Solid fruit-vegetable ripener

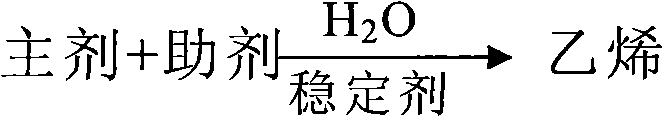

A ripening agent and solid technology, applied in the field of solid fruit and vegetable ripening agents, can solve the problems of shortened shelf life, long drying process, troublesome operation, etc., and achieve the effects of convenient transportation, convenient use and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Raw materials: 10 parts of 99.9% ethephon; 4 parts of potassium carbonate; 6 parts of sodium bicarbonate; 50 parts of talcum powder; 30 parts of white carbon black.

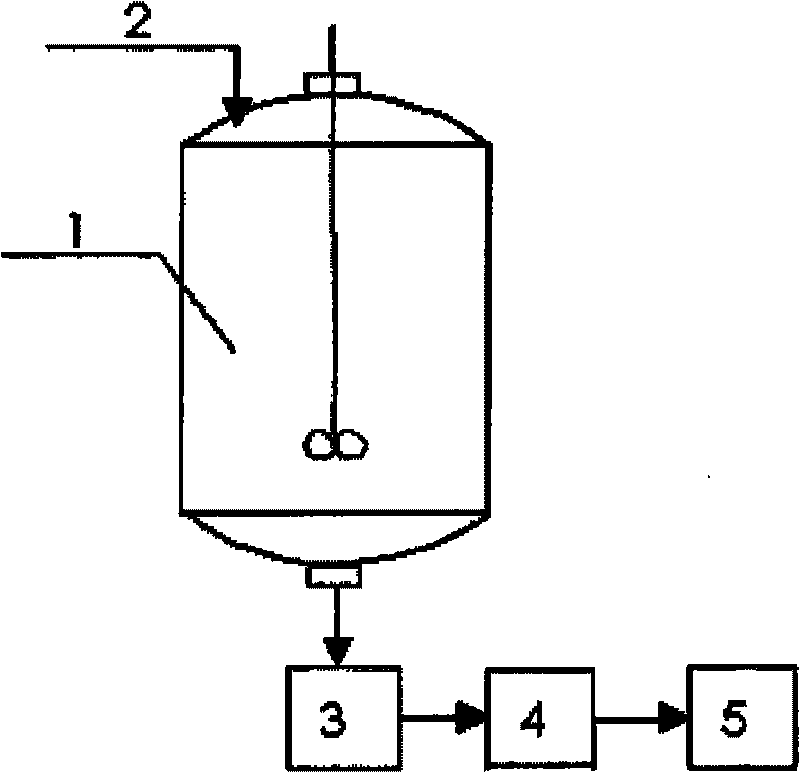

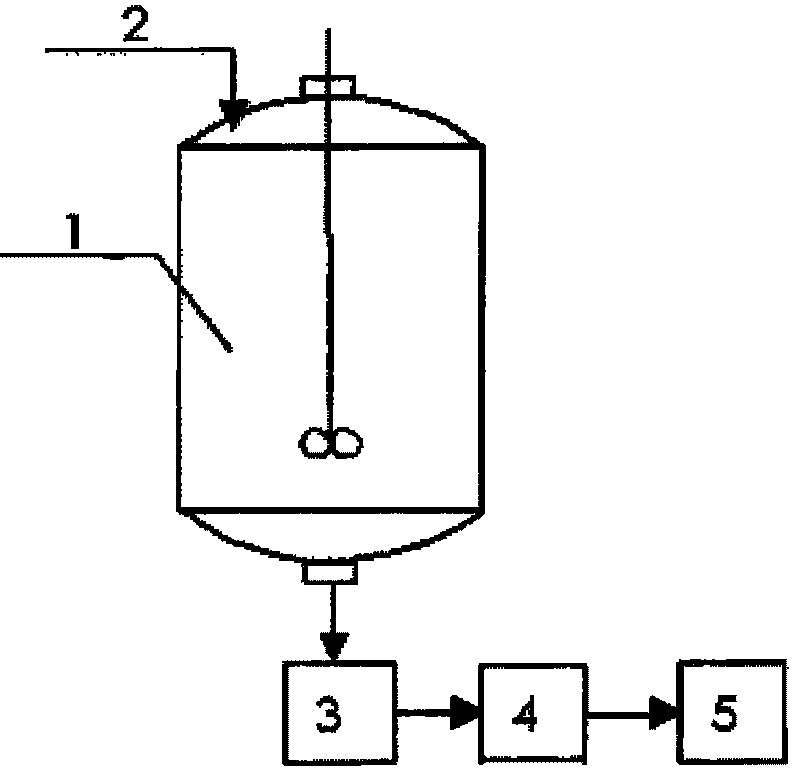

[0027] Preparation method: add 10 parts of main ingredient 99.9% ethephon; 4 parts of dried auxiliary agent potassium carbonate, 6 parts of sodium bicarbonate; 50 parts of dried stabilizer talcum powder and 30 parts of white carbon black, and add them through feeding port 2 respectively into the mixer 1, stirred at room temperature for 50 minutes, discharged, temporarily stored in a dry and sealed storage tank 3, and the obtained powder is a solid fruit and vegetable ripening agent. The powder is directly packaged 4 to be the finished product 5 .

[0028] The preparation method of product in the following examples is all the same as Example 1.

Embodiment 2

[0030] Raw materials: 20 parts of 99.9% ethephon; 6 parts of sodium hydroxide; 14 parts of potassium phosphate; 30 parts of talcum powder; 30 parts of starch

Embodiment 3

[0032] Raw materials: 10 parts of 99.9% ethephon; 5 parts of potassium hydroxide; 15 parts of sodium phosphate; 30 parts of white carbon black; 40 parts of diatomaceous earth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com