Metal heat-treatment controllable slow-cooling device and intelligent on-line monitoring system

A metal heat treatment and slow cooling device technology, applied in heat treatment process control, heat treatment equipment, manufacturing tools, etc., can solve the problems of poor slow cooling effect and easy pollution of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

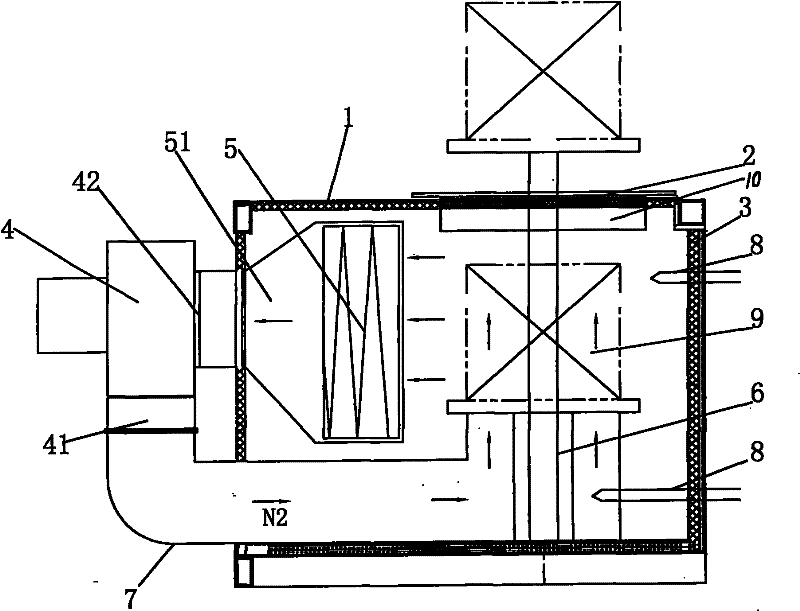

[0032] figure 1 A controllable slow cooling device for metal heat treatment constituting Embodiment 1 of the present invention.

[0033] refer to figure 1 , the controllable slow cooling device for metal heat treatment involved in this embodiment includes a furnace body 1 and a blower fan 4, the inner chamber of the furnace body 1 is provided with a lifting / lowering platform 6, a heat exchanger 5 and a temperature detector 8; the furnace body 1 The upper side wall is provided with a workpiece inlet / outlet 10, and a sealing cover 2 is arranged at the workpiece inlet / outlet 10; the air outlet 41 of the fan is connected to the inner cavity of the furnace body 1 from the lower side, and the return air outlet 42 of the fan is connected from the upper side. Connected to the air outlet 51 of the heat exchanger in the furnace body, a one-way air duct is formed between the inner cavity of the furnace body 1, the air outlet 41 of the fan and the air inlet of the heat exchanger 5, and t...

specific Embodiment 2

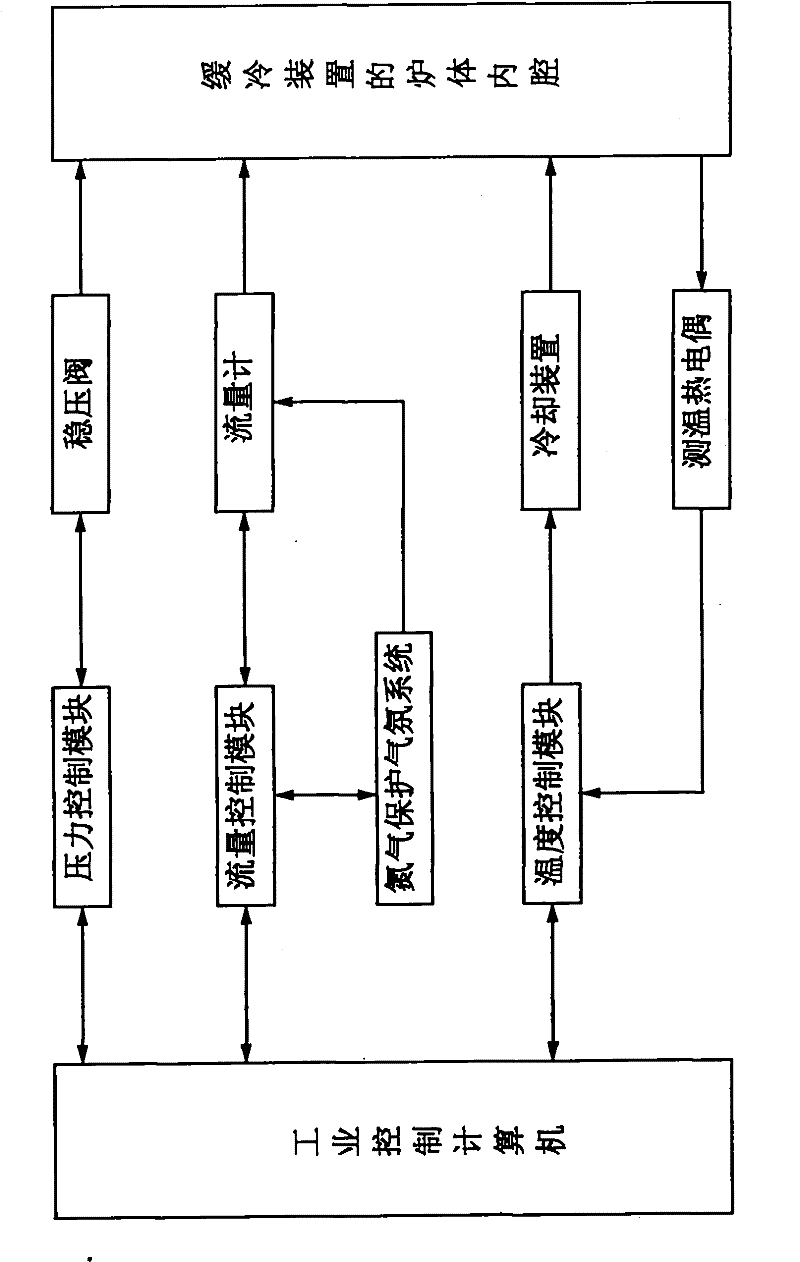

[0039] figure 1 and figure 2 Constitute the metal heat treatment controllable slow cooling intelligent online monitoring system of the present invention.

[0040] refer to figure 2 , metal heat treatment controllable slow cooling intelligent online monitoring system, is in figure 1 An industrial computer control system is connected on the basis of the disclosed metal heat treatment controllable slow cooling device, which mainly includes: a temperature control module connected to the control input signal ends of the aforementioned fan 4, heat exchanger 5 and lifting mechanism 6, the temperature control module The signal output terminals of the temperature control module are respectively connected to the control input signal terminals of the fan 4, the heat exchanger 5 and the lifting mechanism 6, the feedback signal input terminals of the temperature control module are connected to the signal output terminals of the temperature detector 8, and the control signal input termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com