Preparation method of common pole-type thin film solar cell

A technology of thin-film solar cells and common electrodes, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as forced cooling of solar cells and temperature rise of solar cells, and achieve increased short-circuit current density, increased replacement efficiency, and stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

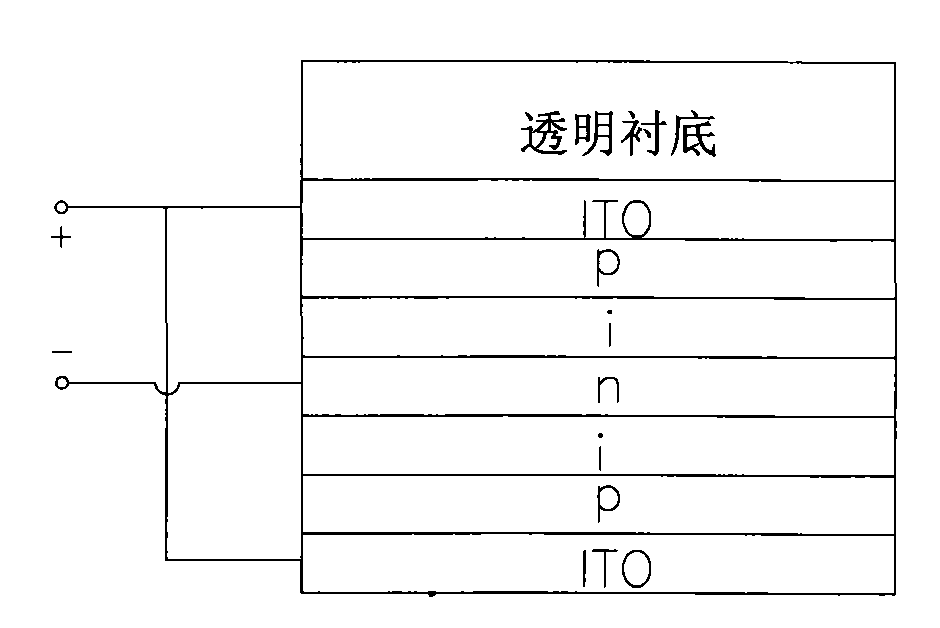

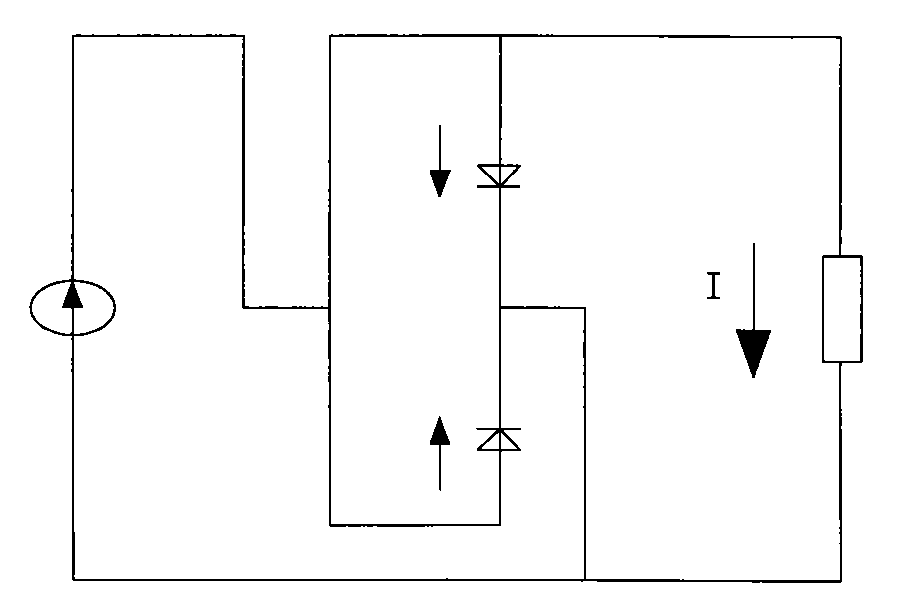

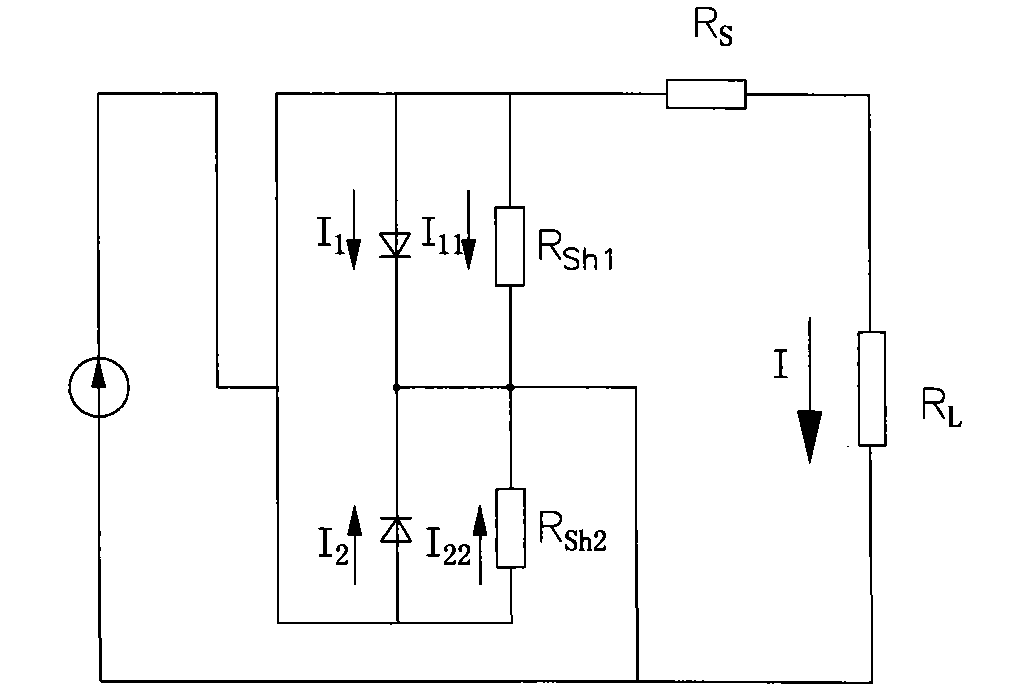

[0020] 1. Structural design of solar cells

[0021] Design p on transparent substrate + / p / i / n / i / p / p + Structured common-pole thin-film solar cells. Increase P + It is to reduce the contact resistance, increase the short-circuit current and open-circuit voltage; at the same time, the direct lead-out electrode of the n-layer avoids the large-area contact between the n-layer and the metal electrode. p + / p / i / n and other layers of optical band gap E g Gradually decreasing, it can effectively expand the spectral absorption range; at the same time, it also has a certain inhibitory effect on the formation of the incubation layer during film preparation, thereby increasing the open circuit voltage and fill factor.

[0022] 2. Preparation of common electrode thin film solar cells

[0023] Hereinafter, the present invention takes nano-silicon as an example to illustrate the preparation of a copolar thin-film solar cell.

[0024] 2.1 Cleaning of transparent substrate

[0025] 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com