Bellow-type mixed medium vibration isolating and absorbing unit

A technology of mixed medium and bellows, applied in the direction of shock absorbers, can solve the problems of the structure being difficult to meet the requirements of heavy-load low-frequency vibration isolation, the fatigue life of the bellows being reduced, and the instability of the bellows. Easy to use and maintain, and the effect of large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

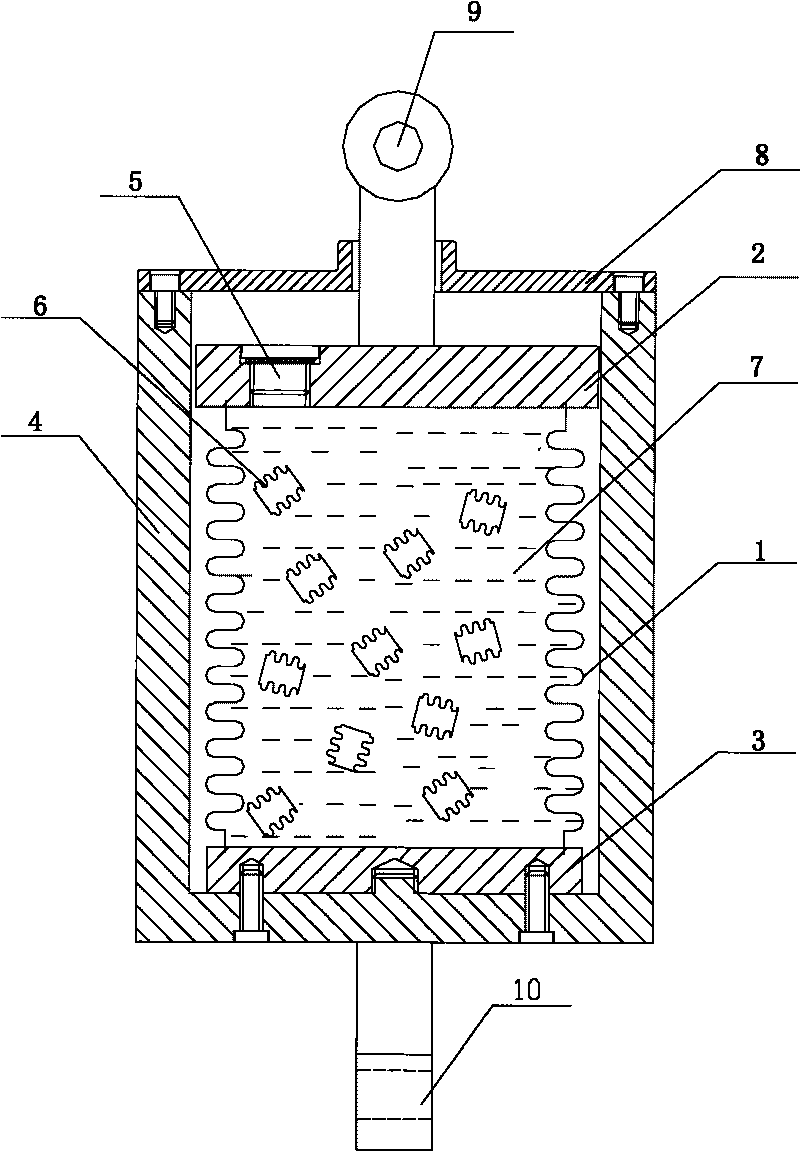

[0037] Such as figure 1 As shown, a bellows type mixed-medium vibration isolation shock absorber includes a bellows 1, and the two ends of the bellows 1 are welded on the upper end plate 2 and the lower end plate 3 to form a bellows container, and the bellows container Placed in the guide sleeve 4, the bottom of the bellows container and the guide sleeve 4 are fixedly connected by a set of bolts, and there is a gap between the side wall of the bellows 1 and the side wall of the guide sleeve 4 ;

[0038] The bellows container is provided with a circular opening 5, and the bellows container is filled with a liquid-solid mixed medium composed of an elastic unit body 6 and a liquid 7 through the circular opening 5, and sealed with countersunk bolts; The unit body 6 is a metal bellows welded and sealed at both ends, and the cavity of the elastic unit body 6 is filled with atmospheric nitrogen;

[0039] The top of the guide sleeve 4 is fixedly connected with a limit plate 8 to pre...

