Extraction kettle with fluid distributor

A technology of fluid distributor and extraction kettle, which is applied in solvent extraction, separation methods, chemical instruments and methods, etc., can solve the problems of supercritical fluid flow channel blockage, increased pretreatment cost, and reduced mass transfer efficiency, so as to reduce energy consumption The effect of consumption, improvement of raw material utilization rate, and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

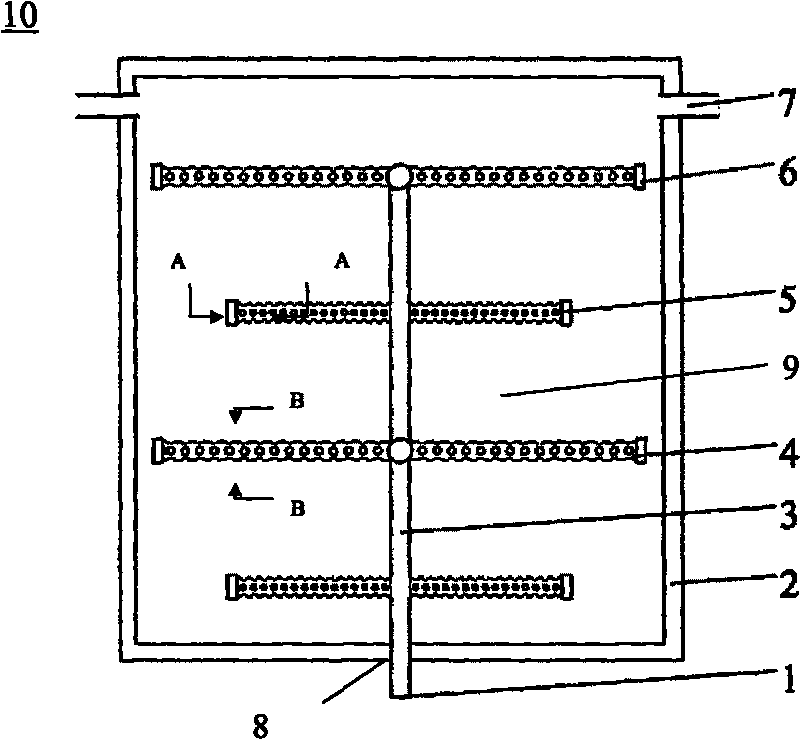

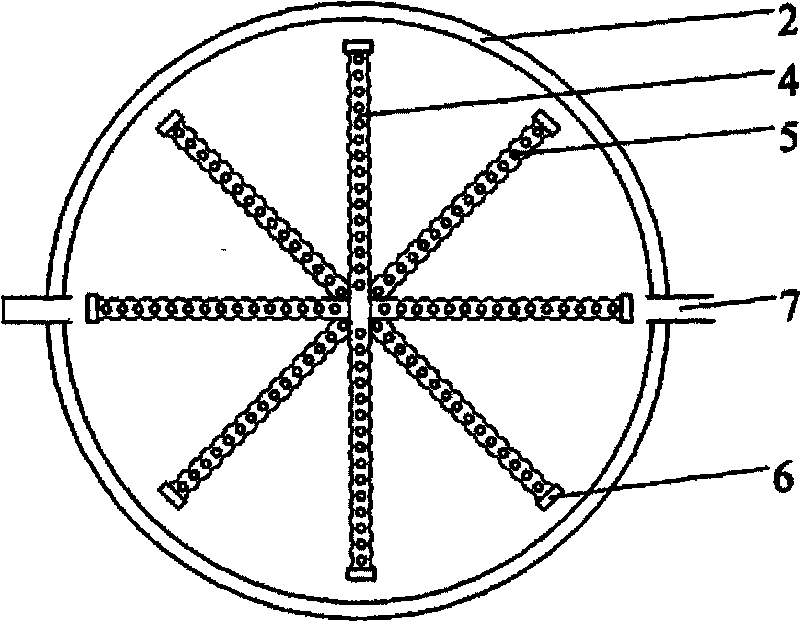

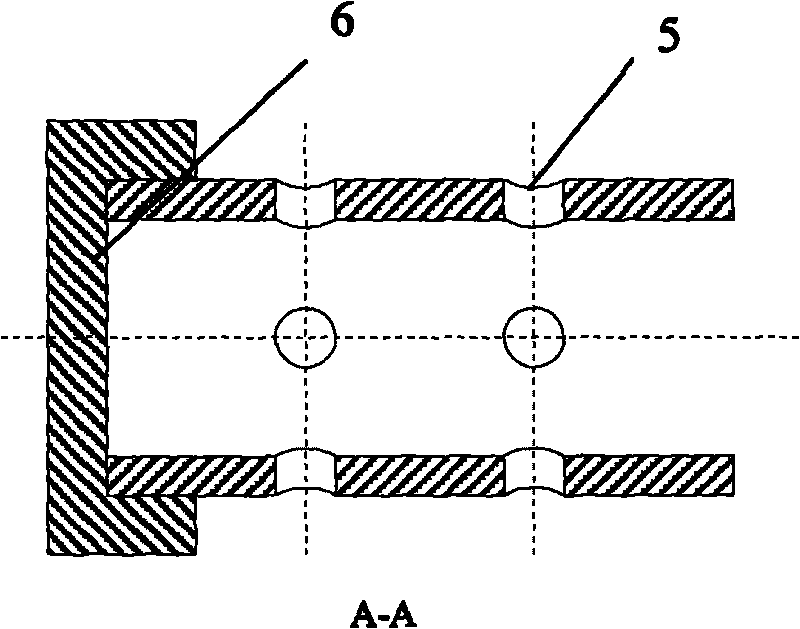

[0018] Such as figure 1 , 2 As shown, an extraction kettle 10 includes a cylindrical body 2 and a fluid distributor 9 , the upper part of the cylindrical body 2 is provided with an outlet 7 , and the lower end is provided with an inlet 8 . The fluid distributor 9 is placed in the cylindrical body 2, which includes the main pipe 3 and the branch pipe 4. The upper end of the main shaft tube is closed, the lower end is provided with the main shaft tube inlet 1, and the lower end of the main shaft tube is arranged in the cylindrical body inlet 8. Such as image 3 and 4 As shown, there are openings 5 through the wall of the branch pipe at regular intervals on the branch pipe 4, and the end of the branch pipe 4 is closed with a plug 6.

[0019] Such as figure 1 , 2 As shown, the main shaft tube 3 is vertically connected with the branch pipes 4 and connected internally. A layer of branch pipes is arranged at a certain distance on the main shaft pipe 3. There are 4 layers of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com