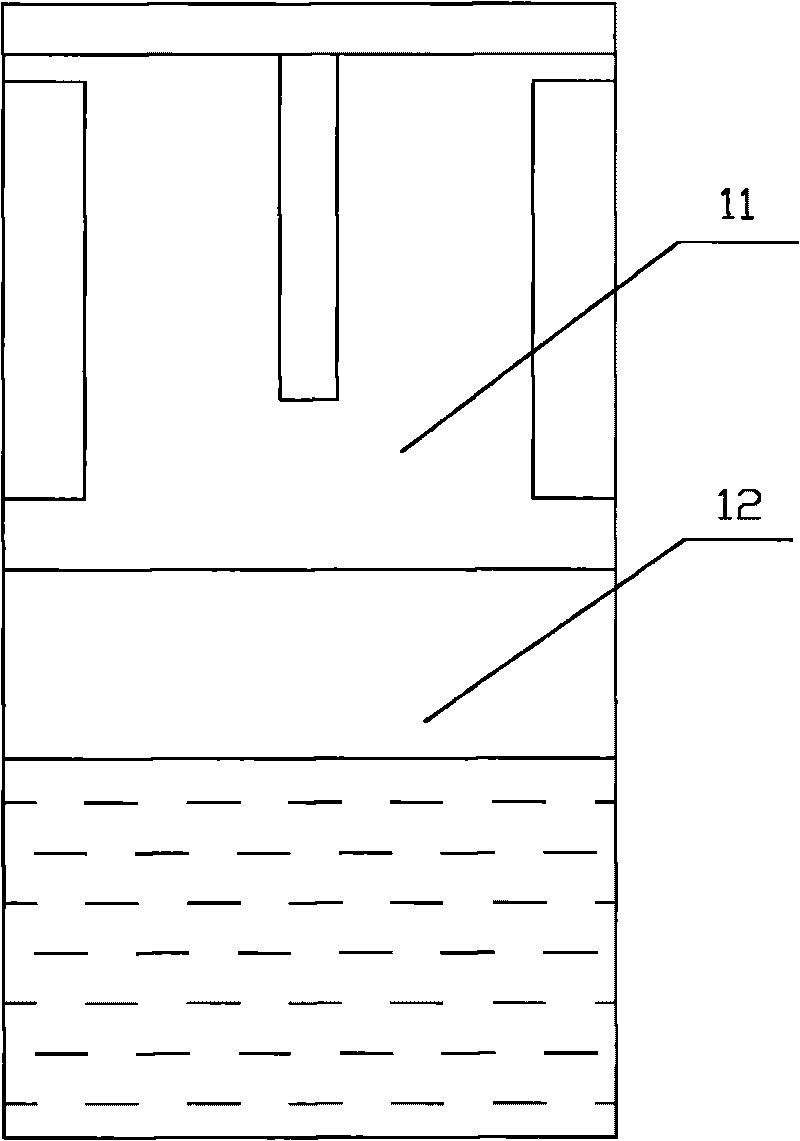

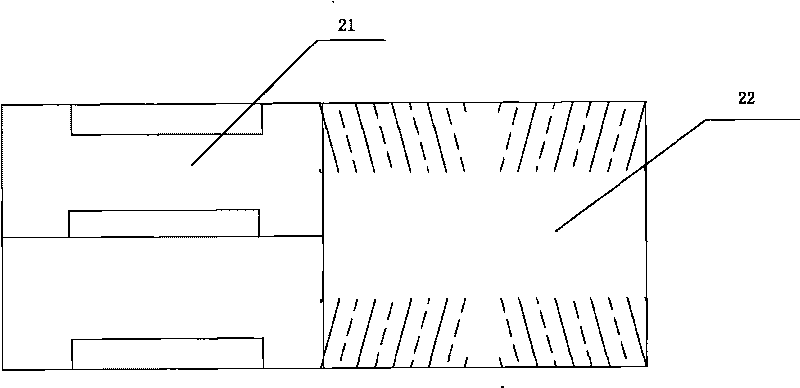

[0029] An embodiment of the method for quenching a meter-level aluminum alloy ring forging provided by the present invention includes:

[0030] Keep the horizontally placed meter-level aluminum alloy forging ring in the quenching furnace;

[0031] After heat preservation, use a quenching medium to simultaneously spray and quench the inner ring surface, the outer ring surface, the upper surface and the lower surface connecting the inner ring surface and the outer ring surface of the meter-grade aluminum alloy forged ring.

[0032] According to the present invention, the aluminum alloy is not particularly limited, and specific examples may be 6061 aluminum alloy forged ring and 7075 aluminum alloy forged ring, but not limited thereto. The meter-level aluminum alloy forged ring in the present invention refers to an aluminum alloy forged ring with a diameter of more than 1 meter, preferably a meter-level aluminum alloy forged ring with a diameter of more than 2 meters.

[0033] A...

Embodiment 1

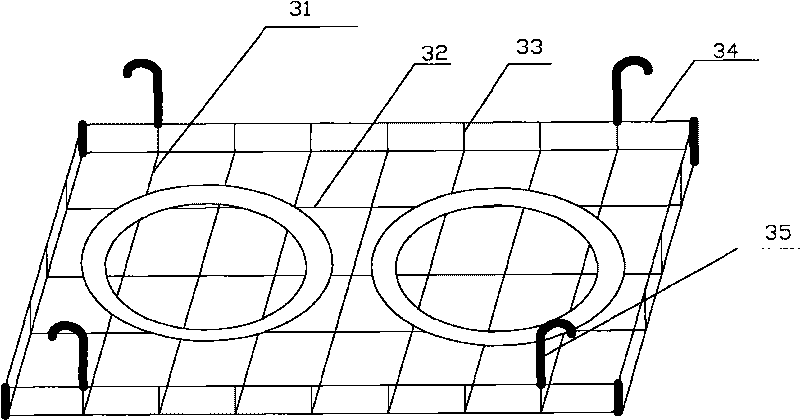

[0040] Place the 6061 three-meter aluminum alloy forging ring horizontally on the forging ring support frame.

[0041] Hang the forging ring support frame with the horizontal three-meter-level aluminum alloy forging ring horizontally on the roller table of the roller hearth furnace, turn on the switch of the roller table, and the forging ring enters the roller hearth furnace along with the forging ring support frame of the roller hearth furnace to keep warm. to 495°C, and the holding time was 2 hours.

[0042] After heat preservation, turn on the spraying device, and spray water on the inner ring surface, outer ring surface, and the upper surface and lower surface connecting the inner ring surface and the outer ring surface of the three-meter aluminum alloy forging ring to complete the horizontal spray cooling at the same time Quenching.

[0043] The spraying time is 10 minutes, the furnace door is opened, the forged ring is released from the furnace through the roller table,...

Embodiment 2

[0045] Place the 7075 two-meter-grade aluminum alloy forging ring horizontally on the forging ring support frame.

[0046] Hang the forging ring support frame with the horizontal 2-meter-level aluminum alloy forging ring on the roller table of the roller hearth furnace horizontally, turn on the switch of the roller table, and the forging ring enters the roller hearth furnace along with the forging ring support frame of the roller hearth furnace to keep warm. 500°C, and the holding time is 3 hours.

[0047] After heat preservation, turn on the spraying device, and spray water on the inner ring surface, outer ring surface, and the upper surface and lower surface connecting the inner ring surface and the outer ring surface of the meter-level aluminum alloy forging ring to complete the quenching. .

[0048] The spraying time is 12 minutes, the furnace door is opened, the forging ring is released from the furnace through the roller table, and the quenching process is completed. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com