Spiral pyrolysis reactor

A technology of pyrolysis reactor and spiral, applied in the direction of direct heating dry distillation, special form dry distillation, petroleum industry, etc., can solve the problems of large size, large heat loss, difficult adjustment of reaction time, etc., and achieve simplified structure and process flow, sealing The effect of good performance and excellent working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

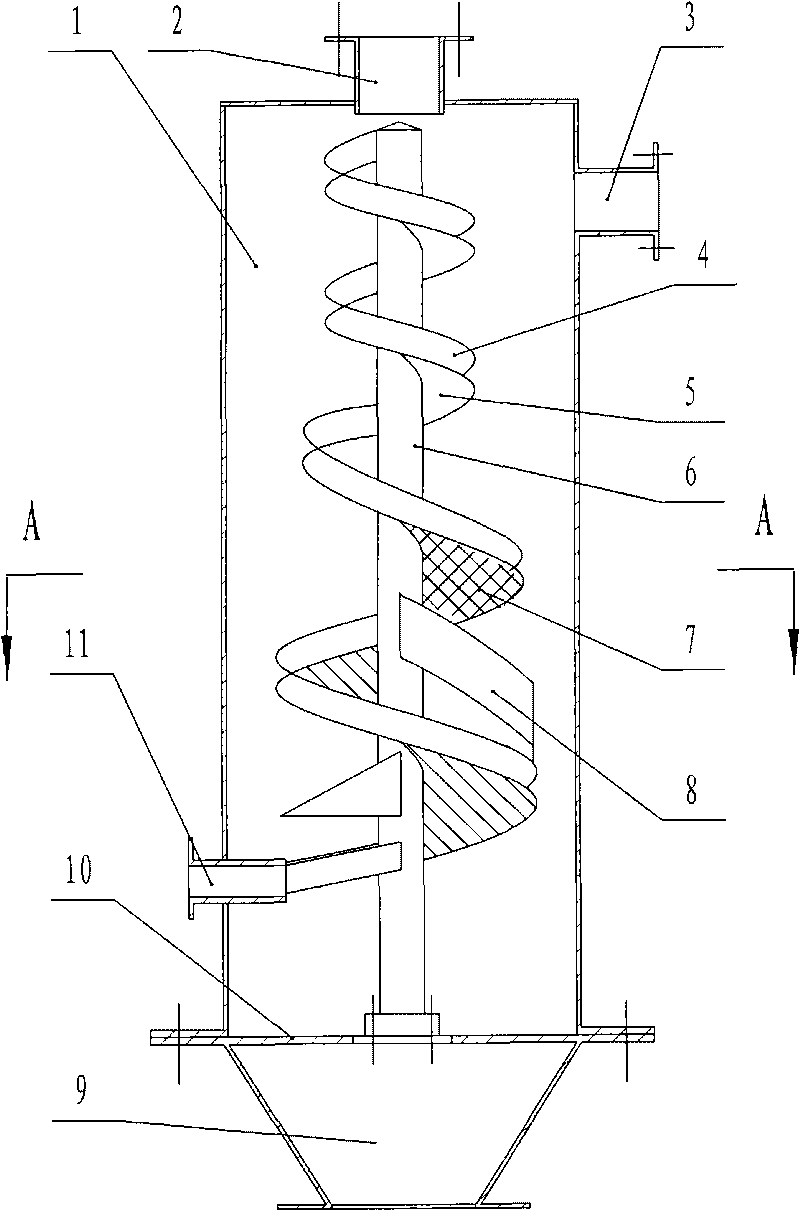

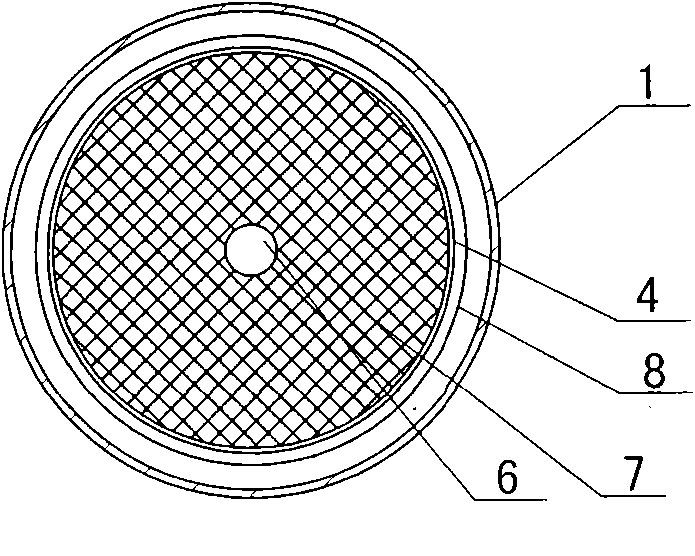

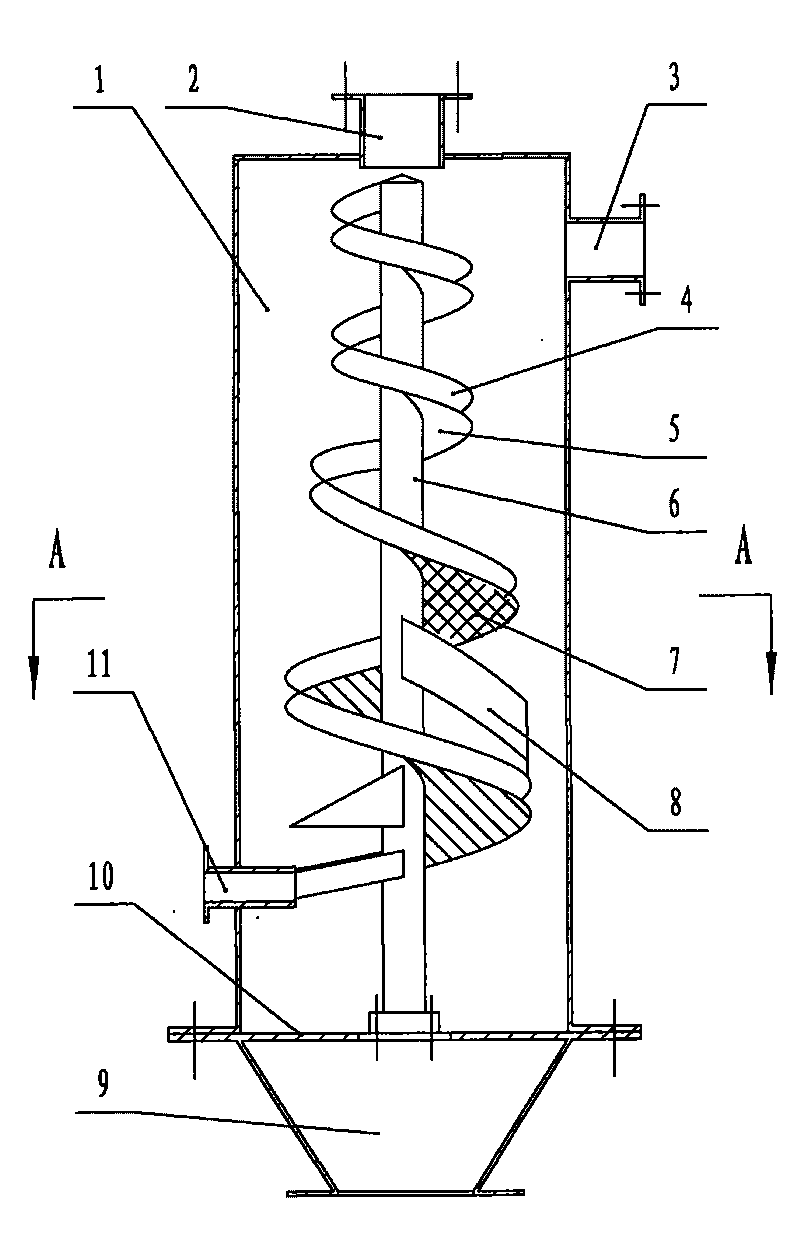

[0016] Including the shell 1, the top center of the shell 1 is provided with a feed inlet 2, the side wall of the upper end is provided with a pyrolysis gas outlet 3, the side wall of the lower end is provided with a heat carrier outlet 11, and the bottom is provided with a carbon powder outlet 9 A vertical shaft 6 is fixed in the center of the housing 1 and below the feed port 2 , and the bottom of the vertical shaft 6 is fixed in the center of the housing 1 via a bracket 10 . A spiral baffle 4 with gradually larger diameter is set on the vertical shaft 6, and a spiral bottom plate 5 is fixed and sealed between the bottom of the spiral baffle 4 and the vertical shaft 6 upwards from the middle of the vertical shaft 6, and downwards from the middle of the vertical shaft 6. A spiral screen 7 is fixed between the bottom and the vertical shaft 6. The spiral baffle 4 forms a bottom-sealed and bottom-unsealed spiral slideway with the spiral bottom plate 5 and the spiral screen 7 resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com