Embodiment 2

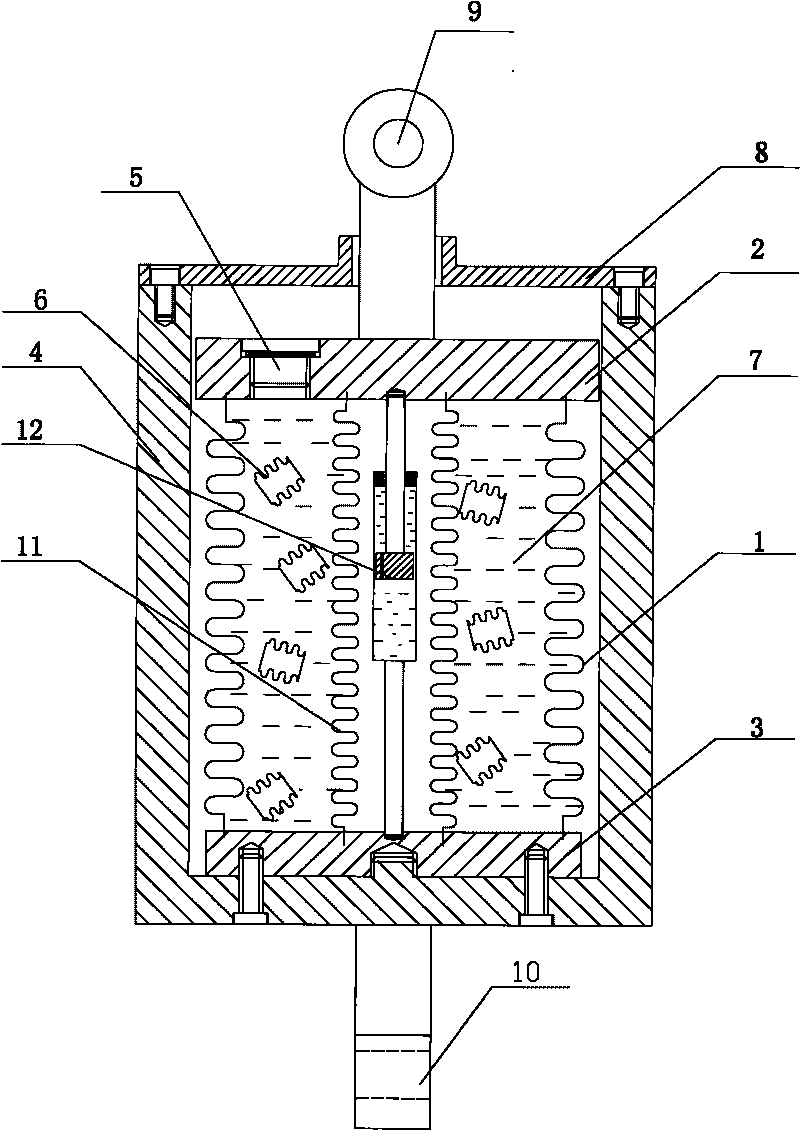

[0042] Such as figure 2 As shown, a bellows type mixed-medium vibration isolation shock absorber includes a bellows 1, and the two ends of the bellows 1 are welded on the upper end plate 2 and the lower end plate 3 to form a bellows container, and the bellows container Placed in the guide sleeve 4, the bottom of the bellows container and the guide sleeve 4 are fixedly connected by a set of bolts, and there is a gap between the side wall of the bellows 1 and the side wall of the guide sleeve 4 ;

[0043] The bellows container is provided with a circular opening 5, and the bellows container is filled with a liquid-solid mixed medium composed of an elastic unit body 6 and a liquid 7 through the circular opening 5, and sealed with countersunk bolts; The unit body 6 is a metal bellows welded and sealed at both ends, and the cavity of the elastic unit body 6 is filled with atmospheric nitrogen;

[0044] The bellows container is provided with an inner bellows 11, and the two ends ...

