Superconducting magnetic separator

A superconducting magnetic and electromagnetic technology, which is applied in the field of superconducting electromagnetic beneficiation equipment or superconducting electromagnetic equipment for removing metal or metal compounds, can solve the problems of high magnetic field gradient, complex structure of superconducting electromagnetic separator, and low utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A superconducting electromagnetic separator of the present invention will be described below in conjunction with specific embodiments. The described embodiments are for better illustration of the present invention, and should not be construed as limitations on the claims of the present invention.

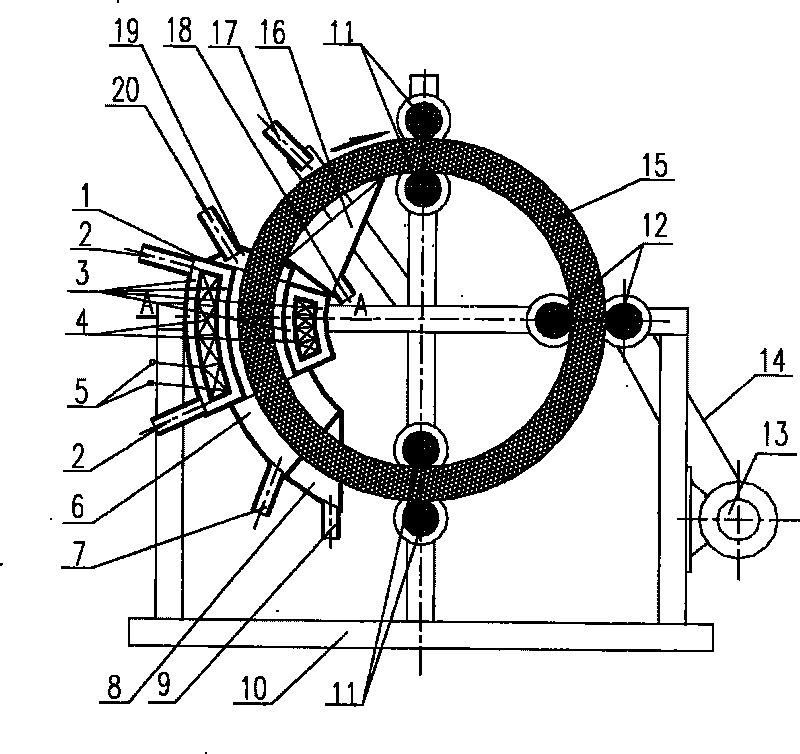

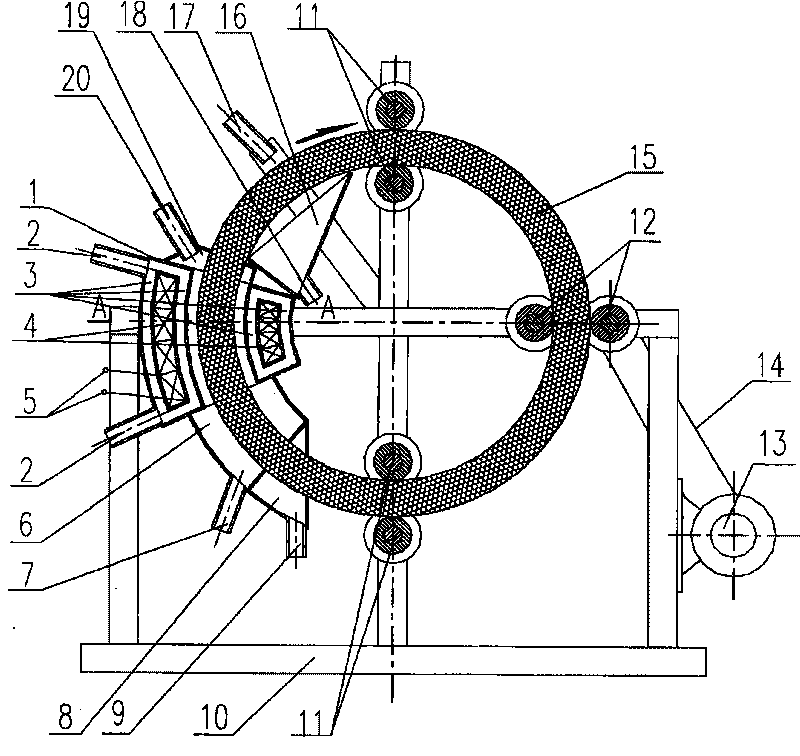

[0018] Implementations such as figure 1 Shown is a schematic diagram of the structure of a superconducting electromagnetic separator. The structure of the superconducting electromagnetic separator consists of a superconducting magnetic system, a magnetic wire drum 15, a magnetic wire drum positioning system, a magnetic wire drum driving system, a superconducting electromagnetic separator bracket 10, a feed trough 19, and a dispersed selection tank. 6. It is composed of the tailings collection tank 8 and the extract recovery system.

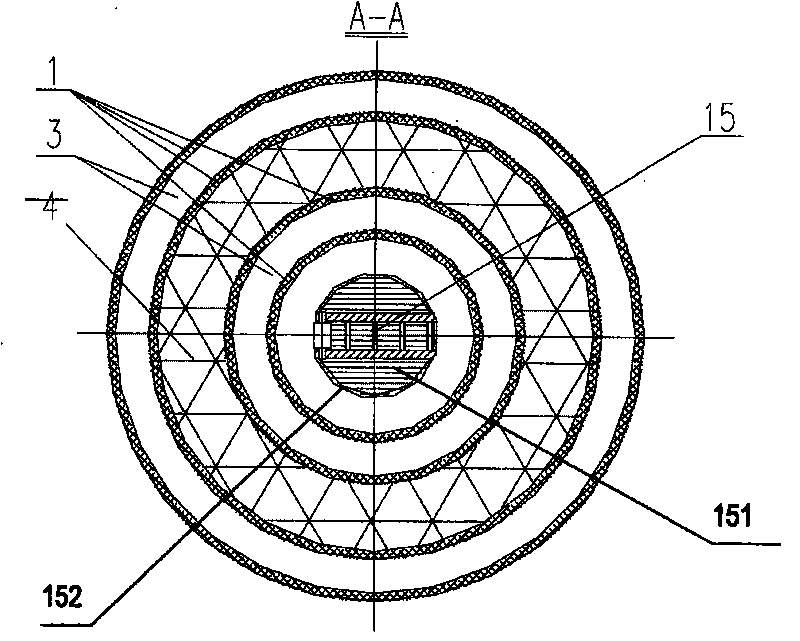

[0019] The superconducting magnetic system includes a superconducting magnetic system housing 1 and a magnetic core coil 4; 2 to 4 short tubes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com