Intelligent controller of electric furnace electrode

A technology of intelligent controller and electric furnace electrode, which is applied in the direction of electric heating devices, electrical components, and energy efficiency improvement, and can solve problems such as limiting electric furnace control technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

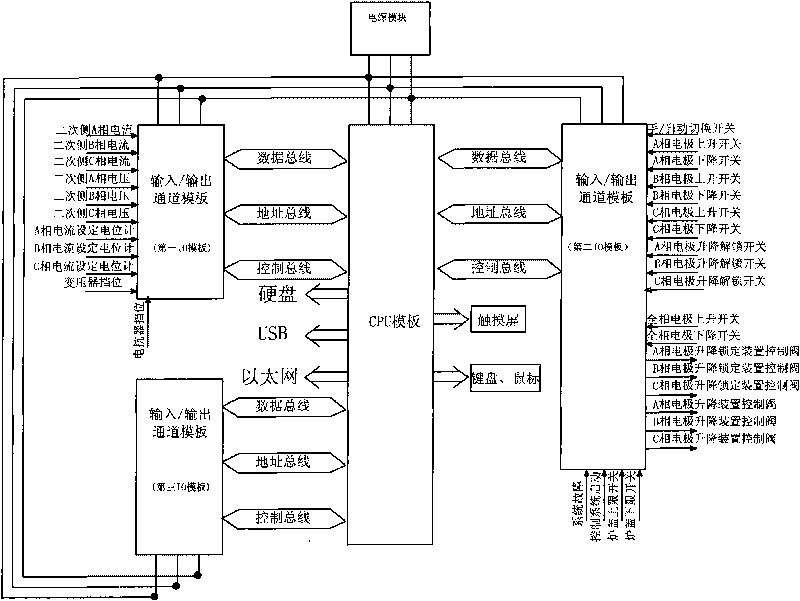

[0088] The electric furnace electrode intelligent controller includes hardware and software. The hardware part includes the box body 1 and the liquid crystal touch screen 2 installed on the box body 1, the single-board computer installed in the box body 1, and multiple digital / analog input and output. channel module.

[0089] The single-board computer adopts the model PC / 104-1621CLDN, and the digital / analog input and output channel module adopts the module 104-A726 with 16 digital inputs, 16 digital outputs and 6 analog output channels, and 32 analog input channels 104 -32ADT is stacked and inserted, and the LCD touch screen 2 adopts TPC-064. The corresponding terminal pins of the CPU chip of the single-board computer are respectively connected to the hard disk, DVD drive, keyboard, mouse, USB interface, touch screen display card and Ethernet card through wires, and all interfaces are fixedly installed outside the casing.

[0090] The multiple digital / analog input and output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com