Embodiment 3

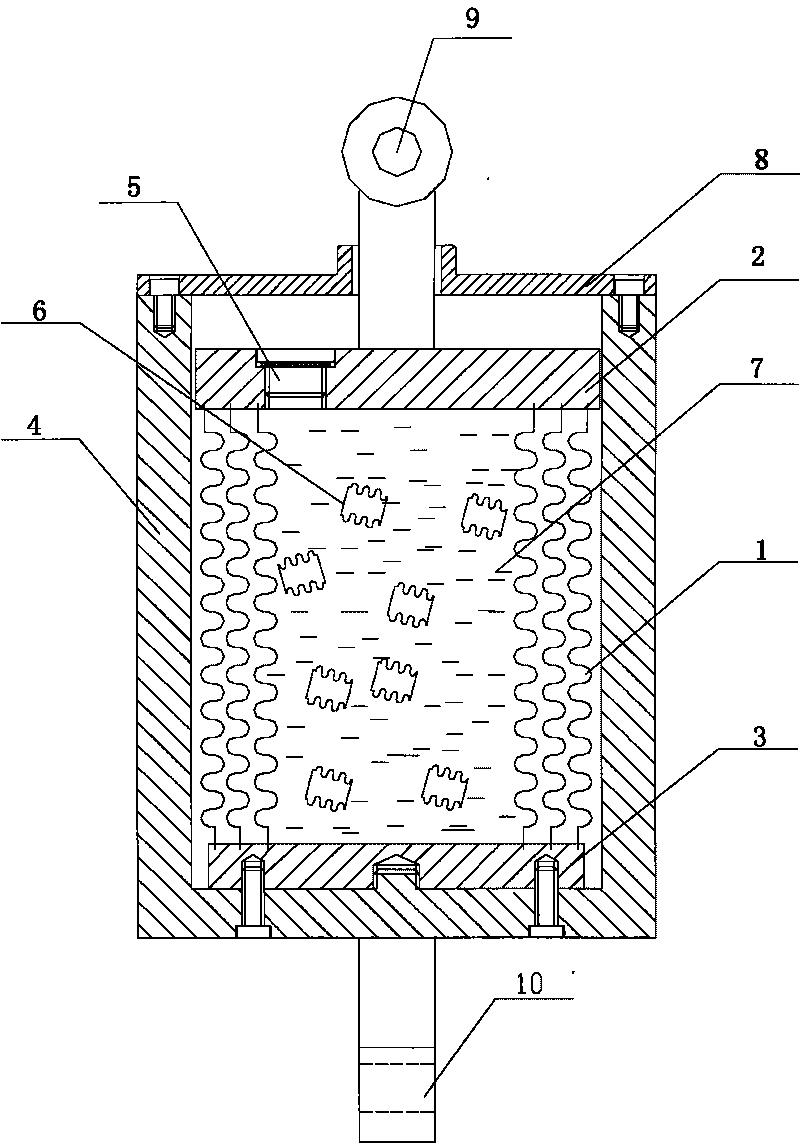

[0049] Such as image 3 As shown, a bellows-type mixed-medium vibration isolation damper includes a bellows 1, and the bellows 1 is a three-layer bellows formed by coaxial nesting of three multi-layer bellows with different cross-sectional radii. The two ends of each bellows 1 are respectively fixedly connected to the upper end plate 2 and the lower end plate 3 to form a bellows container, and the gap between the three-layer bellows 1 is filled with atmospheric air; the bellows container is placed in the guide In the sleeve 4, the bottom of the bellows container and the guide sleeve 4 are fixedly connected by a set of bolts, and there is a gap between the side wall of the bellows 1 and the side wall of the guide sleeve 4;

[0050] The bellows container is provided with a circular opening 5, and the bellows container is filled with a liquid-solid mixed medium composed of an elastic unit body 6 and a liquid 7 through the circular opening 5, and sealed with countersunk bolts; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com