Nitride-based semiconductor laser device and method of manufacturing the same

A technology of nitrides and laser components, which is applied in the direction of semiconductor lasers, structural details of semiconductor lasers, laser components, etc., can solve the ohmic properties of the p-side electrode layer (deterioration of contact resistance, increase of operating voltage of semiconductor laser components, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be described below based on the drawings.

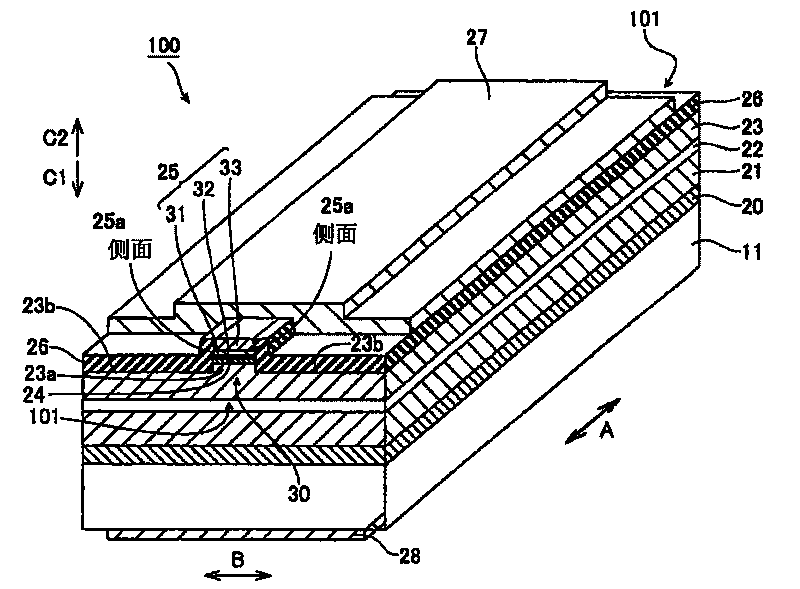

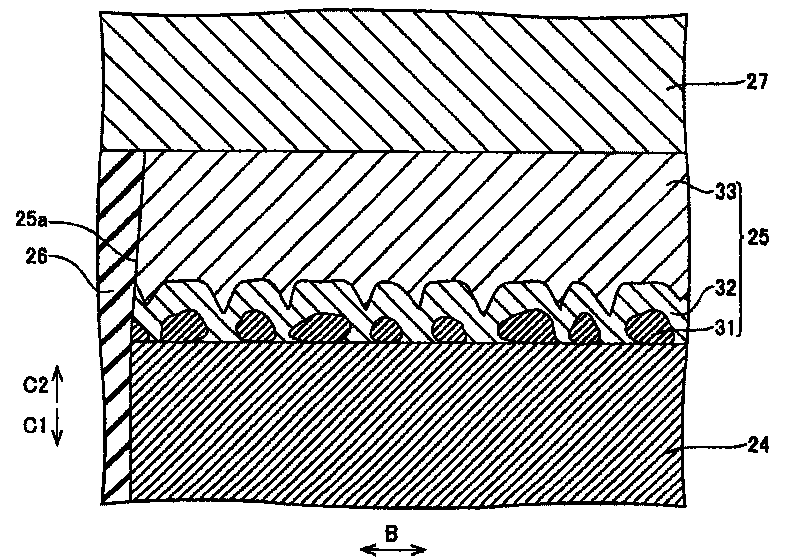

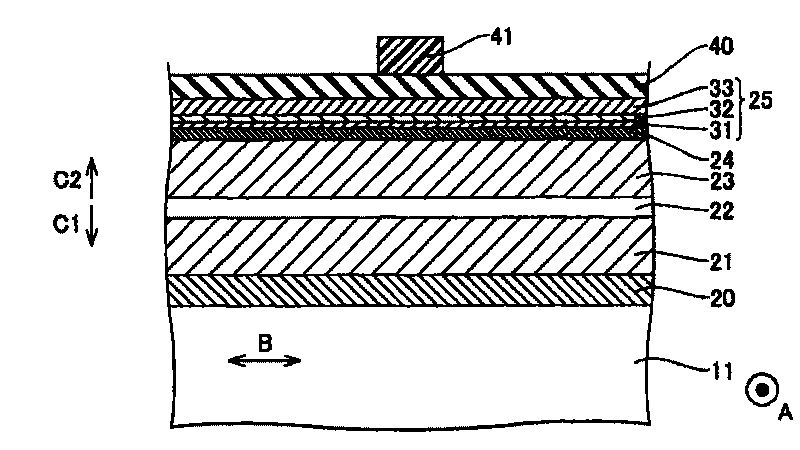

[0048] First, refer to figure 1 and figure 2 The structure of the nitride-based semiconductor laser device 100 according to one embodiment of the present invention will be described.

[0049] In the nitride-based semiconductor laser device 100 of the present embodiment, as figure 1 As shown, a buffer layer 20 made of AlGaN is formed on an n-type GaN substrate 11 . On the buffer layer 20, an n-type cladding layer 21 made of n-type AlGaN, a barrier layer (not shown) made of InGaN, and a well layer (not shown) made of InGaN are alternately stacked. layer 22, and a p-type cladding layer 23 made of AlInGaN and having a convex portion 23a and a flat portion 23b. A p-type contact layer 24 made of InGaN is formed on the convex portion 23 a of the p-type cladding layer 23 . In addition, the ridge 30 is formed by the convex portion 23 a of the p-type cladding layer 23 and the p-type contac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com