Hot stamping die of integrated cooling pipeline

A technology of hot stamping dies and cooling pipes, applied in the field of hot stamping, can solve the problems of complex cooling system structure and uneven cooling, and achieve the effects of reducing residual stress, simple processing and manufacturing, and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content and specific implementation methods of the present invention will be further described below in conjunction with the accompanying drawings.

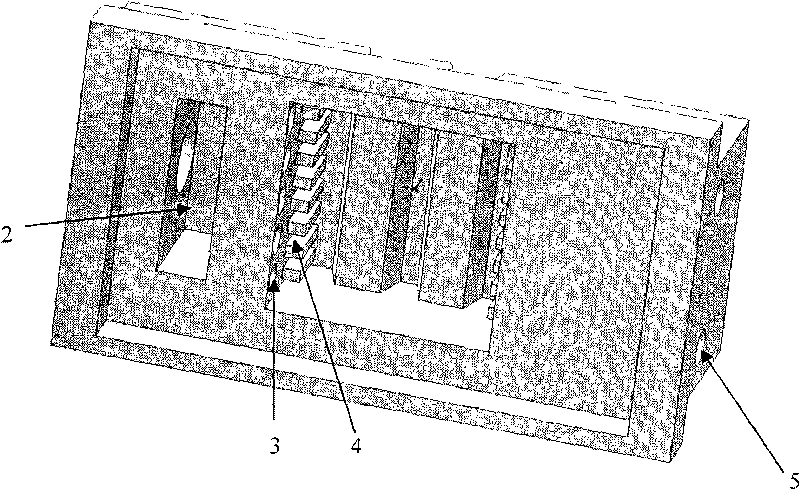

[0025] The cooling structure of the concave and convex molds and the cooling support block of the concave and convex molds of the present invention is the same as the cooling channel structure formed after the combination, so the structure of the concave mold is taken as an example for description below.

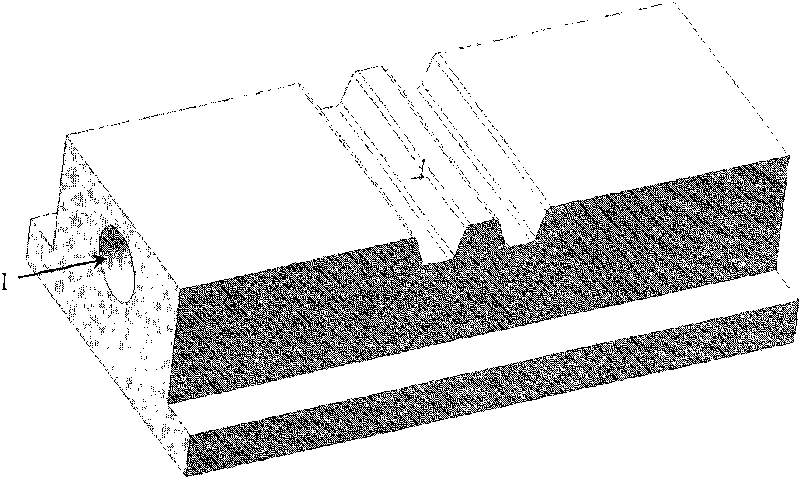

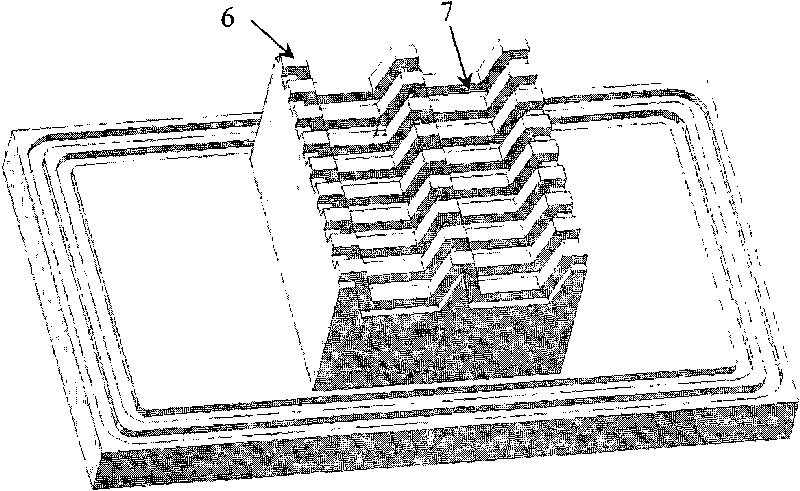

[0026] refer to figure 1 , figure 2 , image 3 with Figure 4 , the present invention combines the shape of the working surface of the die to design a series of internal distribution grooves 4, internal distribution chambers 8, straight cooling pipes 1, internal cooling pipes 4, internal cooling pipes 3, horizontal cooling pipes 2 and water outlets. The cross-sectional size of 5 satisfies the condition of full filling. Cooling grooves 7 and support protrusions 6 are arranged on the cooling support block of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com