Technology for preparing desulfurizing agent ammonia water in sintering flue gas desulfurization by coking residual ammonia water

A technology for coking residual ammonia water and sintering flue gas, which is applied in the preparation/separation of ammonia, chemical instruments and methods, and separation of dispersed particles to achieve the effects of small impact, mature technology, and reduced treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

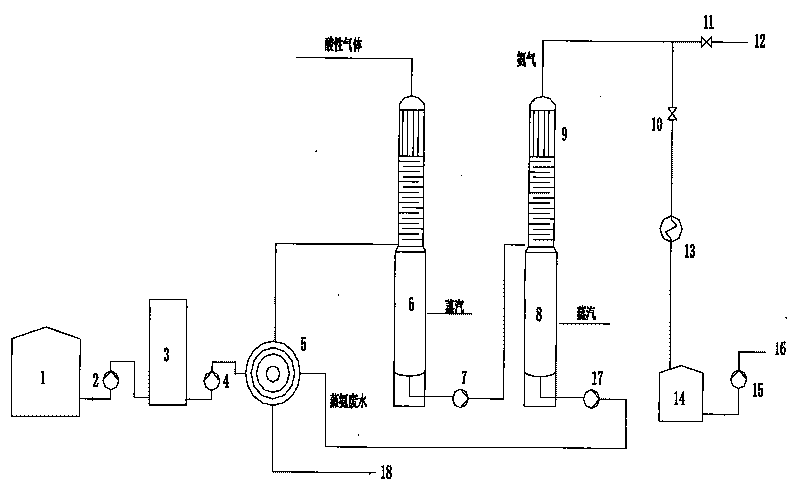

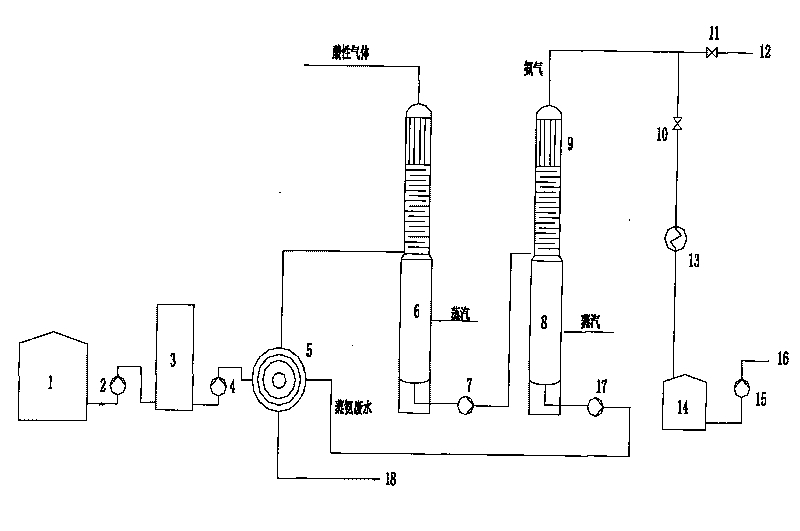

[0023] Below in conjunction with accompanying drawing, the present invention will be further described:

[0024] A process for preparing ammonia water desulfurization agent in sintering flue gas desulfurization by utilizing coking residual ammonia water, adopting coking residual ammonia water in the ammonia distillation tower 8 ammonia splitter 9 in the coking coal gas purification system as the desulfurizing agent ammonia water in sintering ammonia method flue gas desulfurization The source is to add a condensing cooler 13 after the ammonia distillation tower 8 and the ammonia splitter 9, and add a deacidification tower 6 before the ammonia distillation tower 8 and after the heat exchanger 5. The specific process steps are as follows:

[0025] (1), in the coking gas purification system, the remaining ammonia water in the remaining ammonia water storage tank 1 passes through the remaining ammonia water delivery pump 2, and after removing the tar through the tar remover 3, pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com