Steel hydrochloric acid pickling corrosion inhibitor

A technology of pickling corrosion inhibitor and hydrochloric acid, which is used in the fields of pickling corrosion inhibitor, hydrochloric acid pickling rust removal, boiler and other industrial equipment cleaning, and can solve the problem of unstable corrosion inhibition performance, affecting process quality, Surface roughness of steel parts and other problems, to achieve excellent wetting, improve rapid wetting, and prevent corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

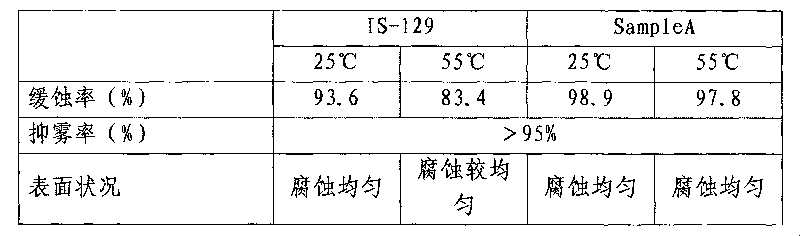

[0015] Experimental conditions: the concentration of hydrochloric acid for pickling is 8%, the pickling temperatures are 25°C and 55°C respectively, and the comparative corrosion inhibitor is IS-129 hydrochloric acid pickling corrosion inhibitor. The amount of corrosion inhibitor added is 3‰ of the mass of hydrochloric acid. The steel parts used in the experiment are A3 steel pipes. The experimental results are as follows:

[0016]

[0017] Experimental results show that the present invention can maintain its excellent corrosion inhibition performance in a wide temperature range. When the temperature continues to rise, the amount of corrosion inhibitor added can be increased according to the situation.

Embodiment 2

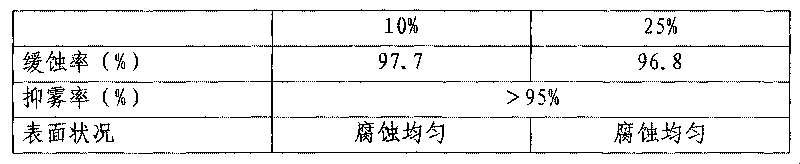

[0019] Experimental conditions: the concentrations of hydrochloric acid for pickling are 10% and 25% respectively, and the pickling temperature is 30°C. According to the concentration of hydrochloric acid, the addition amount of the corrosion inhibitor of the present invention is respectively 3‰ and 5‰, and the steel parts used are A3 steel pipes . The experimental results are:

[0020]

[0021] Properly adjusting the addition amount of the corrosion inhibitor of the present invention can also obtain excellent corrosion inhibition effects under different concentrations of hydrochloric acid. As the experimental results show, the corrosion inhibition rates are all above 95%.

[0022] Corrosion inhibitors using imidazoline derivatives or urotropine as corrosion inhibitors have the disadvantage of unstable corrosion inhibition performance. The reason is that imidazoline derivatives and urotropine are unstable and easy to decompose. In the present invention, by adding acetyleni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com