Method for circularly purifying manganese sulfate and manganese carbonate

A purification method, manganese carbonate technology, applied in the direction of manganese sulfate, chemical instruments and methods, manganese compounds, etc., can solve the problem that the content of calcium and magnesium ions cannot meet the needs of development, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

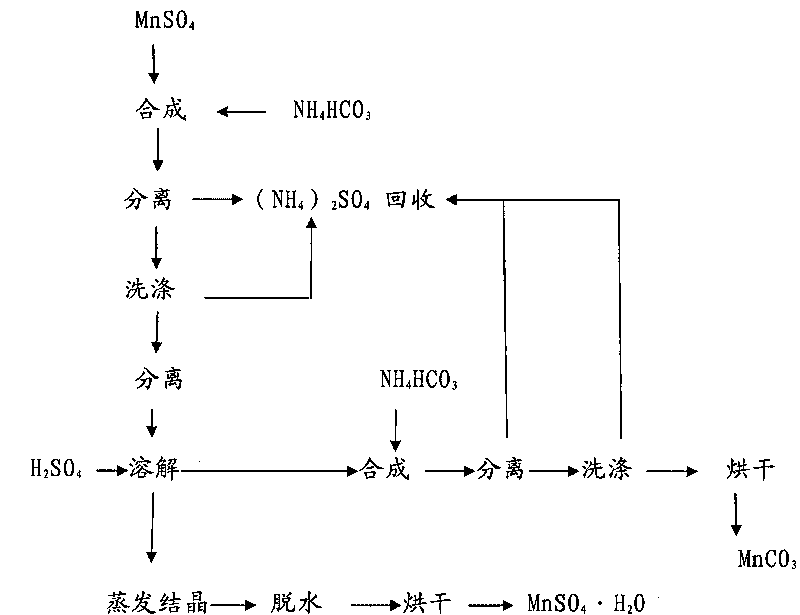

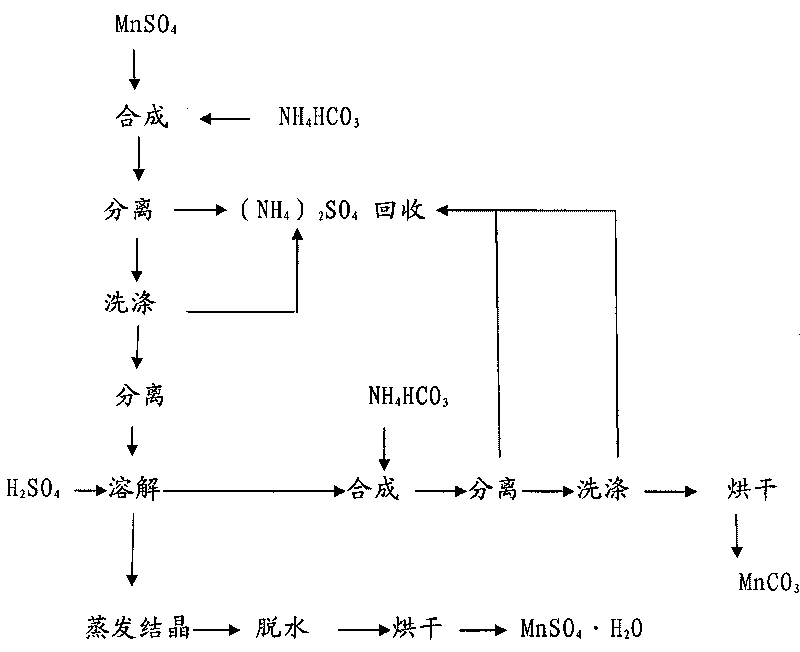

Method used

Image

Examples

Embodiment 1

[0014] 354g / L MnSO 4 Put 4000ml of the solution in a 5000ml beaker, control the temperature at 50°C, and slowly add food-grade NH under stirring 4 HCO 3 1514g, separated by suction filtration, filtrate recovery (NH 4 ) 2 SO 4 , the solid was washed twice at 80°C with a material-to-water ratio of 1:5, and part of it was dried into MnCO 3 1 # .

[0015] The manganese carbonate after above-mentioned washing is placed in the beaker of 5000ml, adds a small amount of deionized water to make a slurry, with 6mol / L H 2 SO 4 React until the pH value is 1, heat and boil with washed MnCO 3 Adjust the pH value to 4, filter with slow qualitative filter paper, discard the filter residue, evaporate the filtrate to crystallize, and dry the crystallization in an oven at 80-85°C for 20 hours to obtain MnSO 4 ·H 2 O sample 1 # .

Embodiment 2

[0017] 354g / L MnSO 4 Place the solution in a 5000ml beaker, control the temperature at 55°C, and slowly add food-grade NH under stirring 4 HCO 3 1514g, separated by suction filtration, filtrate recovery (NH 4 ) 2 SO 4 , The solid was washed twice at 100°C with a material-to-water ratio of 1:5.

[0018] The above washed MnCO 3 Add a small amount of deionized water for beating, and use 9mol / L H 2 SO 4 React to a pH of 2, heat and boil with washed MnCO 3 Return to pH 5, filter with slow qualitative filter paper, discard the filter residue, put the filtrate in a 5000ml beaker, control the temperature within 55°C, and slowly add equimolar NH 4 HCO 3 Synthesis, solid-liquid separation, liquid recovery (NH 4 ) 2 SO 4 , the solid was washed twice at 100°C with a material-to-water ratio of 1:5, dehydrated and dried in a vacuum oven at 85°C for 16 hours to obtain MnCO 3 sample 2 # .

Embodiment 3

[0020] Repeat Example 1, the difference is that the 12mol / L H that adds 2 SO 4 , slowly add food-grade NH to the manganese sulfate solution with stirring at a temperature of 60 4 HCO 3 , get MnCO 3 sample 3 # and MnSO 4 ·H 2 O sample 3 # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com