Forecasting method of creep life of high-temperature material

A creep life, high temperature material technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problem of inability to accurately predict the creep life of high temperature materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

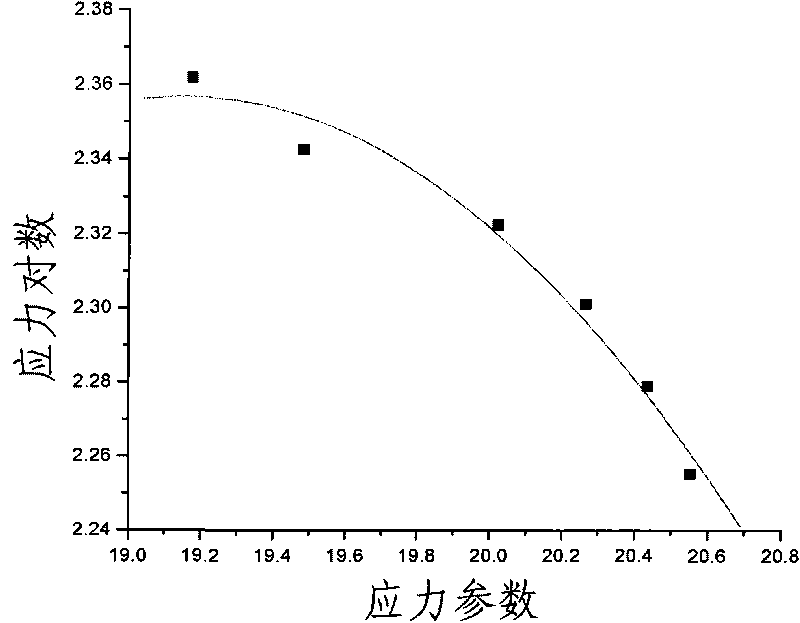

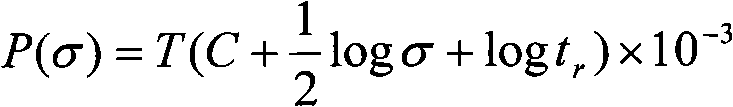

[0079] The creep life prediction method of the high-temperature material of the present invention and the traditional L-M method are used to compare the creep durability life prediction of the pearlitic heat-resistant steel 12Cr2MoWVTiB alloy under 150Mpa stress.

[0080] Obtain data on material properties at different temperatures:

[0081] The test is carried out according to GB / T2039-1997 "Metal Tensile Creep and Durability Test Method". Sample size: the standard diameter of the round bar sample is φ10mm and φ8mm, and the calculated length is 100mm; the plate-shaped sample has a width of 15mm, a thickness of 1-3mm, and a calculated length of 100mm.

[0082] The test equipment is a durable strength testing machine. The machine should be composed of the following parts: heating furnace and temperature measurement and control system; loading device, sample clamping, lifting and automatic control system; creep deformation measurement system. The accuracy of the load of the te...

Embodiment 2

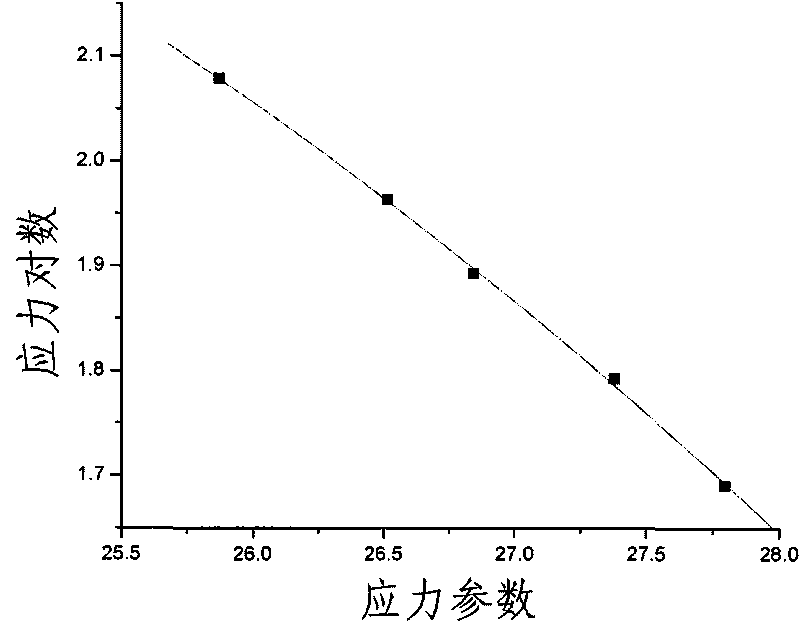

[0097] The creep life prediction method of the high-temperature material of the present invention is compared with the traditional L-M method to predict the creep durability life of the Hastelloy nickel-based alloy under 41Mpa stress.

[0098] Obtain data on material properties at different temperatures:

[0099] The test is carried out according to GB / T2039-1997 "Metal Tensile Creep and Durability Test Method". Sample size: the standard diameter of the round bar sample is φ10mm and φ8mm, and the calculated length is 100mm; the plate-shaped sample has a width of 15mm, a thickness of 1-3mm, and a calculated length of 100mm.

[0100] The test equipment is a creep and endurance strength testing machine. The machine should be composed of the following parts: heating furnace and temperature measurement and control system; loading device, sample clamping, lifting and automatic control system; creep deformation measurement system. The accuracy of the load of the testing machine is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com