Double selectivity efficient sulfur recovery device

A sulfur recovery and selective technology, applied in the preparation/purification of sulfur, can solve the problems of high operating cost, large floor space and large investment, and achieve the effect of reducing operating cost, saving land area and reducing investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

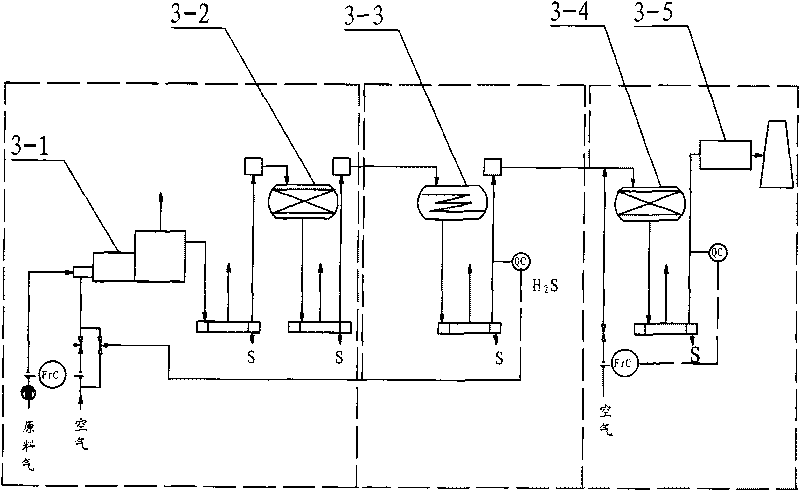

[0064] Such as Figure 4 As shown, a dual-selective high-efficiency sulfur recovery device includes sequentially connected in series combustion furnace and waste pot 4-1, primary Claus reactor 4-2, secondary Claus reactor and selective hydrogenation reactor 4-3. Three-stage selective oxidation reactor 4-4, deep desulfurization reactor 4-5, chimney 4-6;

[0065] Fill the peroxygen protection type and organosulfur hydrolysis type Claus catalyst in the primary Claus reactor 4-2;

[0066] In the two-stage Claus reactor 4-3, two different catalysts are loaded in two stages, and the Claus catalyst is loaded in the upper stage to continue the Claus reaction The lower section is loaded with a highly selective direct hydrogenation reduction catalyst, and the unreacted SO in the upper layer is 2 Direct hydrogenation reduction to elemental sulfur instead of H at a lower temperature of 200-220°C 2 S.

[0067] A low-temperature selective direct oxidation catalyst is loaded in the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com