Epitaxial reaction chamber cleaning method capable of improving epitaxial quality and reducing cost

A reaction chamber and epitaxy technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of wafer carrier plate damage, increase epitaxy cost, increase surface particle diffusivity, etc., to improve epitaxy quality, reduce cost, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The method for cleaning the epitaxial reaction chamber which can improve the epitaxial quality and reduce the cost of the present invention will be further described in detail below.

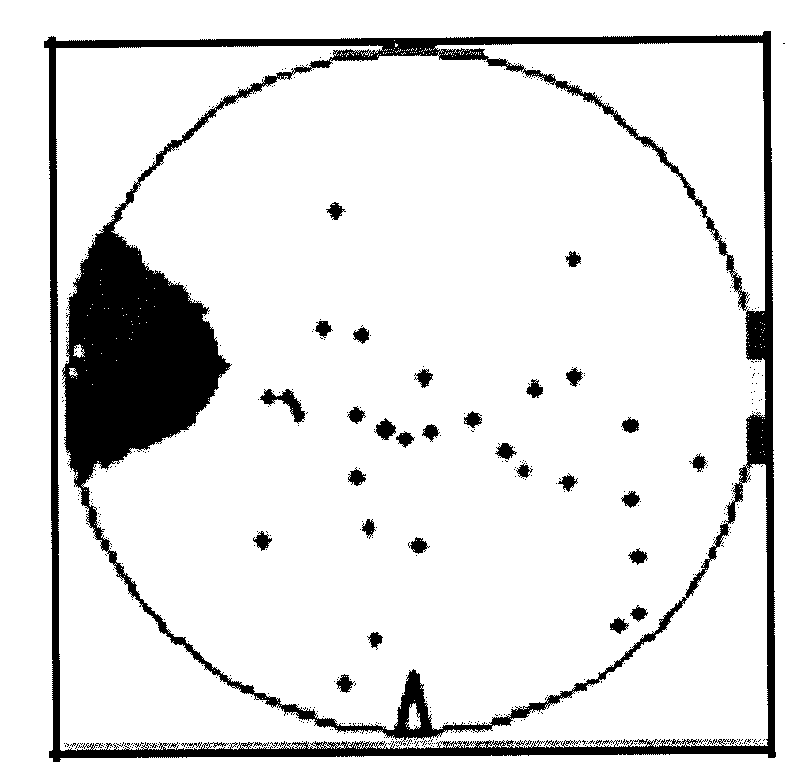

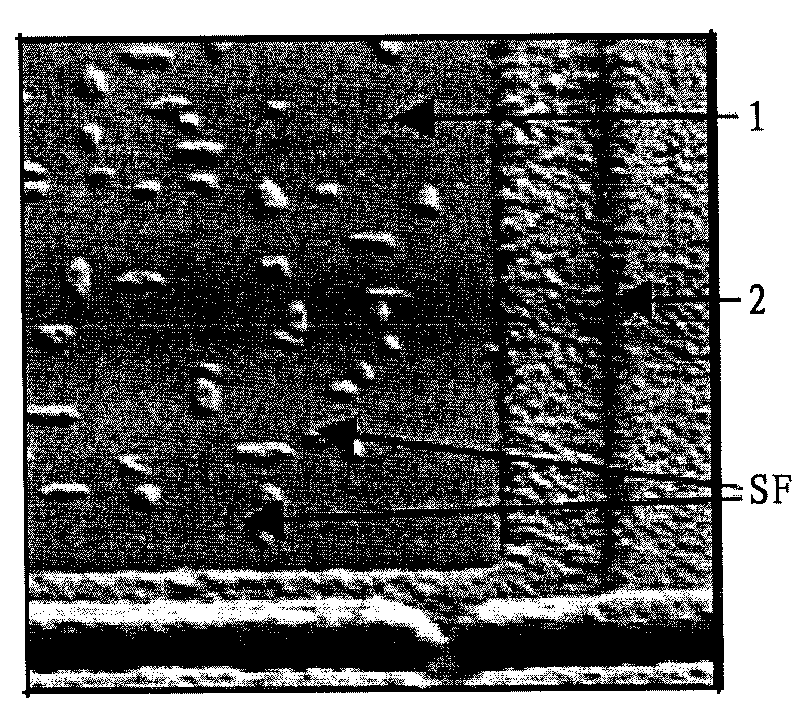

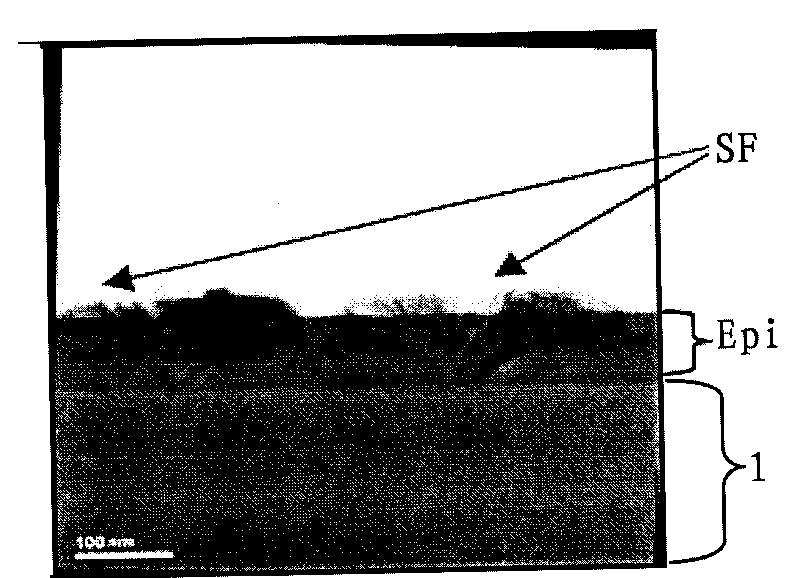

[0027] The epitaxial reaction chamber cleaning method which can improve the epitaxial quality and reduce the cost of the present invention is carried out before or after the epitaxial process. The epitaxial reaction chamber is a reaction chamber of a decompression chemical vapor deposition machine. Round carrier tray. In this embodiment, the reduced-pressure chemical vapor deposition machine is an Epi Centura epitaxy system launched by Applied Materials Inc.

[0028] The characteristics of the Epi Centura epitaxy system are: A. The wafer is set on the wafer carrier on the base and rotates with the base. By adjusting the level and height of the base, the thickness and resistance of the epitaxy grown on the wafer can be adjusted. The uniformity of the efficiency can be well guaranteed; B. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com