Laser backlight surface light source

A technology of laser light source and backlight surface, applied in the field of laser display, can solve the problems of small color gamut, difficulty in starting at low temperature, non-compliance with environmental protection standards, etc., and achieve the effect of improving spatial resolution and improving energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

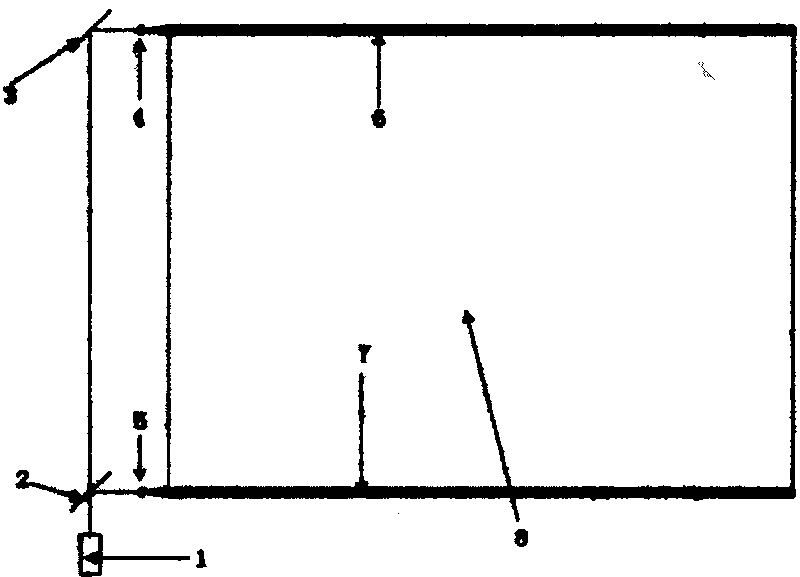

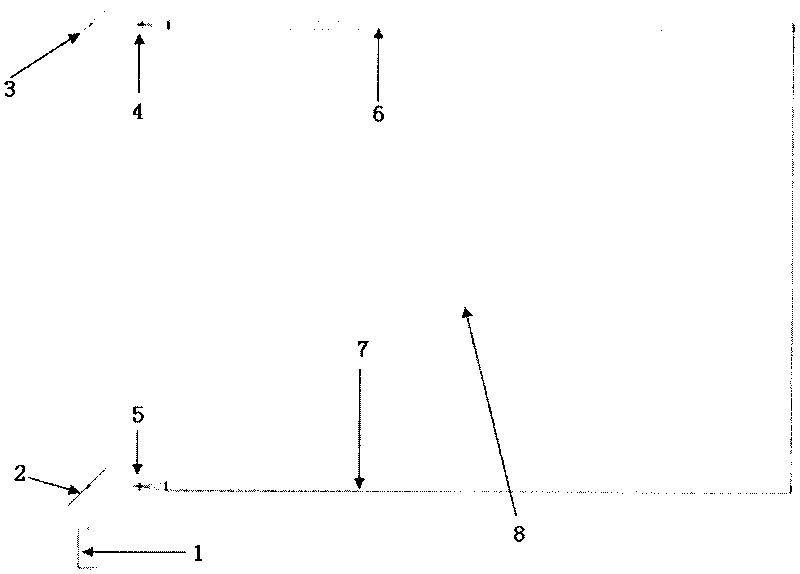

[0020] Such as figure 1 As shown, the laser backlight surface light source of the present invention includes a laser light source 1, a beam splitter mirror 2, a broadband dielectric film high reflection mirror 3, a beam expander mirror 4 and a beam expander mirror 5, a micro light guide rod 6, a micro light guide rod 7 and a backlight module 8. The laser light source 1 is located in front of the beam splitter 2, the broadband dielectric film high reflection mirror 3 is located behind the beam splitter 2, and the beam expander 4 and the beam expander 5 are respectively located at the beam splitter 2 and the broadband dielectric film high reflection mirror 3. Two fine light guide rods 6 and 7 are inlaid on the upper and lower sides of the light guide plate 10 in the backlight module 8, and are located on one side of the beam expander 4 and the beam expander 5 respectively.

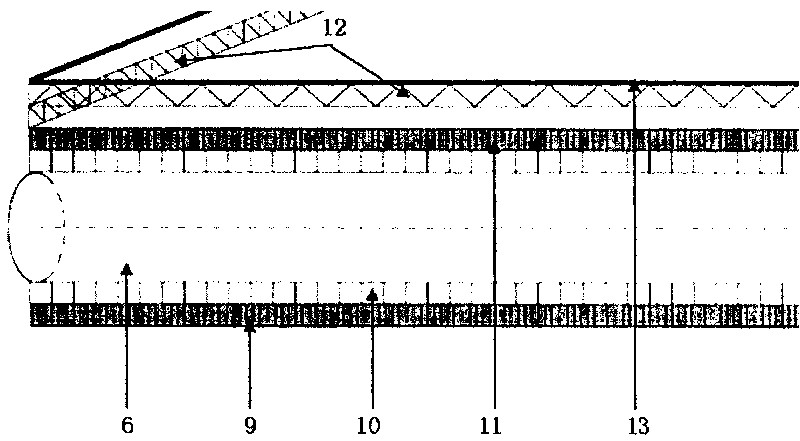

[0021] Such as figure 2 As shown, the structure and function of the backlight module 8 are similar to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com