Low-heat shrinkage geogrid and preparation method thereof

A geogrid and low-heat technology, applied in sea area engineering, water conservancy engineering, coastline protection, etc., can solve the problems that cannot be used in the dam bottom of pumped storage power stations, etc., and achieve good load transfer performance, reduce wear, and high load capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

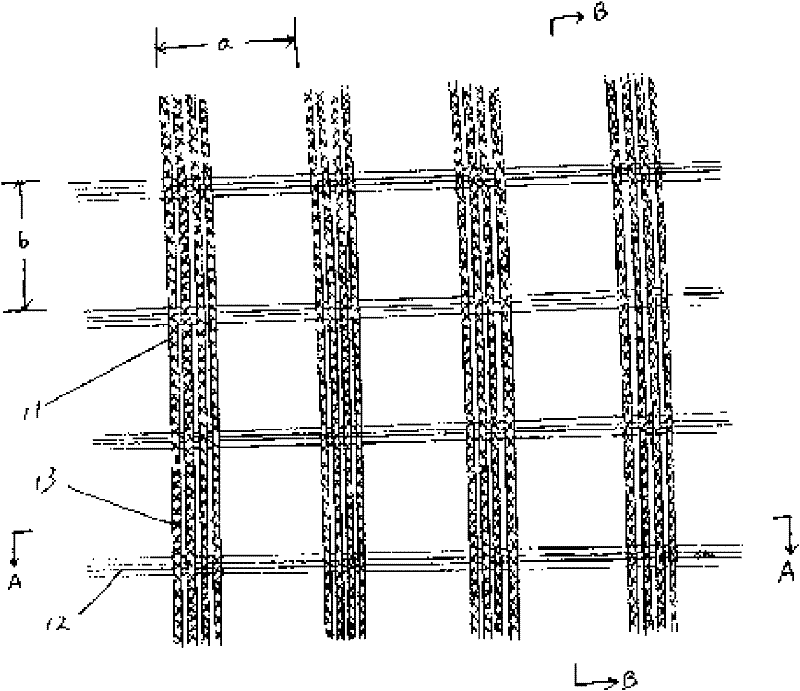

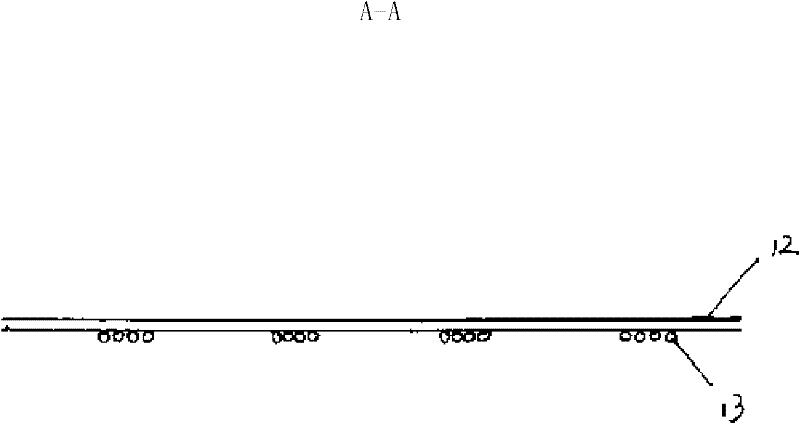

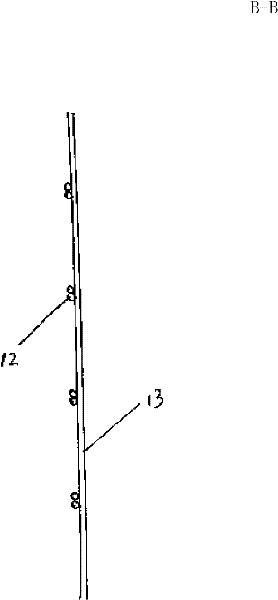

[0019] See Figure 1 to Figure 4 , The low thermal shrinkage geogrid of this embodiment has a mesh gray cloth 1 and reinforcements. Net fabric 1 is to be made by four groups of warp yarns 11 and two groups of weft yarns 12 by knitting chain lines 13 through a warp knitting machine. The reinforcement is arranged around the mesh gray cloth 1, and is bonded and fixed on the monofilaments of the warp yarn 11 and the weft yarn 12 of the mesh gray cloth 1 and between these monofilaments, so that the mesh gray cloth 1 and the reinforcement are bonded together to form a e s.

[0020] The material of the warp yarn 11 and the weft yarn 12 in the mesh gray cloth of the present embodiment is high-strength high-modulus polyester fiber tow, and the material of the used chain thread 13 is high-strength low-shrinkage polyester filament.

[0021] In this embodiment, the monofilament surface of the warp yarn 11 and the weft yarn 12 is coated with a wear-resistant oil agent composed of unsatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com