Biologic degradable magnesium alloy medicine supporter for reconstructing blood circulation and preparation method

A technology for degrading polymers and magnesium alloys, applied in stents, pharmaceutical devices, medical science, etc., can solve the problems of poor targeting, difficulty in promoting angiogenesis, and short half-life, so as to delay the degradation time and benefit Restoration of function, in vivo effect, less inflammatory response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

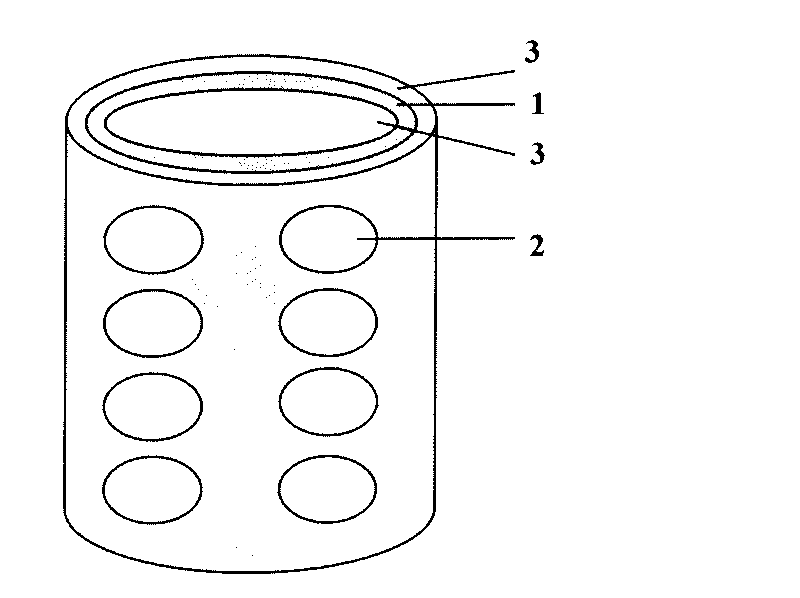

[0024] A biodegradable magnesium alloy drug stent for revascularization, including a hollow tube 1, the hollow tube is made of magnesium-aluminum alloy with a magnesium mass percentage of 99.9%, the inner diameter of the tube is 2.4 mm, and the wall thickness is 0.3 mm. The length is 0.5 cm, and the wall of the hollow tube is provided with 8 small holes 2 with a diameter of 0.2 mm through the wall. For ester layer 3, the ratio of basic fibroblast growth factor, heparin and polycaprolactone is 30ug:20mg:0.2g.

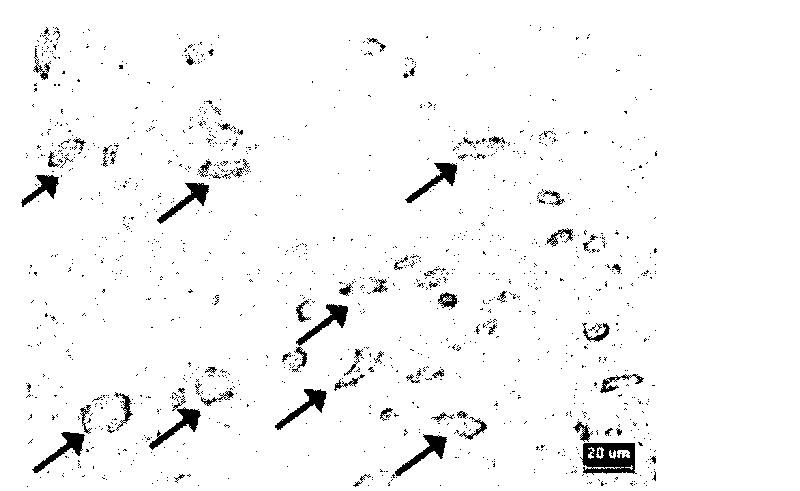

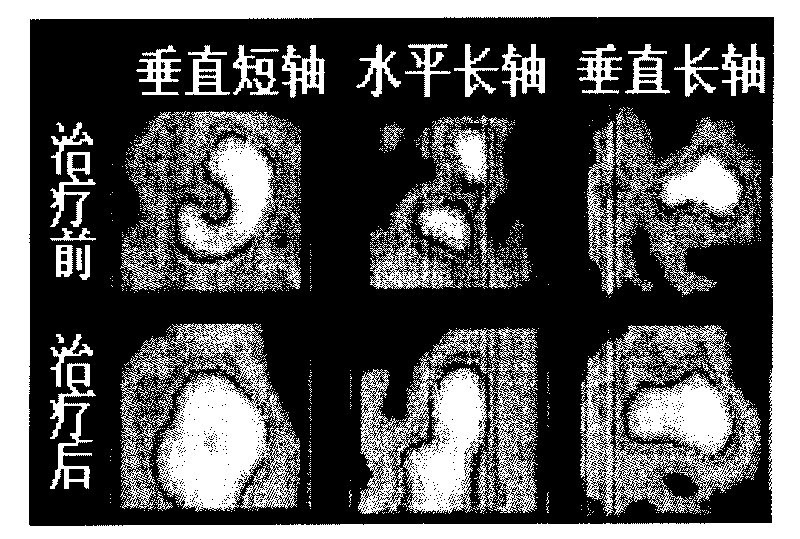

[0025] Myocardial revascularization animal experiment The experimental pig was anesthetized by injection of pentobarbital sodium to establish a myocardial ischemia model. The thorax and pericardium were opened along the median of the sternum to expose the heart. After penetrating the heart wall, the blood is ejected from the heart cavity, and the biodegradable magnesium alloy drug stent for revascularization prepared by the present invention is quickly placed in the myoc...

Embodiment 2

[0027] A method for preparing a biodegradable magnesium alloy drug stent for revascularization, comprising the following steps: using magnesium as a material to prepare a hollow tubular stent with an inner diameter of 2.4mm, a wall thickness of 0.3mm, and a length of 1cm by mechanical processing, and using electric The mechanical drill drills evenly through small holes around the side wall of the tube, the hole diameter is 1mm, the number of small holes is 4 per week, and there are 16 small holes in 4 rows. Add dichloromethane to polycaprolactone-polylactic acid copolymer (the molar ratio is 60 / 40), make the dichloromethane solution of the polymer that concentration is 10% (g / ml), fully stir, dissolve, take above-mentioned solution 1ml, take the β-type transforming growth factor of 50ug to disperse evenly In the dichloromethane solution of the polymer, add it to the syringe, and under the voltage of 13KV and the flow rate of 10ul / ml, the nanofibers are made by electrospinning e...

Embodiment 3

[0029] A method for preparing a biodegradable magnesium alloy drug stent for revascularization, comprising the following steps: using a magnesium-manganese alloy with a magnesium mass percentage of 90% as a material and preparing it into an inner diameter of 2.4 mm and a wall thickness of 0.3 mm by mechanical processing. mm, a hollow tube with a length of 3 cm, use an electromechanical drill bit with a diameter of 1 mm to evenly punch through small holes on the side wall of the tube, the number of small holes is 50, and dichloromethane is added to the polycaprolactone-polylactic acid copolymer (the molar ratio is 60 / 40), be made into the methylene chloride solution of the polycaprolactone-polylactic acid copolymer that concentration is 15% (g / ml), fully stir, dissolve; By the ratio of 50ug: 40mg, β Type transforming growth factor and heparin were uniformly dispersed in 1ml polycaprolactone-polylactic acid copolymer in dichloromethane solution, and evenly sprayed on the inner an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com