Device for automatically controlling semicontinuous casting liquid level of aluminum and aluminum alloy

A liquid level automatic control and aluminum alloy technology, which is applied in the field of aluminum and aluminum alloy semi-continuous casting liquid level automatic control devices, can solve the problems such as the inability to guarantee the core link liquid level control, etc., to improve internal quality and surface quality, and improve product quality. The effect of high quality and control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

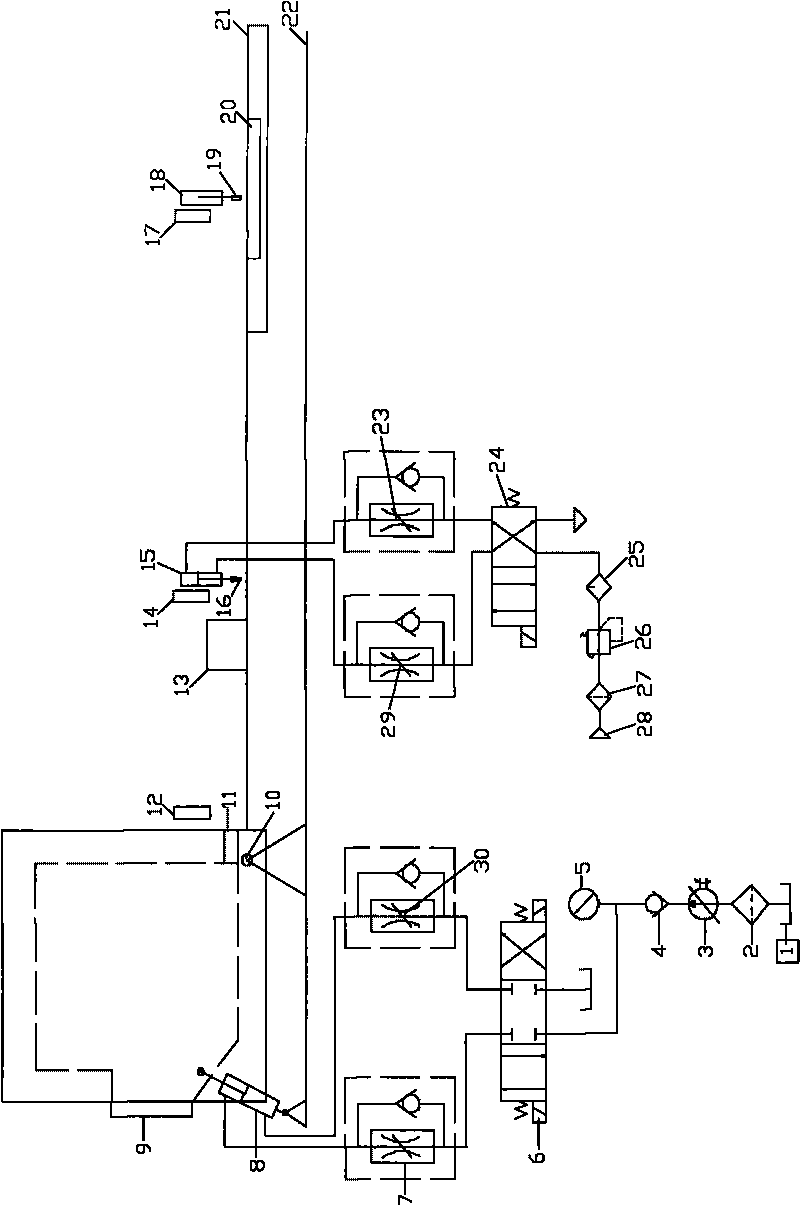

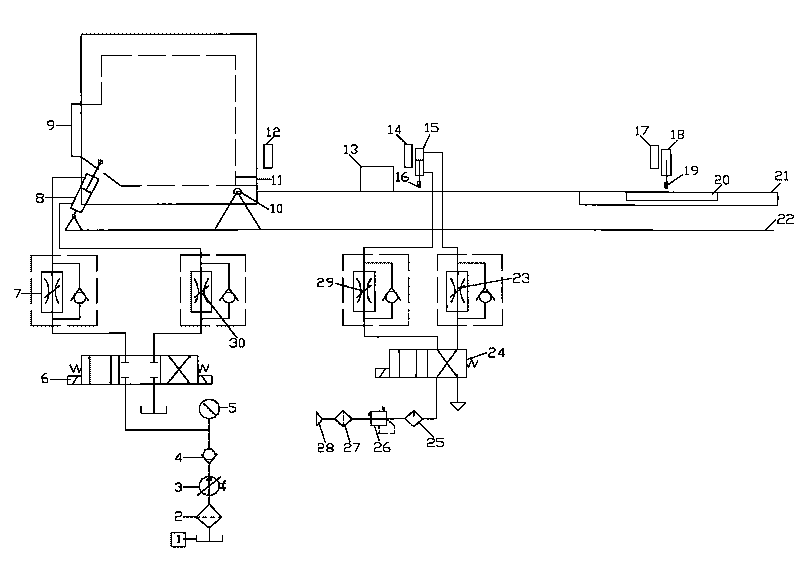

[0020] Such as figure 1 As shown, the aluminum and aluminum alloy semi-continuous casting liquid level automatic control device includes the melting furnace control part, launder control part and casting platform control part. The melting furnace control part includes oil tank 1, hydraulic pump 3, solenoid valve 6 and hydraulic cylinder 8. One side of the melting furnace is supported on the foundation 22 through the rotating shaft 10, and the other side of the melting furnace is hinged with the piston rod of the hydraulic cylinder 8. The furnace mouth 11 of the melting furnace is located on the side of the rotating shaft. Position measuring instruments 12 are installed at 11 places, the furnace door 9 of the smelting furnace is located on the side of the hydraulic cylinder, the cylinder barrel of the hydraulic cylinder 8 is hinged on the foundation 22, and the hydraulic cylinder (8) is connected to the solenoid valve 6 through a pipeline. 8 and the oil inlet pipeline of the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com