AC-AC frequency-conversion wind power generating system for semi-direct driving sub-intermediate speed cage type rotor

A technology of wind power generation system and cage rotor, which is applied in wind power generation, control of generators through magnetic field changes, and AC network to reduce harmonics/ripples, etc. To solve the problem of overcapacity, reduce system loss and improve unit utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

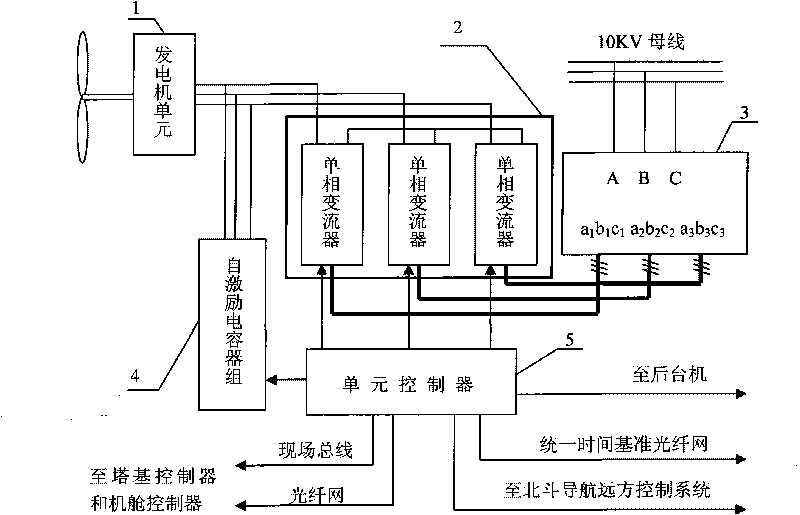

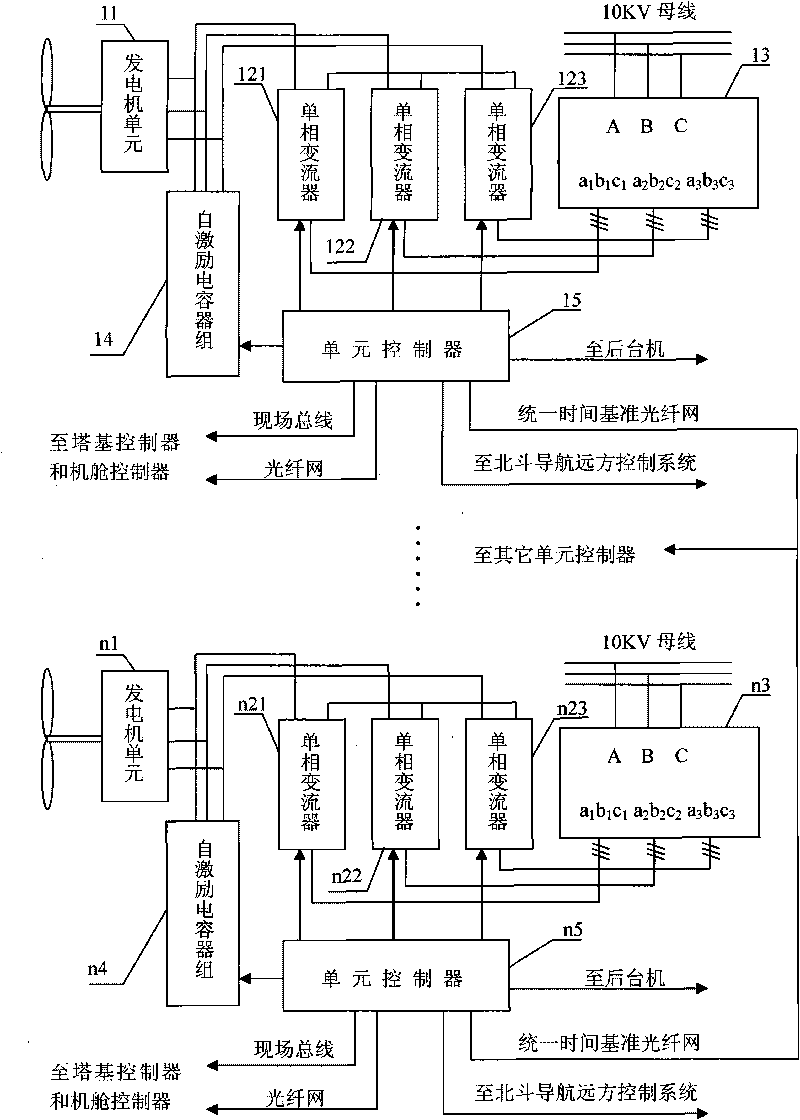

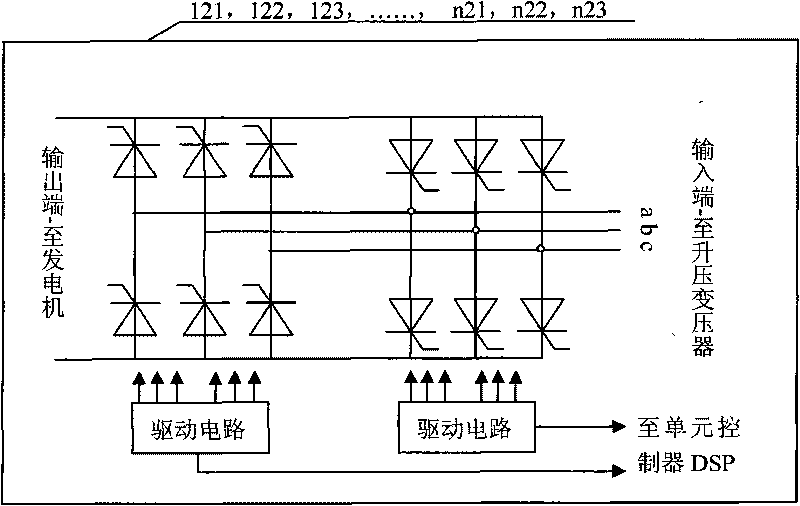

[0031] Such as figure 1 , 2 As shown, the semi-direct drive sub-medium-speed cage rotor AC-AC frequency conversion wind power generation system of the present invention includes n cage-type rotor asynchronous generator units 1, three-phase AC-AC converter 2, and Y-extended edge connection step-up transformer 3. The adjustable self-exciting capacitor group 4 and the unified time reference unit controller 5 constitute a sub-system with the same structure, in which the cage-type rotor asynchronous generator unit 1 is connected with the three-phase AC-AC converter 2 and the adjustable self-exciting capacitor group respectively 4 connections, the three-phase AC-AC converter 2 is connected to the Y-extended edge connection step-up transformer 3, and the output end of the unified time reference unit controller 5 is respectively connected to the three-phase AC-AC converter 2 and the adjustable self-excitation capacitor group 4 At the input end, n unified time reference unit controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com