Production device and method of high purity trichlorosilane by using heat pump distillation

A high-purity trichlorosilane heat pump and production device technology, applied in the field of energy-saving separation of high-purity trichlorosilane, can solve the problems of serious pollution and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

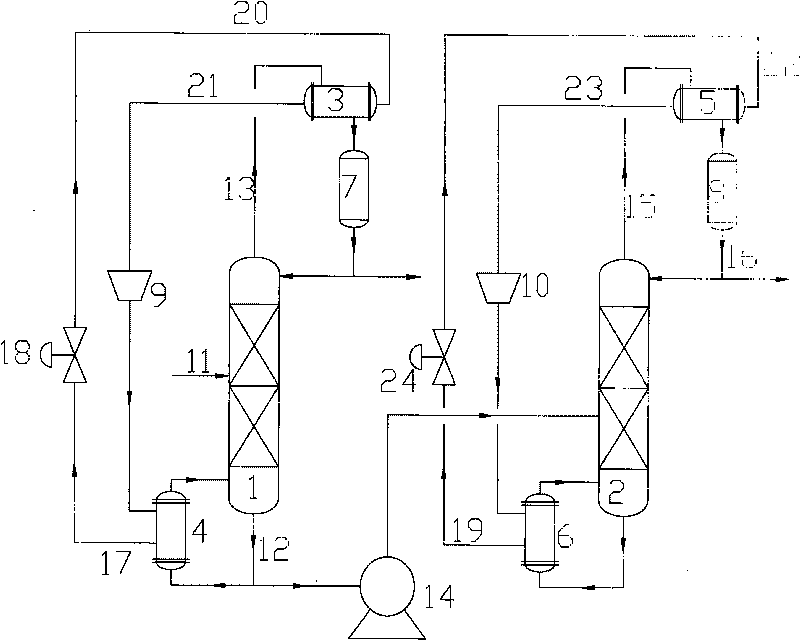

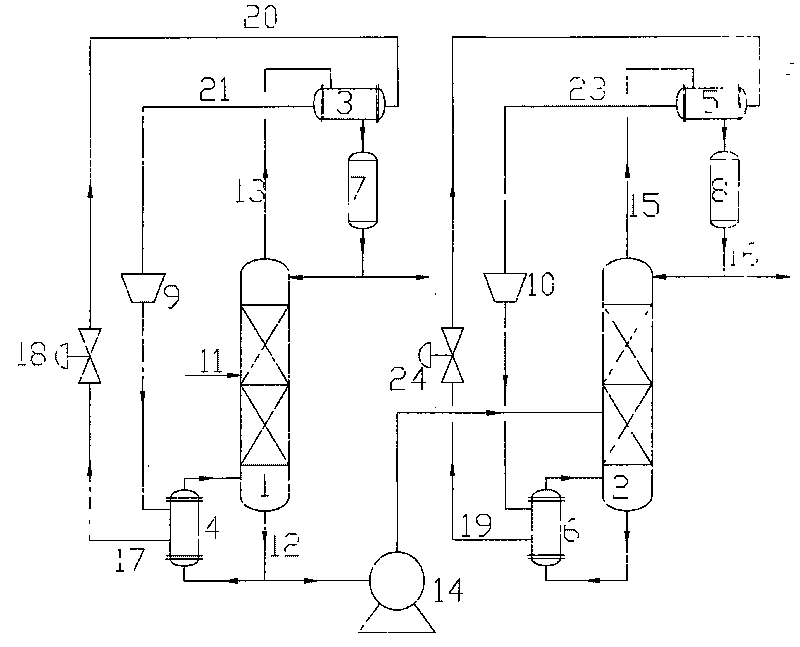

[0021] Take the purification of trichlorosilane in the production of 2000 tons / year polysilicon as an example. The production device includes a de-light tower, a de-weight tower and a heat pump device. The two towers are respectively equipped with a condenser and a reboiler. In the heat pump device, one end of the condenser is connected to the reboiler through a compressor through a pipeline, and the other end of the reboiler is It is connected to one end of the condenser through a pressure reducing valve. Among them, the pressure of the light removal tower is 300KPa, the temperature of the tower top is 60°C, and the reflux ratio is 20; the pressure of the weight removal tower is 600KPa, the temperature of the tower top is 80°C, and the reflux ratio is 3.

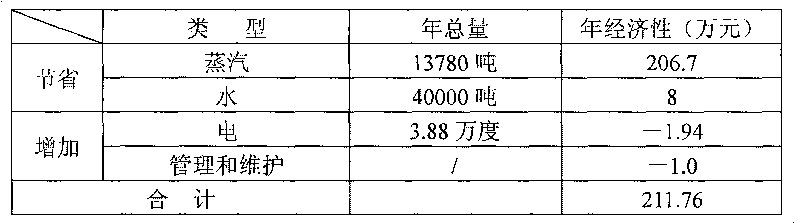

[0022]The annual running time is calculated at 8000h / year, the steam price is calculated at 150 yuan / ton, the electricity price is calculated at 0.5 yuan / Kwh, and the water price is calculated at 2.0 yuan / ton:

[0023] Aft...

Embodiment 2

[0026] Take the purification of trichlorosilane in the production of 1000 tons / year polysilicon as an example. The production device includes a de-light tower, a de-weight tower and a heat pump device. The two towers are respectively equipped with a condenser and a reboiler. In the heat pump device, one end of the condenser is connected to the reboiler through a compressor through a pipeline, and the other end of the reboiler is It is connected to one end of the condenser through a pressure reducing valve. Among them, the pressure of the light removal tower is 300KPa, the temperature at the top of the tower is 70°C, and the reflux ratio is 50; the pressure of the light removal tower is 600KPa, the temperature at the top of the tower is 90°C, and the reflux ratio is 10.

[0027] The annual running time is calculated at 8000h / year, the steam price is calculated at 150 yuan / ton, the electricity price is calculated at 0.5 yuan / Kwh, and the water price is calculated at 2.0 yuan / ton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com