Ultra wide band cavity filter

A cavity filter, ultra-wideband technology, applied in the field of filters, can solve problems such as insertion loss and parasitic passband shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

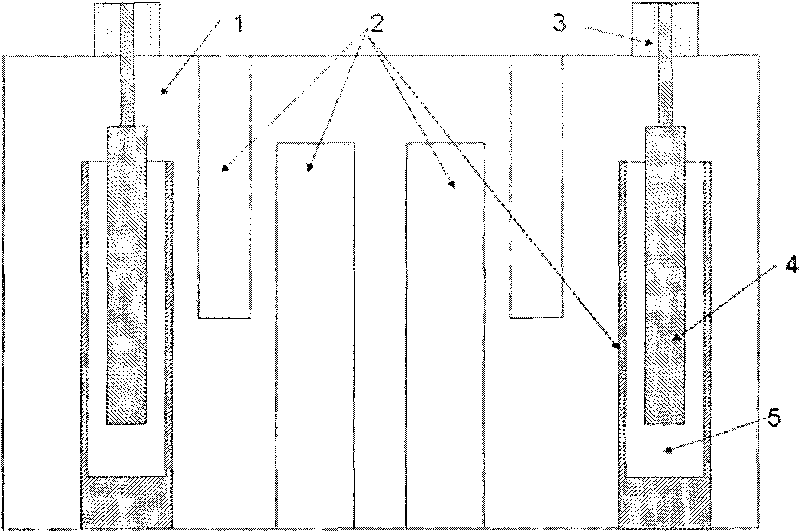

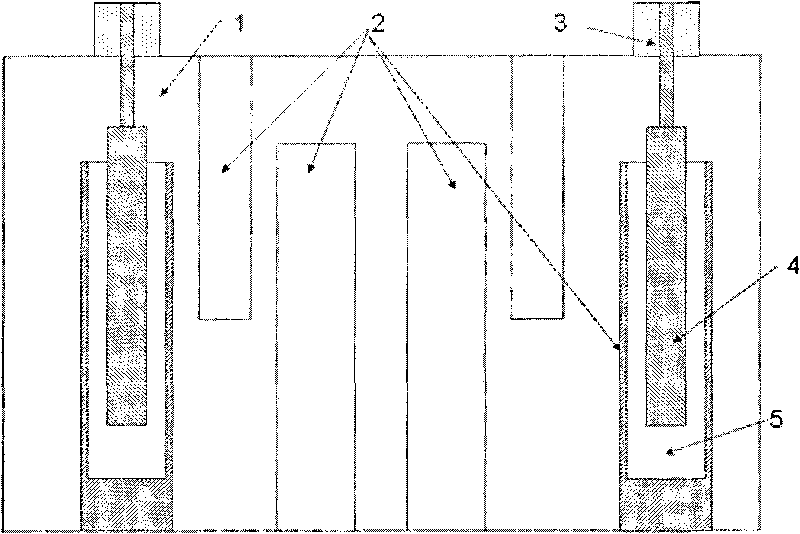

[0018] Such as figure 1 As shown, the ultra-wideband cavity filter includes a cavity 1, a resonant metal column 2 arranged in the cavity 1, and two input-output structures 3 arranged on the cavity 1, and the number of the resonant metal columns is six, The two input and output structures 3 are respectively provided with an inner conductor entering the cavity 1 , and the front end of each inner conductor extends into a resonant metal column 2 .

[0019] The resonant metal column 2 containing the inner conductor is provided with a cylindrical groove 5 , and the front end of the inner conductor extends into the groove 5 .

[0020] The front end of the inner conductor is also provided with a cylindrical coupling metal column 4 , which has a gap with the side wall and the bottom surface of the groove 5 . The coupling metal post 4 is wrapped around the front end of the inner conductor and is insulated from the inner conductor.

[0021] Among all the resonant metal pillars 2 , four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com