Co-production device for producing hydrocarbon through methanol dehydration as well as cold, heat and power

A technology of methanol dehydration and cold and thermal electricity, which is applied in steam engine installations, lighting and heating equipment, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of large carbon dioxide emissions and low thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

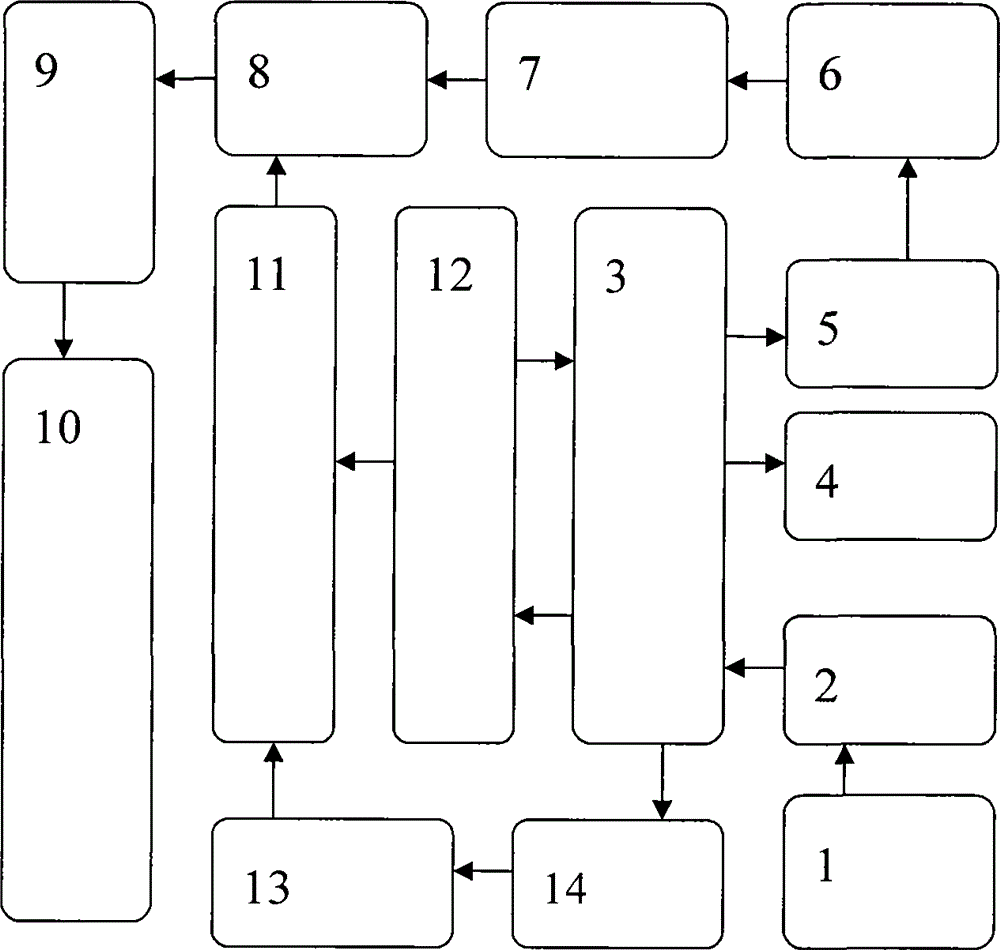

Image

Examples

Embodiment 1

[0006] Example 1: The dehydration hydrocarbon production system produces 10,000 tons of gasoline and liquefied gas per year, and consumes 25,000 tons of methanol. About 2,500 tons of diesel oil or liquefied petroleum gas can be matched with cooling and heating devices for the production of cooling and heating power. Suitable for building in small towns.

Embodiment 2

[0007] Example 2: The dehydration hydrocarbon production system produces 100,000 tons of clean gasoline and liquefied gas annually, and consumes 250,000 tons of methanol. It can be equipped with a cooling, heating and power cogeneration device with an annual consumption of 25,000 tons of diesel oil, and is suitable for supporting services for central cities and development zones.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com