Non-autoclaved and unburned brick and preparation method thereof

A press molding and cement technology, applied in the field of double-free bricks and their preparation, can solve the problems of being susceptible to climate influence and air pollution, endangering human survival, energy and manpower, etc., achieving significant environmental and social benefits, reducing resource damage, The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

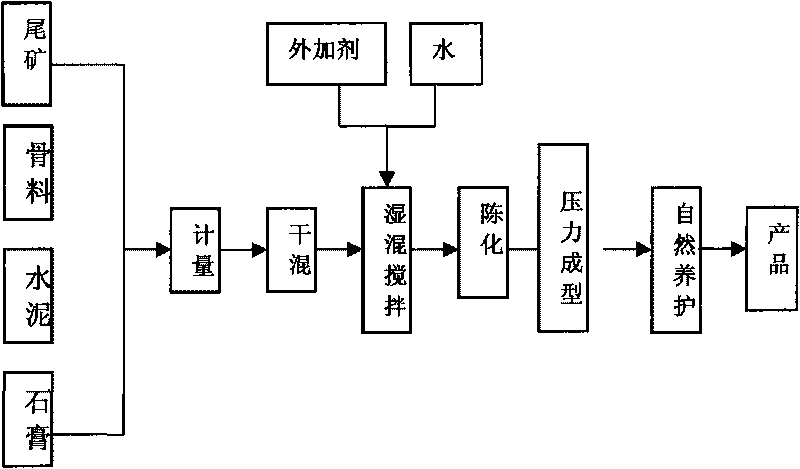

Method used

Image

Examples

Embodiment 1

[0038] Double-free bricks, which are made of high-phosphorus hematite tailings, cement, aggregate, gypsum, composite admixtures and water, and then pressed and cured; among them, high-phosphorus hematite tailings, cement, aggregate The mass percentages of high-phosphorus hematite tailings, cement, aggregate and gypsum accounted for by each raw material of gypsum are:

[0039] High phosphorus hematite tailings 78%,

[0040] cement 10%,

[0041] Aggregate 10%,

[0042] Gypsum 2%;

[0043] The added amount of the composite admixture is 2.01% of the amount (mass) of the cement; the added amount of the water is 15% of the total mass of the high phosphorus hematite tailings, cement, aggregate and gypsum.

[0044] The aggregate is river sand with a particle size below 0.83mm.

[0045] The composite admixture is composed of triethanolamine and sodium sulfate, the mass ratio of triethanolamine and sodium sulfate is 0.01:2 (ie 0.01% triethanolamine, 2% sodium sulfate).

[0046] Hig...

Embodiment 2

[0057] Double-free bricks, which are made of high-phosphorus hematite tailings, cement, aggregate, gypsum, composite admixtures and water, and then pressed and cured; among them, high-phosphorus hematite tailings, cement, aggregate The mass percentages of high-phosphorus hematite tailings, cement, aggregate and gypsum accounted for by each raw material of gypsum are:

[0058] High phosphorus hematite tailings 80%,

[0059] cement 10%,

[0060] Aggregate 6%,

[0061] Gypsum 4%;

[0062] The added amount of the composite admixture is 2.07% of the amount (mass) of the cement; the added amount of the water is 10% of the total mass of the high phosphorus hematite tailings, cement, aggregate and gypsum.

[0063] The aggregate is river sand with a particle size below 0.83mm.

[0064] The composite admixture is composed of triethanolamine and sodium sulfate, and the mass ratio of triethanolamine to sodium sulfate is 0.07:2 (ie 0.07% triethanolamine, 2% sodium sulfate).

[0065] H...

Embodiment 3

[0076] Double-free bricks, which are made of high-phosphorus hematite tailings, cement, aggregate, gypsum, composite admixtures and water, and then pressed and cured; among them, high-phosphorus hematite tailings, cement, aggregate The mass percentages of high-phosphorus hematite tailings, cement, aggregate and gypsum accounted for by each raw material of gypsum are:

[0077] High phosphorus hematite tailings 78%,

[0078] Cement 15%,

[0079] Aggregate 5%,

[0080] Gypsum 2%;

[0081] The added amount of the composite admixture accounts for 2.05% of the cement amount (mass); the added amount of water accounts for 12% of the total mass of the high phosphorus hematite tailings, cement, aggregate and gypsum.

[0082] The aggregate is crushed stone with a particle size below 0.83mm.

[0083] The composite admixture is composed of triethanolamine and sodium sulfate, and the mass ratio of triethanolamine to sodium sulfate is 0.05:2 (ie 0.05% triethanolamine, 2% sodium sulfate)....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com