E-shaped fastener constrained type assembled buckling-restrained energy-consumed brace

An anti-buckling, energy-consuming, assembly-type technology, applied in the direction of earthquake resistance, building components, building structures, etc., can solve the problems of high production cost, brittle surrounding materials, complicated production process, etc., and achieve easy processing and installation, and reduce structure Cost-effective, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

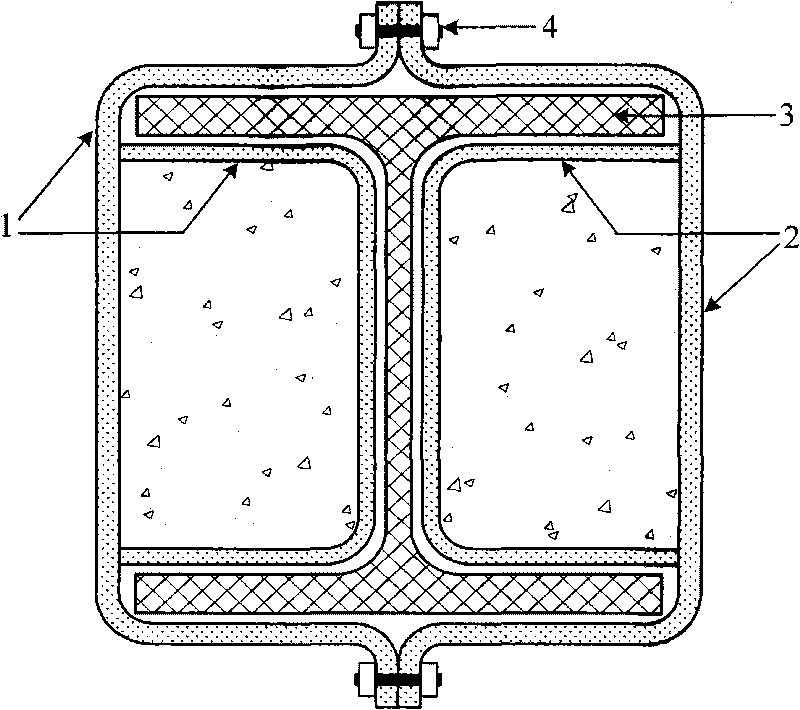

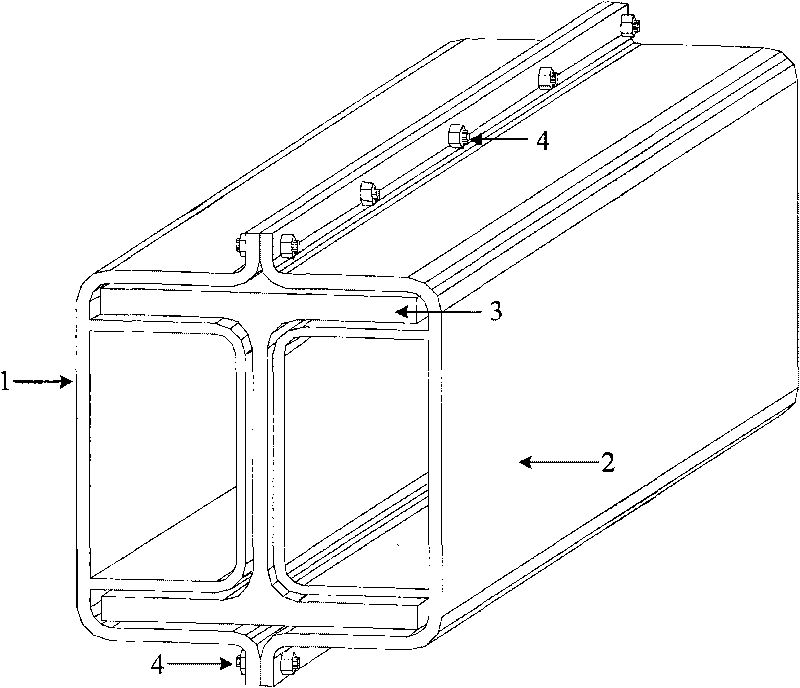

[0016] in such as figure 1 ~4 middle:

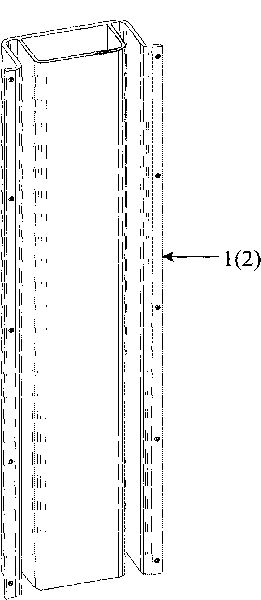

[0017] 1-"Giant" shaped fastener 1

[0018] 2-"Giant" shaped fastener 2

[0019] 3- Hot-rolled H-beam

[0020] 4-bolt

[0021] Such as figure 1 and figure 2 As shown, the anti-buckling energy-dissipating support consists of two "giant"-shaped fasteners 1-2 and a core hot-rolled H-shaped steel 3. The two "giant"-shaped fasteners 1-2 are respectively welded by a hat-shaped cold-formed thin-walled steel and a groove-shaped cold-formed thin-walled steel embedded in the hat-shaped cold-formed thin-walled steel; The zigzag fasteners 1 and 2 respectively have a closed rectangular tube, and concrete should be poured into the closed rectangular tube; the two "giant" zigzag fasteners 1 and 2 are connected together by bolts at the brim of the cap to form a peripheral restraint member. ""-shaped fasteners 1 to 2 form an H-shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com